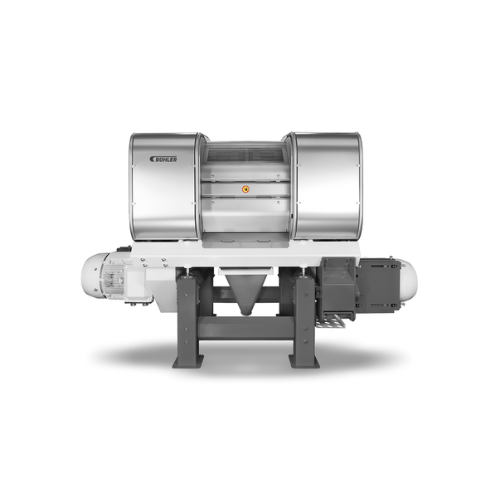

Flaking mill for grain and cereal production

Achieve consistent flake thickness and high throughput with advanced roller technology, designed to meet stringent food safety standards and streamline maintenance in your flaking operations.

Flakes, Mills, and Grinds Grains and More

The PolyFlake Flaking Mill from Bühler is engineered to deliver reliable, high-capacity flaking performance in grain and food processing. Featuring an integrated roller cooling system and automatic roller gap adjustment, it ensures precise flake consistency for applications ranging from breakfast cereals to animal feed. The mill processes a wide variety of products, including corn, oat, and multigrain flakes, with a capacity tailored to demanding production environments. Designed for continuous, automated operation, it integrates seamlessly into production lines, minimizing downtime with its accessible design and low-maintenance components. Constructed with Dibond aluminum cladding and compliant with stringent food safety standards, it supports efficient cleaning and maintenance, making it a robust solution for consistent, high-speed flaking.

Benefits

- Ensures consistent product quality with automated roller gap control.

- Increases production efficiency with high throughput and stable operation.

- Minimizes maintenance time due to accessible, hygiene-friendly design.

- Reduces operational noise and costs with durable, low-maintenance components.

- Meets stringent food safety standards with easy-to-clean construction.

- Applications

- Snacks, Grain, Cosmetics, Chocolate, Dairy, Chemicals, Printing inks, Pulses, Paddy, Spices, Aqua feed, Breakfast cereals, Batteries, Cocoa, Animal feed, Pasta, Pet food, Nuts, Rice, Paints, Electronic materials, Baked goods, Oilseeds, Wheat, Confectionery, Digital inks, Coatings

- End products

- Cereal flakes, Spice-infused flakes, Wheat flakes, Nut-flavored cereal clusters, Oilseed flakes, Grain bars, Multigrain flakes, Dairy-based cereal bars, Rice flakes, Oat flakes, Animal feed pellets, Corn flakes, Aqua feed flakes, Chocolate-coated cereals, Pasta pre-mix flakes

- Steps before

- Grain handling, Conditioning, Dehulling

- Steps after

- Sifting, grading, Packing, Pelleting

- Input ingredients

- grain, grain pellets

- Output ingredients

- corn flakes, multigrain flakes, cereal flakes, breakfast cereals, oat flakes

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Throughput

- High, optimized for corn flakes, multigrain flakes, cereal flakes, breakfast cereals, and oat flakes

- Roller Size

- Large rollers

- Roller Cooling System

- Integrated

- Roller Gap Adjustment

- Automatic

- Flake Consistency

- Consistent thickness every batch

- Noise Level

- Low-noise operation

- Maintenance

- Easy maintenance, hygiene-friendly design

- Automation

- Automated gap control and adjustment

- Covers Material

- Dibond aluminum cladding

- Construction Features

- Rounded corners, minimal horizontal surfaces

- Power Transmission

- Durable timing belt

- Stability

- High adjustment accuracy and exceptional grinding stability

- Automation level

- Automated gap control

- Batch vs. continuous operation

- Batch

- Cleaning method

- Easy access for cleaning

- Hygiene design features

- Rounded corners and minimal horizontal surfaces

- Maintenance ease

- Improved accessibility

- Product safety features

- Operator and product protection covers

- Roller gap adjustment

- Automatic

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Flake Consistency

- Consistent/Variable

- Control Panel Type

- HMI / Touchscreen

- Integration Possibilities

- SCADA / PLC

- Roller Gap Adjustment

- Automatic / Manual