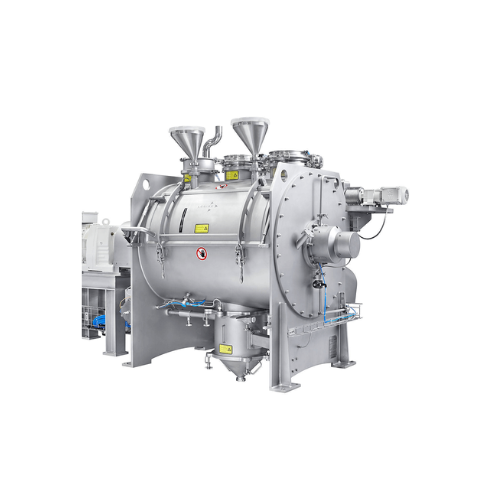

Hygienic mixer for batch operation

Achieve consistent and precise mix quality across diverse powders and granules with this high-speed batch mixer, designed for gentle product treatment and rapid processing in complex formulations.

Mixes and Granulates Diverse Materials Efficiently

The Ploughshare® Mixer from Gebrüder Lödige Maschinenbau is an engineered-to-order solution for efficient batch processing in sectors such as food, pharmaceuticals, and cosmetics. Known for its unique mixing mechanism, the Ploughshare® Mixer employs rotating mixing tools within a horizontally fitted cylindrical drum to create a three-dimensional movement of materials, resulting in precise mixing and granulation. This versatility extends to handling solids, powders, granules, and even liquids, catering to complex formulations like oven-ready flours, dietary supplements, and cosmetic compacts.

Capacities vary per model, with design optimization ensuring high throughput while minimizing dead zones through continuous material engagement. Integrated high-speed choppers further enhance the granulation process, breaking down agglomerates and distributing liquids uniformly. Customizable with heating or cooling jackets and engineered in various material grades—such as stainless steel for chemical resistance—the mixer meets industry-specific requirements including FDA approval and GAMP5 compliance. Maintenance is simplified with easy-to-clean designs and accessible components, supported by Lödige’s engineering expertise to tailor configurations—such as control systems and additional feeding methods—ensuring seamless integration into existing production lines.

Benefits

- Achieves uniform product consistency with precise, three-dimensional mixing action.

- Expands processing capabilities with adaptable mixing tools for various material types.

- Enhances operational efficiency with quick setup and reduced cleaning times.

- Provides scalable solutions for diverse industries with customizable configurations.

- Complies with industry standards for safety and hygiene, ensuring regulatory alignment.

- Applications

- Flavourings, Facial powder, Fruit drinks, Effervescent powders, Bath essences, Baking aids, Bouillon powders, Decorative sugar, Oven-ready flours, Fruit teas, Tablet compounds, Mascara, Pre-mixes for tablet compounds, Film coating, Spices, Sugar coating, Soft cheeses, Chocolate pastes, Candy, Eye shadow, Granola, Hair dye, Metal powders, Table salts, Dry soups, Raw materials for implants, Vitamin products, Cheese spread, Crispy coating, Cocoa drinks, Lipsticks

- End products

- Brie cheese, Sugar-coated lozenges, Stock cubes, Compact powder, Baking soda, Multivitamin supplements, Caramel chews, Enteric-coated tablets, Stainless steel powder, Liquid eyeliner, Cosmetics-grade titanium powder, Cinnamon sticks, Curry powder, Herbal fruit blend, Sea salt flakes, Smoothie bases, Instant noodle seasoning, Cornbread mix, Hazelnut spread, Lip balm, Tablet excipients, Sprinkles, Cheese dip, Bath bombs, Fizzy vitamin tablets, Pain relief tablets, Hair dye kits, Crunchy granola clusters, Instant hot chocolate mix, Blush palette, Panko breadcrumbs

- Steps before

- Emulsification, Grinding, Drying, Purification

- Steps after

- Granulation, Coating, Vacuum Drying, Packing, Sterilization

- Input ingredients

- powdered materials, grainy materials, fibrous materials, components with different bulk densities, liquid components, binding agents, molten fat, coating agents

- Output ingredients

- high-quality mixes, granulated products, coated particles, increased bulk density, compact particle structure

- Market info

- Loedige Process Technology is renowned for its expertise in industrial mixing, granulation, drying, and coating technologies, offering engineered-to-order solutions for various industries, including pharmaceuticals, chemicals, and food processing.

- Mixing quality

- Extremely high

- Mixing time

- Short

- Batch reproducibility

- High

- Product treatment

- Gentle

- Accessibility

- Easy

- Process

- Multi-stage

- Mixing elements

- Ploughshare® Shovels

- Drum orientation

- Horizontal

- Movement type

- Three-dimensional

- Speed variability

- Adjustable

- Additional support

- High-speed choppers

- Liquid addition

- Pipes or nozzles

- Granulation

- Adjustable particle size

- Coating method

- Molten fat/liquid nitrogen

- Construction materials

- Various, including stainless steel

- Explosion protection suitability

- Yes

- Control system

- Modern, user-friendly

- Cleaning system

- WIP

- Working mechanism

- Ploughshare® mixing technology

- Integrated steps

- Mixing, granulation, coating

- CIP/SIP

- Easy to clean, WIP systems available

- Batch vs. continuous operation

- Batch

- Cleaning method

- Easy accessibility for cleaning

- Automation level

- User-friendly control system

- Reproducibility

- High

- Product treatment

- Gentle

- Multi-stage processes

- In one machine

- Liquid addition

- Precise distribution with pipes/nozzles

- Granulation effect

- Supports systematic granulation

- Energy efficiency

- Low-maintenance

- Turbulence generation

- 3D movement of components

- Accessibility

- Easy access to internal components

- Support for special tasks

- High-speed choppers

- Abrasion resistance

- High

- Biological compatibility

- FDA approved materials

- Cleanability

- Easy to clean (Hygienic design)

- Corrosive resistance (e.g. acids)

- Stainless steel options available

- Density/particle size

- Accommodates various densities and particle sizes

- Mixing Drum Type

- Horizontally fitted, cylindrical drum

- Mixing Tool Arrangement

- Ploughshare® shovels on a shaft

- Mixing Tool Movement

- Three-dimensional movement

- Additional Devices

- High-speed choppers

- Inspection and Cleaning Access

- Large inspection door, easy accessibility

- Material Construction Options

- Structural steels, stainless steels, special materials

- Heating/Cooling Jacket

- Available for heating and cooling

- Liquid Addition System

- Pipes or nozzles for liquid addition

- Explosion Protection Suitability

- Suitable for nearly all explosion protection zones

- Control System

- Modern, user-friendly control system

- Material choice

- Structural steels to stainless steels to special materials

- Chopper devices

- Available

- Jacket

- Heating and cooling

- Addition of liquids

- Moistening + granulation

- Batch mixer with large feeding door

- For manual feeding

- Explosion protection zones

- Suitable

- Large inspection door

- Available

- Cleaning systems

- WIP (Wet In Place)

- Partial systems with feeding/draining systems

- Available

- Control system

- Modern, user-friendly