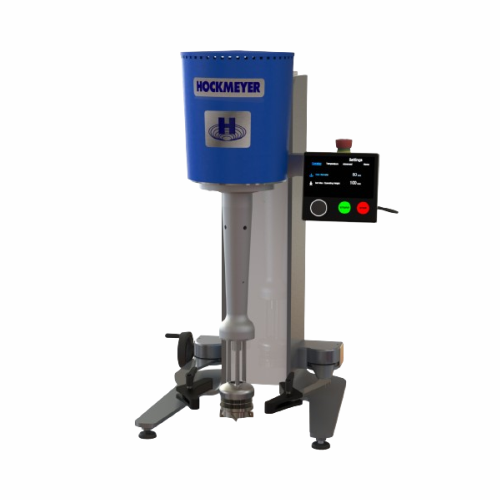

Lab-scale disperser and immersion mill

Achieve precise dispersing and milling with rapid changeover capabilities, ideal for high-precision lab environments where scalable results are crucial to optimize formulation development and pilot production processes.

Processes and Disperses Various Materials Efficiently

The MICRO MILL HM – 1/16th from Hockmeyer Equipment Corporation is a versatile laboratory-scale milling solution designed to enhance R&D productivity. This lab mill excels in dispersing, milling, mixing, and agitating a wide range of materials, from biopharmaceuticals to fine chemicals and nutraceuticals. It features disperser and immersion mill capabilities, allowing for precise control over particle size and distribution. The system operates efficiently with a batch volume of 250 mL to 2 L and integrates seamlessly into pilot and bench-top settings with automated features for ease of use. Its electronic height adjustments, speed controls, and jacketed cooling vessels ensure optimal processing conditions. The equipment supports diverse solid, liquid, and slurry end-products, including protein therapeutics, specialty chemicals, aluminum powders, and more. The MICRO MILL is particularly suited for chemical, pharmaceutical, food, and cosmetics industries, providing robust capabilities for innovation in Research & Development and Laboratory settings.

Benefits

- Enhances lab productivity with quick material change-overs and scalable results.

- Precise process control through digital display and user-friendly software, ensuring data accuracy.

- Reduces operational downtime with automated stop functions and electronic adjustments.

- Optimizes cooling efficiency with jacketed vessels, maintaining material integrity.

- Versatile application across multiple industries, supporting diverse product development.

- Applications

- Metal powders, Liquid formulations, Fine chemicals, Detergents, Nutraceuticals, Biopharmaceuticals, Spices, Coating materials

- End products

- Specialty chemicals, Herbal supplements, Paint coatings, Laundry detergents, Emulsions, Aluminum powders, Protein therapeutics, Curry powder

- Steps before

- Mixing, Pre-dispersing

- Steps after

- Testing, Cooling, Data Gathering

- Input ingredients

- materials, media

- Output ingredients

- dispersed materials, milled materials, processed materials

- Market info

- Hockmeyer Equipment is known for manufacturing high-quality industrial mixing and dispersion equipment. They specialize in ETO solutions for industries like paints, inks, and chemicals, renowned for innovation, reliability, and superior engineering.

- Volume Capacity

- 250 mL – 2 L

- Media Volume

- 49 mL

- Working mechanism

- Disperser and Immersion Mill capabilities

- Batch vs. continuous operation

- Batch

- Changeover time

- Quick change-overs

- Automation level

- Automatic controls with user-friendly software

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tank size

- 250 mL – 2 L

- Jacketed cooling vessels

- Yes

- Control panel type

- Full-color digital display

- Height adjustment

- Electronic

- Integration possibilities

- Programmable auto shut-offs

- Speed control

- Adjustable with tip speed readouts

- Cooling option

- Jacketed cooling vessels