Ground coffee handling and conveying system

Enhance your coffee production with precise handling systems that ensure aroma preservation and consistent homogenization, vital for maximizing quality from extraction through to packaging.

Ensures Consistent Homogenization and Precise Dosage

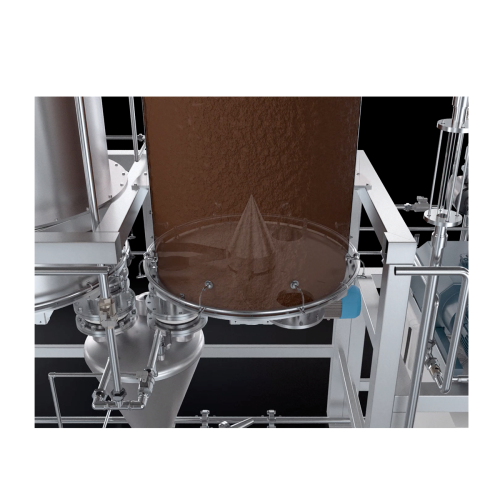

The ExtraMAX Mechanical Extractor from IMA Group addresses the critical need for homogenization and precise dosing in ground coffee processing. Utilizing a flat extraction system, it overcomes issues like demixing and agglomeration that commonly occur with vibrating systems. Applications range from espresso and Moka to filter coffee grounds, making it essential for diverse coffee blends. With engineered precision, the system supports capacities suitable for industrial coffee manufacturers, ensuring high production rates and consistent product quality. Designed for seamless integration into existing production lines, the ExtraMAX system can optimize energy consumption and maintain product integrity. It is crafted for robustness and ease of maintenance, providing long-term reliability in coffee processing operations.

Benefits

- Enhances product quality by ensuring homogenization and preventing demixing.

- Reduces energy consumption with optimized mechanical extraction processes.

- Improves operational efficiency with precise dosing capabilities.

- Minimizes product contamination through vacuum transport systems.

- Supports versatile coffee production, accommodating various coffee blends and formats.

- Applications

- Ground coffee, Spices, Roasted coffee

- End products

- Turkish coffee blend, Moka coffee grounds, Homogenized spice mix, Filter coffee grounds, Espresso coffee grounds, Pre-packaged ground coffee for capsules, Pre-packaged roasted coffee beans

- Steps before

- Roasting, Grinding

- Steps after

- Primary Packaging, Secondary Packaging, End of Line

- Input ingredients

- green coffee, raw coffee beans, whole beans

- Output ingredients

- ground coffee, homogenized coffee, capsules, packaged coffee, espresso coffee, filter coffee, Moka coffee

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Conveyor Type

- Tubular disc conveyor

- Conveyor Purpose

- Prevent demixing and oxidation

- Transport System

- Pneumatic Transport System

- Silo Extraction System

- ExtraMAX mechanical extractor

- Delivery System

- Vacuum system to avoid contamination

- Homogenization Equipment

- DuoMIX continuous homogenizer

- Controlled Atmosphere

- Air tight ground coffee systems

- Handling Capacity

- Suitable for long distances and high production rate

- Mixing Capability

- Mixing coffee and spices

- Homogenization Consistency

- Continuous and reliable mixing results

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- CIP / Manual

- Automation level

- Mechanically-controlled

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Homogenization ability

- Continuous

- Contamination prevention

- Vacuum system

- Aroma preservation

- Controlled atmosphere

- Handling method

- Tubular disc / Pneumatic Transport

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Powder handling

- Suitable for coffee and spices

- Machine footprint

- N/A

- Discharge method

- Mechanical extraction

- Control panel type

- PLC-controlled

- Compact footprint

- Yes

- Discharge method

- Flat extraction system