Laboratory ploughshare mixer for small-scale production

Achieve precise mixing and granulation for R&D and small-batch production with this versatile laboratory mixer, ideal for creating high-quality powders, granules, and coatings across multiple product types.

Mixes, Granulates, and Coats Small-Scale Batches

The Lödige Laboratory Ploughshare Mixer, available in models L5, L10, L20, and L50, is designed to fulfill precise research and development tasks across a spectrum of industries, including pharmaceuticals, food, and cosmetics. This mixer operates on a mechanically generated fluid bed principle, utilizing specialized ploughshare shovels that ensure intensive mixing dynamics, perfectly adapting to bulk solids and pumpable products. Key capabilities include efficient granulation and uniform coating processes, facilitated by adjustable mixing speeds and the inclusion of ancillary choppers for enhanced particle dispersion.

Applications span from developing drywall compounds and epoxy resins to crafting organic mascara and lactose-free protein shakes. Its capacity varies with model size, accommodating batch operations that allow for rapid prototyping and testing. The mixer is engineered for seamless integration, utilizing PLC-based controls and offering customization in drum sizes and mixing elements, which cater to diverse formulation needs. Constructed with stainless steel and compliant with GAMP5, it also incorporates options for heating and dust-free feeding to optimize processing conditions. Cleaning is simplified with easy access to components, ensuring compliance with sanitary standards and minimal downtime.

Benefits

- Achieves high-quality uniform mixing and granulation, enhancing product consistency.

- Increases process flexibility with adjustable speeds and interchangeable drums.

- Reduces development time through rapid batch processing in R&D applications.

- Minimizes product waste and contamination risk with near-complete discharge design.

- Ensures compliance with FDA and sanitary standards, crucial for sensitive formulations.

