Grain screening for small to midsize operations

Streamline your grain processing with an economical screening solution that ensures cleaner, dust-free grains and meets high sanitation standards, optimizing efficiency for small to midsize operations.

Screens and Cleans Grains and Spices Efficiently

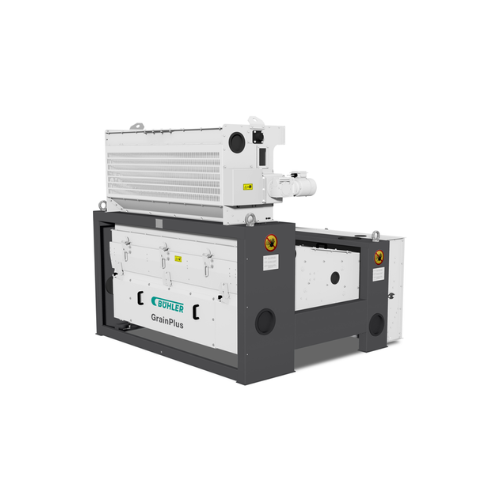

The GrainPlus Screening Machine LAGA by Bühler streamlines the cleaning and sieving processes for grains, malts, rice, pulses, and spices, ensuring high sanitation standards. Featuring a compact design, it integrates easily into new or existing facilities. The machine employs a free-running sieve box mounted on polyamide rods to minimize vibrations and prolong equipment lifespan. Its applications extend across various industries, including food processing, animal feed, and brewing, producing end-products like barley malt and whole wheat flour.

With throughput efficiency suitable for small to midsize collection points, mills, and breweries, the GrainPlus allows for optional configurations such as inlet aspiration and permanent magnets, enhancing its cleaning capabilities. The maintenance-friendly design includes a rubber ball cleaning system and a front maintenance flap for easy access. Its robust design and flexible screen options make it an ideal choice for continuous operations, offering economical solutions with minimal energy consumption.

Benefits

- Ensures high product quality by effectively removing dust and impurities.

- Integrates seamlessly into existing setups with its compact footprint.

- Reduces maintenance time with easy-access cleaning features.

- Minimizes operational disruptions with reduced vibration and longer lifespan.

- Enhances cleaning efficiency with customizable inlet aspiration and magnet options.

- Applications

- Wheat, Pulses, Paddy, Grain, Malt, Spices, Rice

- End products

- Jasmine rice, Barley malt, Quinoa flakes, Cumin powder, Whole wheat flour, Lentil flour, Basmati rice

- Steps before

- Raw material handling, Cleaning, Dehulling, Pre-screening

- Steps after

- Sorting, Sifting, Grading, Packing, Pelleting, Weighing, Dosing

- Input ingredients

- grain, malt

- Output ingredients

- cleaned grain, cleaned malt

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Capacity

- Small throughputs

- Automation

- Manual / Configurable options

- Cleaning method

- Rubber ball cleaning system

- Footprint

- Compact

- Vibration Control

- Mounted on polyamide rods

- Screening Options

- Various screen perforations

- Magnetic Separation

- Optional permanent magnet

- Aspiration

- Optional inlet aspiration

- Cleaning method

- Manual / Rubber ball cleaning system

- Batch vs. continuous operation

- Continuous

- Automation level

- Manual / PLC optional

- Changeover time

- Quick sieve changeover

- Energy efficiency

- Compact and efficient design

- Compact footprint

- Yes

- Footprint

- Small

- Discharge method

- Sieving

- Machine dimensions

- N/A

- Sieve depth

- 0.75 m

- Sieve changeover

- Quick-change

- Machine design

- Enclosed

- Mounting

- Polyamide rods

- Vibration control

- Reduced

- Inlet aspiration

- Optional

- Permanent magnet

- Optional

- Dedusting system

- Optional

- Screen perforations

- Wide range