Semi-automatic frozen french fries production line

Improve efficiency in your production line with a semi-automatic system designed to streamline the complex process of producing high-quality frozen fries from root vegetables, ensuring precision and consistency in every batch.

Processes and Packages Frozen and Snack Foods

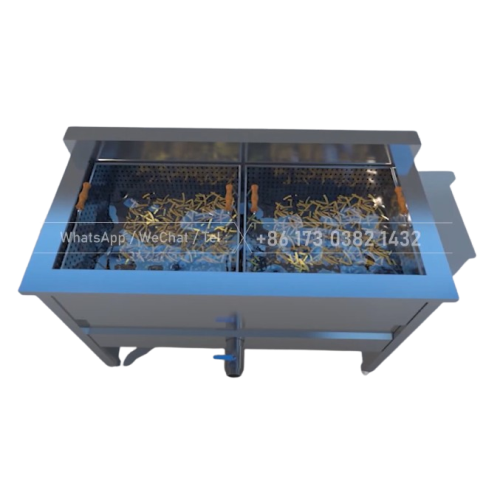

The Semi-Automatic Frozen French Fries Production Line from Taizy Machinery is tailored for small and medium-sized food manufacturers seeking efficient production solutions for snack foods like frozen French fries and root vegetable chips. By integrating a series of specialized equipment—cleaning and peeling machines, cutting machines, blanching machines, and more—this line ensures streamlined processing from raw tuber crops to packaged products. With a processing capacity ranging from 50kg to 500kg per hour, it effectively meets varying production demands. The system’s design prioritizes energy efficiency and labor saving, featuring automation in critical steps like frying and packaging, reducing energy consumption by controlling oil temperatures precisely. Constructed from stainless steel, it ensures durability and compliance with food safety standards, offering easy cleaning and minimal maintenance through its modular setup. Customization options are available to tailor the line to specific operational needs, supported by Taizy’s engineering expertise.

Benefits

- Enhances production efficiency by integrating all essential processes from washing to packaging.

- Reduces labor costs through its semi-automatic operation, minimizing manual intervention.

- Ensures consistent product quality with precise control over frying and packaging conditions.

- Lowers energy expenses with optimized motor control and heat management.

- Offers versatility across a range of tuber crops, expanding your product lineup with minimal reconfiguration.

- Applications

- Sweet potatoes, Beets, Snack foods, Tuber crops, Onions, Potato chips, Frozen french fries, Root vegetables, Carrots

- End products

- Sweet potato fries, Tuber crop snacks, Carrot sticks, Beet chips, Root vegetable chips, Onion rings

- Steps before

- Cleaning, Washing, Peeling, Slicing, Cutting, Blanching, Dewatering

- Steps after

- De-oiling, Flavoring, Packaging

- Input ingredients

- potatoes, carrots, onions, beets, sweet potatoes, radish

- Output ingredients

- frozen french fries, potato chips, crispy fries, tender chips

- Market info

- Taizy Food Machinery is known for manufacturing industrial food processing equipment, specializing in engineered-to-order (ETO) machinery. They have a reputation for innovative, high-quality solutions tailored to meet various customer specifications globally.

- Capacity

- 50–500 kg/h

- Automation

- Semi-automatic

- Dewatering method

- Centrifugal

- Frying method

- Oil layer heating

- Heating method

- Electric / Gas

- Packaging type

- Vacuum packaging

- Operation

- Easy and smooth

- Efficiency

- High

- Cleaning/Peeling

- Brush method

- Automation level

- Semi-automatic

- Integrated steps

- Cleaning, peeling, slicing, blanching, dewatering, frying, de-oiling, flavoring, packaging

- Batch vs. continuous operation

- Batch

- CIP/SIP

- Manual cleaning

- Energy efficiency

- Energy-efficient design

- Abrasion resistance

- High

- Biological compatibility

- Food-grade materials

- Cleanability

- Easy to clean / CIP

- Corrosive resistance (e.g. acids)

- Resistant to acidic and alkaline

- Density/particle size

- Suitable for tuber crops and root vegetables

- Suitable for

- Root vegetables

- Machine footprint

- Compact design

- Discharge method

- Automatic

- Control panel type

- Touchscreen PLC

- Compact footprint

- Space-saving

- Control panel type

- Touchscreen/HMI

- Heating method

- Electric / Gas

- Output capacity

- 50–500 kg/h

- Packaging type

- Oxygen/Nitrogen filled

- Integration possibilities

- Modular design