Controlled injection system for bone-in or boneless meats

Achieve uniform brine distribution and superior moisture retention in meat processing with an advanced injection system designed for high-speed operations.

Injects and Filters for Optimal Moisture Retention

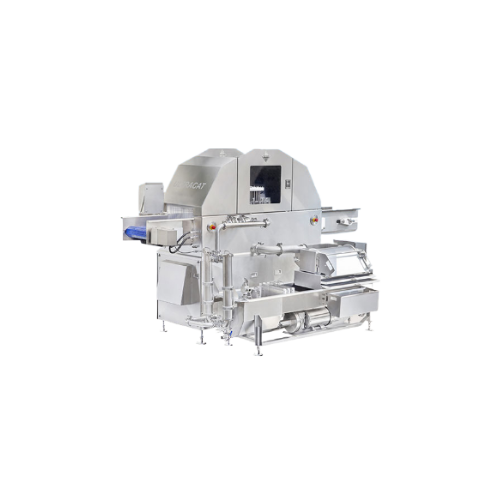

The MEPSCO UltraCAT Junior Injector offers a precision solution for poultry, meat, seafood, and ready meal processors, designed to inject brine into bone-in or boneless meats with superior uniformity. Manufactured by JBT, this injector features a versatile needle configuration with options of up to 280 special alloy stainless steel needles, allowing it to process a wide range of products including marinated beef steaks and stuffed chicken breasts. With an operation capacity of up to 12,000 pounds per hour, it ensures high-speed, continuous processing suitable for demanding production lines.

The UltraCAT Junior integrates seamlessly into existing systems, equipped with a self-cleaning rotating drum filter and dual pressure filters that remove up to 95% of solids, thus maintaining consistent injection quality. Automation is enhanced through a programmable touch screen, enabling easy adjustments for different products and profiles. The injector’s energy efficiency is supported by a 25 hp motor, reducing operational costs.

Constructed with easy-to-clean stainless steel surfaces, it caters to rigorous hygiene and maintenance standards, supporting the enhanced food safety requirements of processors. Optional features include tenderizer needles and a configurable brine flow system, providing customization potential suited to varying processing needs.

Benefits

- Ensures precise and uniform brine distribution, enhancing product flavor and texture consistency.

- Reduces operational costs with energy-efficient motor and high-capacity throughput.

- Minimizes downtime due to easy-to-clean design and advanced self-cleaning filtration system.

- Supports a wide range of products with customizable needle configurations and brine flow options.

- Enhances food safety through stainless steel construction and robust filtration processes.

- Applications

- Seafood, Meat, Ready meals, Poultry

- End products

- Chicken breast fillets, Smoked salmon portions, Barbecue ribs, Breaded fish fillets, Stuffed chicken breasts, Marinated beef steaks

- Steps before

- Grinding, Marination, Brine Preparation

- Steps after

- Cooking, Frying, X-Ray Inspection, Packing, Sterilization

- Input ingredients

- bone-in meat, boneless meat, brine

- Output ingredients

- injected meat, moisture-retained meat

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Needle configuration

- 210 or 280 needles

- Production rate

- Up to 12, 000 pounds per hour

- Needle size

- .118” (3 mm), .158” (4 mm), .188” (5 mm)

- Injector speed

- Up to 55 strokes/minute

- Injection range

- Up to 85%

- Brine holding tank capacity

- 60 gallons

- Brine filter stages

- 5-stage

- Power requirement

- 25 hp at 460V (35 amp), 3-phase, 60Hz

- Air pressure

- 80 PSI

- Brine connection

- 1½”

- Injection control

- Programmable touch screen

- Needle configuration

- 210, or 280 needles

- Injection speed

- Up to 55 strokes/minute

- Moisture retention

- Best in class

- Filtration system

- Self-cleaning rotating drum filter

- Solids elimination

- 95% of solids eliminated

- Injection range

- Up to 85% from a single pass

- Cleanability

- Stainless steel surfaces

- Corrosive resistance (e.g. acids)

- Special alloy stainless steel

- Density/particle size

- Up to 280 needles

- Needle configuration

- 210 or 280 needles

- Needle material

- Special alloy stainless steel

- Needle sizes

- .118” (3 mm), .158” (4 mm), .188” (5 mm)

- Brine valve option

- 1-way (down) or 2-way full flow (up, down)

- Brine holding tank capacity

- 60 gallons

- Filtration system

- 5-stage brine filter, self-cleaning drum filter

- Needle manifold

- Quick change

- Footprint

- Compact

- Control panel type

- Programmable touch screen

- Needle configuration

- 210 or 280 needles

- Needle type

- Special alloy stainless steel or tenderizer needles

- Flow control

- 1-way (down) or 2-way full flow (up, down) brine valve

- Brine holding tank size

- 60-gallon

- Injector speed

- Fully adjustable up to 55 strokes/minute

- Injection range

- Up to 85% from a single pass

- Filtration system

- 5-stage with self cleaning rotating drum filter

- Brine connection

- 1½”