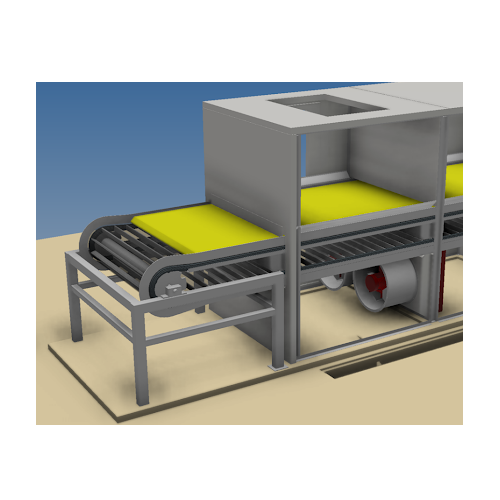

Belt dryer for large-scale continuous drying

Achieve precise moisture control and energy-efficient processing with this belt dryer, designed for continuously drying large volumes of sensitive or bulk materials with customizable thermal zones, ensuring uniform drying and optimal product quality in demanding industrial environments.

Dries and Cools Solid and Granular Products

The Belt Dryers and Coolers by TEMA Process deliver precise thermal control for various industries seeking efficient moisture management in granular and solid products. Specializing in gentle thermal treatment, these systems are divided into multiple drying zones, allowing adjustable air volumes and temperature for maximal efficiency. They are ideal for processing products such as gypsum board, milk powder, biomass pellets, and more. Capable of continuous operation, these dryers ensure consistent throughput while minimizing energy consumption, thanks to their use of low-temperature heating media.

Integration is seamless with upstream and downstream processes, equipped with PLC control for automation and optional remote monitoring. Constructed with stainless steel for hygienic and corrosion-resistant applications, they align with stringent industry standards. Designed for easy cleaning, they are equipped with modular components for simplified installation and maintenance. Each unit can be customized based on product-specific requirements, ensuring optimal drying conditions for a wide range of operational needs.

Benefits

- Enhances product quality with uniform drying and cooling processes.

- Reduces energy costs through efficient, low-temperature heating methods.

- Minimizes installation time with preassembled modular components.

- Supports hygienic operations with easy-to-clean, corrosion-resistant stainless steel design.

- Increases operational flexibility with customizable drying zones and airflow controls.

- Applications

- Chemicals, Food, Grains, Feed, Pharmaceuticals, Herbs, Spices, Plastics, Minerals, Biomass, Fertilizers, Fibres, Salts

- End products

- Sodium chloride, Detergent powders, Gelatin sheets, Eps beads, Phosphate fertilizers, Citrus pulp pellets, Spices powders, Pvc granules, Refuse-derived fuel, Animal feed pellets, Limestone powder, Biomass pellets, Feather meal, Fish meal, Gypsum board, Plastic pellets, Kaolin clay, Potassium sulphate, Organic fertilizer granules, Milk powder, Sand, Dextrose powder, Fiber fillers, Table salt, Carbon black granules, Tomato powder, Sea salt, Dried herbs, Herbal supplements, Breadcrumbs, Ammonium sulphate, Metal salts

- Steps before

- Purification, Grinding, Emulsification

- Steps after

- Cooling, Sterilization, Packing, Blanching

- Input ingredients

- wet product, high moisture load materials, temperature sensitive products, brittle products, sand, salt, quartz sand, gypsum, slag sand, limestone, kaolin, clay, chalk, potash, salts, phosphates, zeolites, coal, mineral ores, breadcrumbs, dextrose, rice, sugar, herbs, spices, flaked cereals, extruded cereals, milk powder, lactose, tomato pulp, citrus pulp, fish meal, fish feed, animal feed, return bread, sodium chloride, herbicides, CMC, detergents, ammonium sulphate, sodium sulphate, potassium sulphate, polymers, PVC, PVDC, plastics, EPS, fibres, metal salts, organic fertilizer, orange peel, lemon peel, sludge, manure, paper sludge, wood, biomass, refuse-derived fuel, carbon black granules, chicken manure

- Output ingredients

- dried product, cooled product, uniformly dried products, temperature stabilized products

- Market info

- TEMA Process is renowned for its expertise in designing and manufacturing industrial drying solutions, specifically fluid bed dryers and coolers, powder processing equipment, and waste material recycling technologies, recognized for efficiency and innovative technologies across various industries.

- Drying Zones

- Multiple with adjustable air volumes

- Temperature Control

- Adjustable within zones

- Humidity Control

- Adjustable within zones

- Airflow Control

- Downstream or upstream

- Heating Media

- Hot water, heat pump, steam, gas, thermal oil

- Material Execution

- Fully stainless steel

- Automation

- PLC-controlled

- Field Installation Time

- Preassembled parts for easy installation

- Working mechanism

- Continuous conveyor belt system

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC / SCADA

- Airflow control

- Customizable for maximum uniformity

- Cleaning method

- Easily cleanable, CIP potential

- Energy efficiency

- Maximized through controlled temperature and humidity

- Heating options

- Hot water, heat pump, steam, natural gas, thermal oil

- Corrosive resistance (e.g. acids)

- Stainless steel

- Cleanability

- Fully stainless steel execution for easy cleaning

- Density/particle size

- Various, as applicable to product requirements

- Ductility

- Brittle/Elastic

- Moisture Content

- High/Medium/Low

- Product Fragility

- Fragile/Durable

- Machine footprint

- Compact / Modular

- Belt length

- Customized length

- Belt width

- Customizable width

- Machine material

- Stainless steel

- Number of belts

- Single / Multiple

- Feed method

- Continuous infeed

- Discharge method

- Continuous discharge

- Height

- Variable, per design

- Cooling system

- Integrated inline cooling

- Segmented zones

- Multiple drying zones

- Control panel type

- PLC / HMI

- Belt type

- Perforated / Multiple belt system

- Air control system

- Adjustable air volume, temperature and humidity control

- Heating media

- Hot water / Heat pump / Steam / Natural gas heaters / Thermal oil

- System segments

- Single or multiple drying zones

- Airflow direction

- Downstream / Upstream / Both