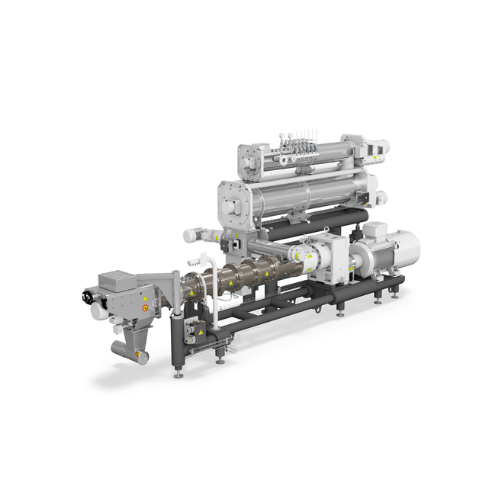

Single-screw extruder for pet food and aqua feed

For producers aiming to diversify their offerings, this single-screw extrusion solution enables precise control and adaptability, ensuring consistent product quality across a variety of food and feed applications.

Processes Diverse Food and Feed Products

The Single-Screw Extruder from Bühler Group is a versatile solution for the food and feed industry, engineered to handle diverse applications ranging from pet food and aqua feed to confectionery and alternative proteins. Its modular design allows for easy adaptation and integration into existing production lines, accommodating various processes like extrusion, mixing, and feeding. This extruder is equipped with intelligent automation systems, ensuring precise control and minimizing downtime through automated safety shutdowns. It supports continuous high-speed operations, making it suitable for manufacturing a wide range of end products such as kibble, protein bars, spaghetti, and pea protein concentrate. With features like a two-stage preconditioner for improved product quality and user-friendly touch screen controls, this extruder provides efficient production and quick recipe switching. The design prioritizes food safety and ease of maintenance, aligning with high sanitation standards and offering modular upgrades to meet specific production needs.

Benefits

- Enhances production flexibility with modular design for varied product outputs.

- Maintains high product quality through intelligent recipe memory, minimizing human error.

- Maximizes production efficiency with continuous high-speed operations and reduced downtime.

- Ensures food safety with high sanitation standards and easy maintenance accessibility.

- Adapts to specific production requirements through customizable modules and configurations.

- Applications

- Animal feed, Baked goods, Alternative proteins, Insect technology, Snacks, Pet food, Pasta, Confectionery, Pulses, Food ingredients, Spices, Aqua feed, Breakfast cereals, Dairy

- End products

- Cheese snacks, Spaghetti, Granola bars, Breadsticks, Chai spice mix, Livestock pellets, Lentil flour, Kibble, Sweet coated nuts, Fish pellets, Cricket flour, Soy protein isolate, Pea protein concentrate, Protein bars

- Steps before

- Conditioning, Preconditioning, Mixing, Dehulling

- Steps after

- Cooling, Drying, Packing, Palletizing

- Input ingredients

- pet food ingredients, aqua feed ingredients, protein sources, grains, pulses, spices, nuts, oilseeds

- Output ingredients

- extruded pet food, extruded aqua feed, processed protein products, shaped feed products

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Capacity

- Based on specifications

- Screw Speed

- Variable

- Torque

- Variable

- Pressure

- Variable

- Automation

- User-friendly touch screen control

- Modularity

- Expandable with additional modules

- Preconditioner Stages

- Two-stage

- Feeder Screw Transition

- Enforced infeed

- Cleaning

- Side access for cleaning

- Working mechanism

- Single-screw extrusion

- Automation level

- User-friendly touch screen control

- CIP/SIP

- Manual, side access cleaning

- Batch vs. continuous operation

- Continuously adjustable

- Changeover time

- Efficient with recipe memory

- Energy efficiency

- State-of-the-art process control

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Modular design

- Yes

- Control panel type

- Touch screen

- Feed/discharge method

- Vertical inlet

- Number of screws

- Single

- Material inlet position

- Vertical

- Modular design

- Adaptable for capacity and process requirements

- Recipe memory

- Intelligent system for consistent quality

- Control panel type

- Touch screen interface

- Safety features

- Automatic shutdown in emergencies

- Additional modules

- Density control, SME Module, extruder end barrel valve, hygienic cutter