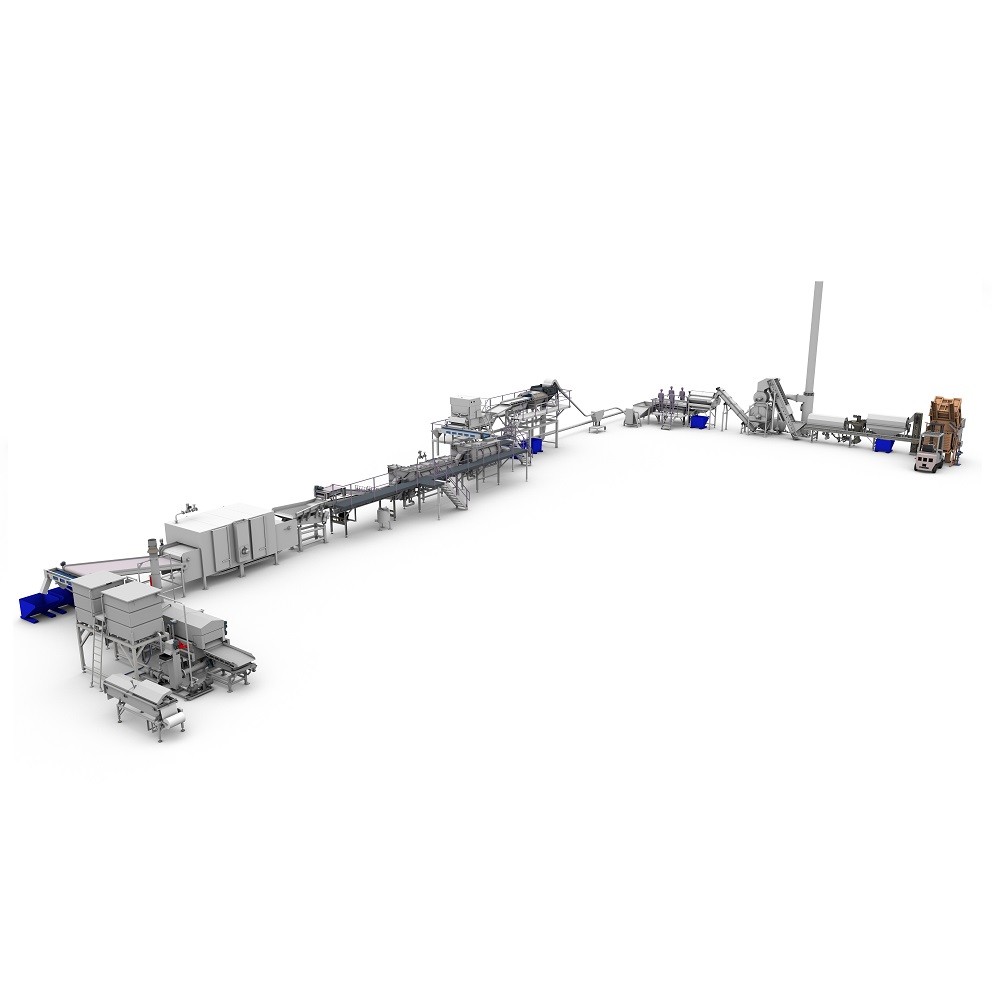

French fries processing line

Mass-producing french fries from raw potatoes requires a series of steps and various equipment for cleaning, drying, peeling, cutting, and frying, each presenting its own technical challenges. Bringing together all these processes involves the integration of multiple machines into a unified system, requiring effective communication among them to ensure a seamless and efficient operation.

All-in-one processing system for turning raw potatoes into French fries

The French fries plant from Kuipers is a complete turnkey solution for producing a range of potato-based products, including French fries, potato wedges, skin-on fries, and pomme Parisienne, starting from raw potatoes. The plant encompasses essential processes such as washing, peeling, cutting, sorting, blanching, drying, and frying.

The washed potatoes undergo initial cleaning in a rotating cage to separate soil and sprouts. A cyclone destoner with adjustable water flow removes stones that can create damage downstream. Next, a rod washer eliminates mud before the potatoes are exposed to high-pressure steam, which minimizes product loss during peeling. Subsequently, rotating nylon brushes remove the potato skin without the need for water. Roller inspection visually examines potatoes for defects that can be manually trimmed. Kuipers introduces a smart integration of hydro and mechanical cutting systems, enabling the production line to handle various cutting shapes and sizes efficiently with rapid changeovers.

Blanching uses a two-stage blancher. The first stage pre-gelatinizes the starch, inactivates enzymes, and opens up the starch cells. The second stage completes gelatinization and releases as much reducing sugars as possible. SAPP (Sodium Acid Pyrophosphate) solution is added to the product to prevent discoloration at later stages. Drying the potato strips is essential for proper product texture and lower oil absorption during frying. Additionally, the drying process plays a significant role in determining the moisture content of the end product.

A continuous fryer with adjustable temperatures and retention times handles the frying step. Additionally, a de-fatting shaker uses specific vibration movements to remove a significant amount of frying oil while keeping the bottom pan heated to recover the used oil easily.

Benefits

- Output capacity range of 1 to 5 tons per hour

- Complete processing system from raw potatoes to cooked French fries

- Low frying oil turnover time

- Standard cut 7x7, 10x10, 12x12, Skin-on wedges, Crinkle cut, Pommes Parisiennes

- Optional optical sorter allows automated inspection