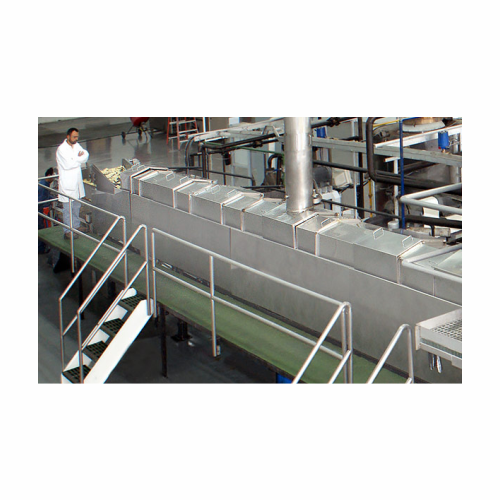

Universal fryer system for snack foods

Optimize your snack production with customizable frying modules that allow precise control over recipe, texture, and color, ensuring consistent quality and efficient oil management for a diverse range of crispy treats.

Frys and Filters Diverse Snack Varieties

The Universal Product Cooker from Heat and Control revolutionizes snack food production with its modular fryer system. Tailored for snack and chip manufacturers, it excels in efficiently frying various products from potato chips to multi-grain snacks. The cooker utilizes independent fryer modules, enabling control of time, temperature, and oil flow to customize recipes precisely. This versatile system processes multiple snack types, including kettle-cooked and plantain chips, without requiring slice washing, thanks to its continuous oil filtration and efficient heat exchangers. With a user-friendly Programmable Logic Control (PLC) system, multiple recipes can be programmed for quick product changes, enhancing production flexibility. The cooker integrates seamlessly with existing production lines, offers energy-efficient operation, and complies with industry standards, making it a valuable asset in modern snack manufacturing.

Benefits

- Reduces operational costs with integrated, modular frying system.

- Enhances product quality with continuous oil filtration, extending shelf life.

- Increases production flexibility with PLC-stored recipe management for quick transitions.

- Optimizes energy use, lowering consumption through temperature and flow control.

- Seamlessly integrates with existing production lines for efficient snack manufacturing.

- Applications

- Extruded snacks, Malanga root chips, Plantain chips, Snacks, Pellet snacks, Tortilla chips, Potato chips, Multi-grain chips, Corn chips, Kettle potato chips

- End products

- Kettle-cooked chips, Fried plantain slices, Taro chips, Puffed cheese snacks, Potato crisps, Puffed snacks, Multi-grain crisps, Nacho chips, Tortilla crisps

- Steps before

- Cutting, Peeling / Grading, Corn Cooking, Soaking, Conveying, Conditioning

- Steps after

- Seasoning, Packaging, Cooling, Inspection

- Input ingredients

- potato slices, kettle-style chips ingredients, plantain chips ingredients, malanga root chips ingredients, snack food ingredients, pellet snacks base, corn for tortilla chips, extruded snacks base, multi-grain chip ingredients

- Output ingredients

- traditional potato chips, hard-bite kettle style chips, plantain chips, malanga root chips, various snack foods, pellet snacks, corn chips, tortilla chips, extruded snacks, multi-grain chips

- Market info

- Heat and Control is known for its expertise in manufacturing food processing and packaging equipment, providing innovative solutions and high-quality systems for industries like snacks, prepared foods, and pharmaceuticals, with a strong reputation for reliability and technical support.

- Automation

- Programmable Logic Controls (PLC)

- Capacity

- Varies (Adjustable) for different chip types

- Continuous filtration

- In each frying module

- Oil flow adjustment

- Adjustable for customized recipes

- Recipe change time

- Minutes

- Type of fryer

- Kettle and traditional

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- PLC Controls

- Changeover time

- Change products in minutes

- CIP/SIP

- Continuous filtration

- Cooking oil quality

- Continuously filtered

- Recipe customization

- Adjust time, temperature, and oil flow

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- Programmable Logic Controls (PLC)