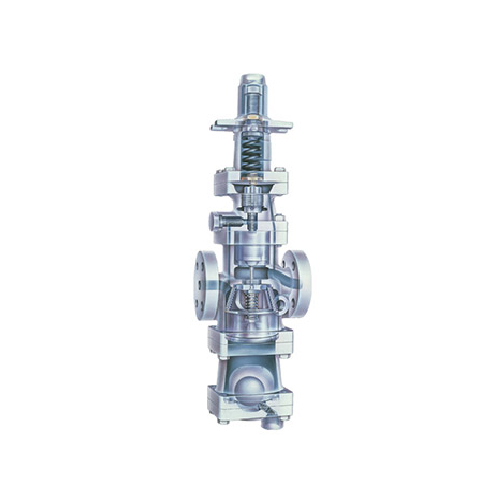

Industrial steam systems for conditioning

Efficiently deliver optimal steam conditioning for diverse feedstock, enhancing moisture control and heating precision in production lines.

Conditions and Moisturizes for Optimal Product Quality

CPM’s Steam Conditioning System offers a robust solution for industries such as animal feed and biomass processing, where precise thermal control and moisture addition are critical. The system operates by delivering low-velocity steam to ensure even heat distribution and controlled moisture content, crucial for producing consistent end products like cattle feed pellets and wood pellets. The integration of automation allows continuous high-speed operations customized to meet specific processing requirements. With energy-efficient engineering, it reduces steam consumption while maintaining optimal performance. Constructed with durable materials suitable for various applications, CPM’s steam systems can be customized to complement existing production lines seamlessly.

Benefits

- Ensures consistent product quality through precise temperature and moisture control.

- Increases processing efficiency, reducing steam usage and energy costs.

- Integrates seamlessly with existing production lines for streamlined operations.

- Customizable to meet specific industry requirements, enhancing production flexibility.

- Supports continuous automated processes, minimizing manual intervention and labor costs.

- Applications

- Aquaculture, Animal feed, Ethanol, Pet food, Hemp, Food industry, Oilseed processing, Hops, Rendering, Biomass

- End products

- Dog kibble, Wood pellets, Bone meal, Ethanol fuel, Hop pellets, Hemp oil, Fish feed pellets, Cattle feed pellets, Breakfast cereals, Soybean meal

- Steps before

- Pelleting, Weighing, Particle Size Reduction, Oilseed Preparation

- Steps after

- Pelleting, Cooling, Briquetting, Loading

- Input ingredients

- water, feed ingredients, raw meal, oilseeds, biomass

- Output ingredients

- high-quality steam, conditioned feed, moisturized meal, softened oilseeds, pre-treated biomass

- Market info

- CPM is known for manufacturing high-quality process equipment and technology solutions for the industrial and agricultural sectors, specializing in particle size reduction, conditioning, and pelleting solutions with a strong reputation for reliability and innovation.

- Automation Level

- Integrated with MM4 Automation System

- Steam Quality

- High-quality, low-velocity steam

- System Customization

- Engineered for unique conditioning requirements

- Control System

- PLC/SCADA supported

- Interoperability

- Compatible with CPM conditioners

- Steam quality

- High-quality, low-velocity

- Customization level

- Engineered-to-order

- Automation level

- MM4 Automation System

- Integrated system components

- Works together with other components

- Batch vs. continuous operation

- To be customized based on needs

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Conditioning Solutions

- Infusion Series / LTC Series

- Related Equipment

- Pellet Mills, Coolers, Pellet Crumblers

- Machine footprint

- Customizable

- Tank shape and size

- Customizable

- Feed/discharge method

- Customizable

- Control panel type

- UL508A Control Panel

- Compact footprint

- Yes

- Control panel type

- Customized HMI

- Integration possibilities

- Compatible with existing systems