Pulse huller for high throughput applications

Efficiently hull a wide variety of pulses and spices to enhance product quality and reduce waste, ensuring uniform consistency and high throughput, making it ideal for processors seeking to optimize yields and maintain continuous operations.

Efficiently Hulls and Processes Pulses and Spices

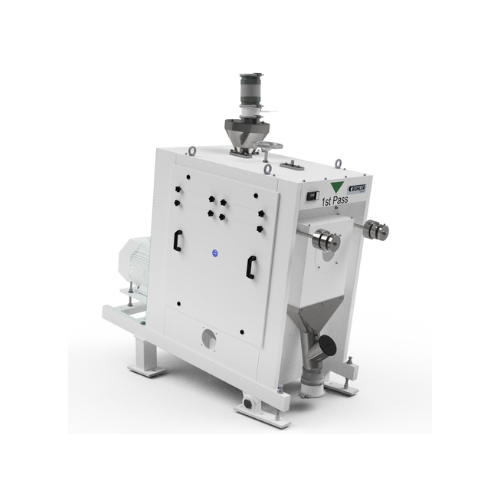

The Pulsroll Huller DRHG from Bühler is a state-of-the-art machine for efficiently hulling and processing pulses such as chickpeas, lentils, and beans. Utilizing an adjustable grinding gap and configurable emery stones, it offers precise control over the hulling process, enhancing both yield and consistency. Ideal for food processing companies and milling operations, the Pulsroll handles up to 4 tons per hour, making it suitable for high-speed, continuous operations. Its robust design ensures longevity, minimal maintenance, and low operational costs. The machine is engineered to comply with global safety standards and supports efficient cleaning and quick product changes, enhancing operational uptime. Customizable settings allow for process flexibility, accommodating various pulse shapes and sizes, and optimizing throughput to meet specific production needs.

Benefits

- Increases yield consistency with adjustable emery stones and sieve systems.

- Enhances product quality by minimizing breakage with precise milling pressure adjustments.

- Operates continuously with high throughput, processing up to 4 tons per hour.

- Reduces maintenance costs through robust design and durable wear parts.

- Supports versatile processing for various pulse and spice types with customizable machine configurations.

- Applications

- Pulses, Lentils, Beans, Spices, Peas

- End products

- Red kidney beans, Split peas, Red lentils, Pigeon peas, Chickpeas, Black beans, Green peas, Yellow lentils

- Steps before

- Cleaning, Sieving, Grading

- Steps after

- Sorting, Packing, Sifting

- Input ingredients

- beans, lentils, peas, pulses

- Output ingredients

- hulled beans, hulled lentils, hulled peas, hulled pulses

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Hulling capacity

- up to 4 tons/hour

- Power Supply

- Various motor sizes ranging between 11 kW and 18 kW

- Emery stone resistance

- up to 10, 000 tons of product

- Grinding gap adjustability

- Adjustable

- Hulling surface size

- Large

- Adjustable sieves

- Yes

- Machine inclination adjustability

- Adjustable

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Flexibility in hulling

- Adjustable for different pulse types

- High throughput

- Up to 4 tons per hour

- Robustness

- Maximized uptime and low maintenance

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Pulse type

- Beans / Lentils / Peas

- Grinding Gap Adjustment

- Adjustable

- Emery Stone Grits

- Multiple Options

- Sieves

- Interchangeable

- Machine Inclination

- Adjustable

- Motor Size

- 11 kW to 18 kW

- Sieve System

- Optional Interchangeable

- Outlet Counterweights

- Adjustable

- Hulling Pressure

- Adjustable