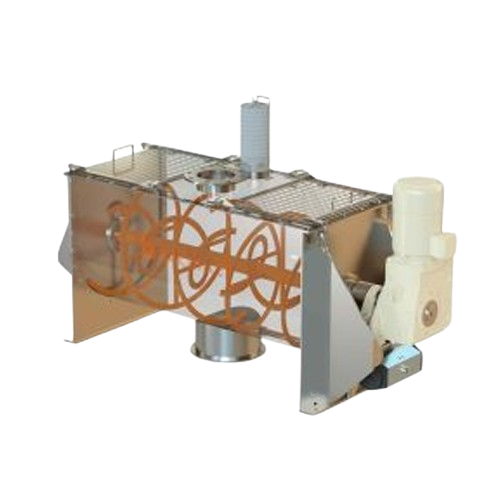

Horizontal ribbon blender for solids and powders

Efficiently achieve uniform blending of bulk solids and powders, ensuring minimal energy use and precise mixing even in large batches, making it ideal for high-throughput production environments.

Mixes and Homogenizes Solids and Powders

The Ribbon Mixer (MH) from Bachiller is engineered to efficiently mix and homogenize large batches of solids and powders, utilizing a horizontal spiral design to create inverse flows within the mixing chamber. Its suitability for processing a wide range of applications, from food additives to fine chemicals, makes it a versatile choice for industries such as pharmaceuticals, food, and chemicals. With batch capacities ranging from 200L up to 30,000L, this mixer supports scalable, repetitive operations.

Integrated features such as liquid injection by spraying and heating/cooling jackets allow for precise control over the mixing environment, enhancing process versatility. Constructed with options for internally mirror-polished surfaces to Ra ≤ 0.6 µm and ATEX-certified for explosive environments, the equipment ensures compliance with stringent industry standards.

The Ribbon Mixer (MH) is CE-marked according to Safety for Machinery Directive 2006/42/CE and is engineered for low energy consumption and reduced maintenance requirements, making it an efficient, reliable part of your production line. Its robust design can accommodate various material options to ensure chemical compatibility and longevity under demanding operational conditions.

Benefits

- Enhances mixing uniformity and consistency across diverse solid and powder formulations.

- Reduces operating costs through efficient energy consumption and low maintenance needs.

- Supports versatile processing requirements with customizable heating and cooling options.

- Ensures safety and compliance with ATEX certification for explosively sensitive environments.

- Provides scalability for large or small production batches, streamlining process integration.

- Applications

- Powder detergents, Pesticides, Plastic recycling, Minerals, Extinguisher powder, Dextrin, Chemicals, Atomized detergents, Cocoa powder, Insecticides, Feed additives, Fine chemicals, Explosives, Waste treatment, Candies, Spices, Feed, Titanium dioxide, Phosphates, Refractories, Pet food, Carbonate, Bakery ingredients, Milk powder, Soluble drinks, Special mortars, Resins, Algaecides, Food additives, Phytosanitary, Pharmaceutical preservatives, Herbicides, Soluble coffee, Food preparations

- End products

- Weed killer granules, Dishwashing powder, Infant formula, Plant growth regulator, Roundup, Ready-mix mortar, Dutch-processed cocoa, Sandblasting sand, Vaccine stabilizers, Garlic powder, Kibble, Gluten-free bread mix, Premix feed supplements, Artificial sweeteners, Chlorine tablets, Ant killer powder, Sodium carbonate, Laundry detergent granules, High-temperature bricks, Epoxy resins, Compostable waste bags, Recycled plastic pellets, Cattle feed pellets, Energy drink powder, Triple superphosphate, Gummy bears, Instant soup mix, Fertilizer prills, Corn maltodextrin, Titanium dioxide pigment, Instant coffee granules, Fire extinguisher powder

- Steps before

- Grinding, Drying

- Steps after

- Packing, Coating

- Input ingredients

- Additives, Bakery ingredients, Candies, Cocoa powder, Dextrin, Feed, Food preparations, Improvers, Milk powder, Paprika, Pastry ingredients, Pet Food, Soluble coffee, Soluble drinks, Spices, Algaecides, Atomized detergents, Carbonate, Explosives, Extinguisher powder, Herbicides, Insecticides, Lots homogenization, Minerals, Pesticides, Phosphates, Phytosanitary, Plastic recycling, Powder detergents, Refractories, Resins, Special mortars, Titanium dioxide, Waste treatment, Preservatives

- Output ingredients

- Homogenized solids, Mixed powders

- Market info

- Bachiller specializes in industrial engineered-to-order equipment, known for high-quality process equipment in the chemical, petrochemical, pharmaceutical, and food industries. They are recognized for their expertise in designing and manufacturing pressure vessels, reactors, and mixing equipment.

- Capacity

- 200L up to 50.000L

- Mixing time

- Maximum 30 minutes

- Mixing accuracy

- 1

- Batch size

- 100 to 30.000 liters

- Operation mode

- Batch-wise operation

- CE marking

- Safety for Machinery Directive 2006/42/CE

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual

- Automation level

- Manual / PLC

- Energy efficiency

- Low

- Mixing mechanism

- Horizontal spiral

- Mixing time

- up to 30 minutes

- Repetitive mixing processes

- Reproducible

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Capacity

- 100-30, 000 L

- Capacities

- 200-50, 000 L

- Mixing Spiral Type

- Horizontal

- Mixing Spiral Speed

- Moderate

- Footprint

- Compact

- Discharge Method

- Complete Discharge

- Shape

- Horizontal Chamber

- Internal Polishing

- Mirror polished Ra ≤ 0.6 µm (Grit 360)

- External Polishing

- Matte finish

- Liquid Injection

- By spraying

- Heating/Cooling Jacket

- Available

- Inspection Doors

- Automatic opening

- ATEX Executions

- Available on request

- Solids Loading and Dosing Systems

- Available

- Weighting Systems

- Available

- Formulation Installations

- Available

- Product Packing System

- Available