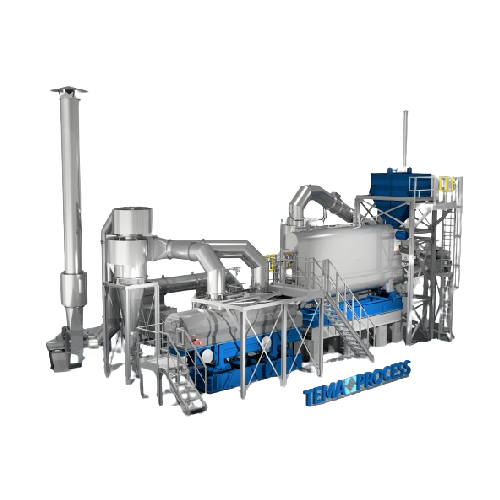

Vibrating fluid bed dryer for bulk materials

Ensure efficient moisture removal and thermal processing with this fluid bed dryer, offering precise control for diverse bulk materials, enhancing product consistency and quality in continuous or batch operations.

Dries and Fluidizes Powders and Granules Efficiently

The Shaking Fluid Bed Dryer from TEMA Process is engineered to handle versatile drying needs across minerals, food products, chemicals, and more. Utilizing a gentle shaking motion for enhanced fluidization, it processes powders and granules with precision, supporting continuous and batch operation for optimal throughput. With drying capacities up to 750 °C for gas and 400 °C for products, it efficiently dries and fluidizes materials like quartz sand, gypsum plaster, and fish meal, maintaining quality and consistency. The system is PLC-controlled for seamless integration into production lines and offers energy efficiency through optimized airflow dynamics. Constructed with durable material options for corrosion resistance, it meets rigorous industry standards, and its design includes options for customization and engineering support, ensuring it aligns with specific operational demands. Maintenance is straightforward with accessible components, minimizing downtime and maximizing productivity.

Benefits

- Enhances product consistency and quality through precise moisture control.

- Lowers operational energy costs with optimized airflow dynamics.

- Seamlessly integrates into existing production lines with PLC-controlled automation.

- Minimizes wear and prolongs lifespan with corrosion-resistant material options.

- Adapts to specific processing needs with customizable configurations.

- Applications

- Chemicals, Polymers, Animal feed, Pharmaceuticals, Organic fertilizers, Detergents, Salts, Herbs, Spices, Plastics, Food products, Minerals, Biomass, Fertilizers, Metal ores

- End products

- Metal salts, Eps beads, Phosphate fertilizers, Gypsum plaster, Refuse-derived fuel, Sodium sulfate, Potassium sulfate, Mineral ores concentrate, Herb flakes, Potash fertilizer, Biomass pellets, Fish meal, Milk powder, Pvc pellets, Chicken manure pellets, Quartz sand, Breadcrumbs, Lactose powder, Granular detergents, Sodium chloride (table salt)

- Steps before

- Purification, Grinding, Crushing, Mixing, Blending

- Steps after

- Sterilization, Pasteurization, Packaging, Roasting, Cooling

- Input ingredients

- powder, granules, wet product, minerals, chemicals, food, feed, biomass, pelletized materials, extruded materials, crystalline products

- Output ingredients

- dried powder, dried granules, thermally treated product, dried minerals, dried chemicals, dried food, dried feed, dried biomass, dried and cooled materials, roasted product, torrefied product, puffed product, blanched product

- Market info

- TEMA Process is renowned for its expertise in designing and manufacturing industrial drying solutions, specifically fluid bed dryers and coolers, powder processing equipment, and waste material recycling technologies, recognized for efficiency and innovative technologies across various industries.

- Fluidizing Velocity

- Varies based on product characteristics

- Drying Gas Temperature

- Up to 750 °C

- Product Temperature

- Up to 400 °C

- Air Speed

- Customizable

- Shaking Frequency

- Adjustable

- Energy Input

- From fluidizing air and heat exchangers

- Drying Time

- Based on product and design

- Automation

- PLC-controlled

- Submerged Heat Exchangers

- Available

- Working mechanism

- Fluidization

- Continuous vs. batch operation

- Continuous

- Automation level

- PLC / SCADA

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Product handling

- Shaking or Static

- Temperature control

- Variable up to 750 °C

- Drying integration

- Integrated Systems

- Flexible settings

- Air speed, frequency, temperature

- Fluidization dynamics

- Pressure drop and velocity control

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Varies by model

- Discharge method

- Continuous or batch

- Control panel type

- PLC

- Compact footprint

- Customizable

- Core Design

- Fluidized bed

- Customization options

- Static or dynamic configurations

- Construction materials

- Stainless Steel

- Submerged Heat Exchangers

- Optional

- Hood design

- Wide, for velocity reduction

- Control panel type

- HMI / PLC

- Integration possibilities

- SCADA / MES

- Temperature settings

- Customizable

- Air speed and flow settings

- Adjustable

- Shaking frequency

- Variable

- Material-specific adaptations

- Product size, density, and heat considerations

- Heat exchanger options

- Submerged / Non-submerged