- Applications

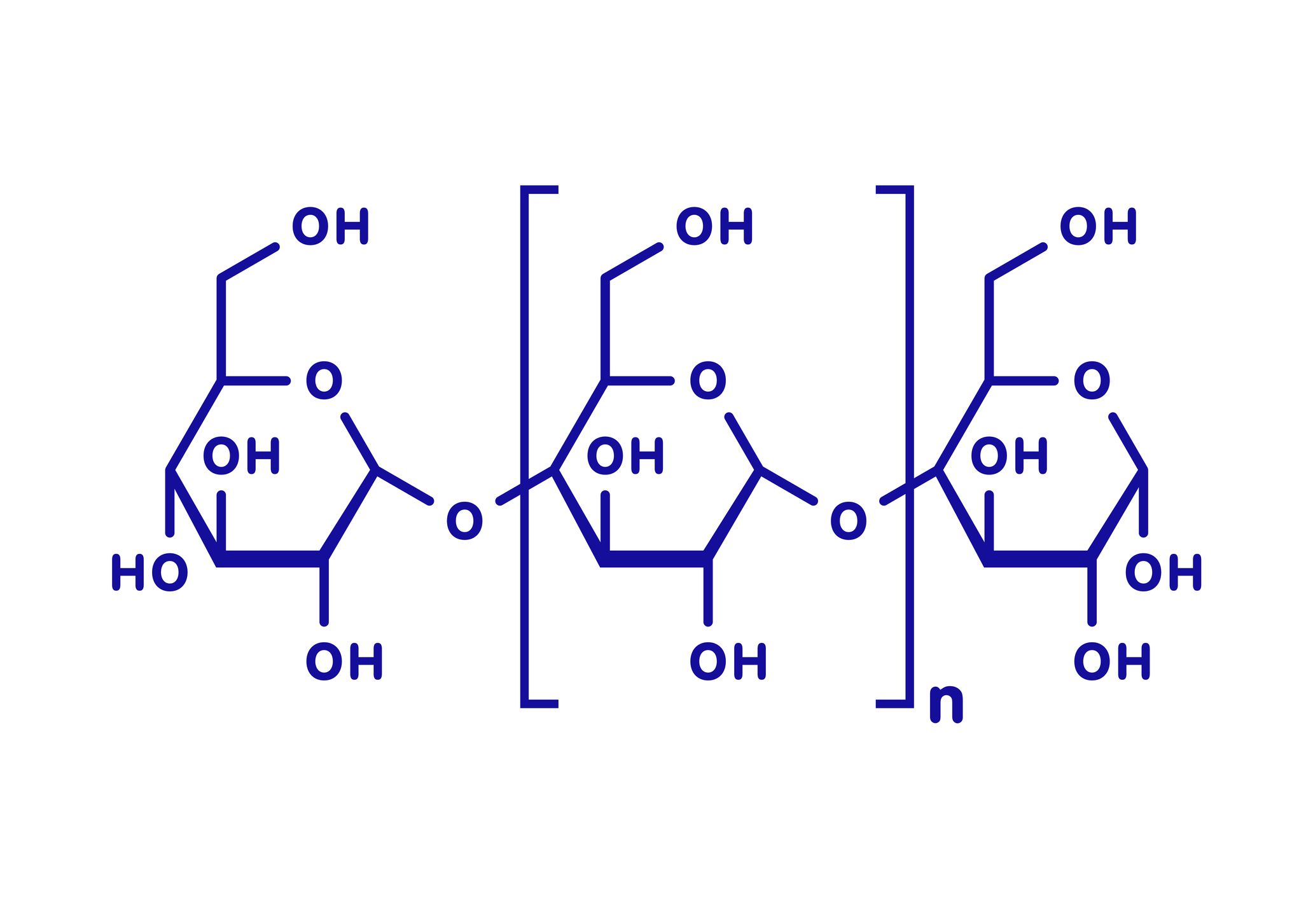

- Flavourings, Effervescent powders, Cosmetics, Baking aids, Chemicals, Food, Polysaccharides, Fruit teas, Metallurgy, Tablet compounds, Spices, Batteries, Soft cheeses, Candy, Building materials, Granola, Plastics, Pharmaceuticals, Dry soups, Coating materials

- End products

- Gluten-free cake mixes, Lithium-ion battery electrodes, Organic granola clusters, Herbal fruit infusion sachets, Foundation creams, Lactose-free protein shakes, Starch-based films, French vanilla flavoring, Instant noodle flavor packets, Cumin powder packets, Calcium tablet powder blends, Artisan bread improvers, Epoxy resins, Organic mascara, Ascorbic acid effervescent tablets, Brie cheese spreads, Sugar tablet coating, Polypropylene blends, Milk caramels, Steel alloy powders, Drywall compounds

- Steps before

- Drying, Grinding, Emulsification

- Steps after

- Granulation, Coating, Drying, Cooling, Packing

- Input ingredients

- bulk solids, powdery materials, grainy materials, fibrous materials, pumpable products, liquids, binding agents, molten fats

- Output ingredients

- fully mixed products, granulated products, coated particles, homogeneous mixtures, lump-free mixtures, tablet compounds, sugar coated tablets, capsules, pellets, compact particles

- Market info

- Loedige Process Technology is renowned for its expertise in industrial mixing, granulation, drying, and coating technologies, offering engineered-to-order solutions for various industries, including pharmaceuticals, chemicals, and food processing.

- Drum Volume

- 5, 10, 20, or 50 litres

- Mixing Principle

- Mechanical Fluid Bed

- Mixing Element Speed

- Continuously Adjustable

- Control System

- Integrated Control Unit

- Material

- Stainless Steel

- Mounting for Mixing Drum Sizes

- 5, 10, 20 l (Exchangeable)

- Liquid Addition System

- Pipe Feeds/Nozzles

- Choppers

- Optional Installation

- Heating/Cooling

- Jacket Optional

- Discharge Method

- Outlet

- Application Type

- Bulk Solids and Pumpable Products

- Particle Separation

- Mechanical Fluid Bed

- Material Compatibility

- FDA Approved

- Working mechanism

- Mechanical fluid bed

- Batch vs. continuous operation

- Batch

- Mixing element speed adjustment

- Continuously adjustable

- Liquid addition capability

- Pipes and nozzles

- Granulation capability

- Liquid addition with choppers

- Coating capability

- Molten fat, liquid nitrogen, CO₂

- Changeover options

- Exchangeable drums

- Fluid bed generation

- Mechanical

- Cleaning method

- Easy to clean design

- Particle dispersion

- Via choppers

- Control system type

- User-friendly integrated control

- Access to technical systems area

- Movable housing for 50 L mixers

- Abrasion resistance

- High durability materials

- Biological compatibility

- FDA approved materials

- Cleanability

- Easy to clean, no "dead zones"

- Corrosive resistance (e.g. acids)

- Stainless steel resistant to acids

- Density/particle size

- 0.5–2.5 g/cm³

- Chopper installation

- Optional

- Machine footprint

- Compact

- Drum size

- 5, 10, 20, or 50 litres

- Discharge method

- Outlet

- Control panel type

- Integrated in the housing

- Exchangeable drum sizes

- 5, 10, 20 l (not for 50 l)

- Cover with nozzle

- Optional

- Jacket for heating and cooling

- Optional

- Swivelling endplate

- Standard

- Mixing element speed

- Continuously adjustable

- Control panel type

- User-friendly control system

- Exchangeable mixing drum sizes

- 5, 10, 20, 50 litres

- Mixing element speed adjustment

- Continuously adjustable

- Jacket for heating and cooling

- Optional

- Chopper

- Additional installation possible

- Cover with nozzle

- Optional