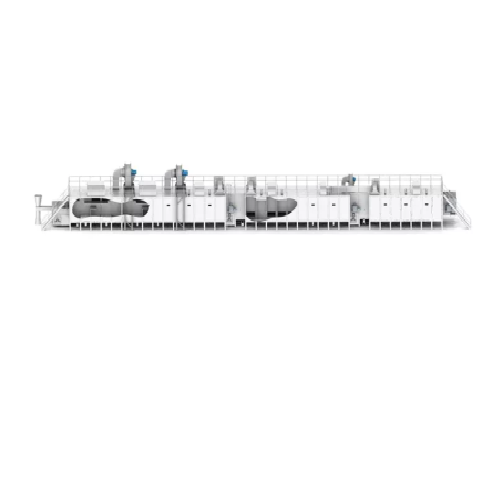

Belt dryer for food and pet food products

Optimize drying processes with customizable belt dryers, engineered to handle robust moisture removal for a variety of products from food to renewable materials, ensuring consistent product quality and improved operational efficiency in your production line.

Efficiently Dries and Handles Diverse Industrial Materials

The Belt Dryer Type BTF-S from STELA Laxhuber GmbH stands out by offering an innovative stage-based drying system tailored for industries such as agriculture, food processing, and renewable fuels. This dryer uses a series of belts within individual housings, facilitating high air velocities and significant water evaporation, crucial for efficiently drying products like cornflakes, pet kibble, and biomass pellets.

With its customizable belt lengths and zoned air flow, the BTF-S supports continuous and stage operations, optimizing bulk handling by varying conveyor speeds. This increases both operational efficiency and product quality. The dryer boasts a capacity to handle a wide range of materials from granules to powders, making it suitable for versatile use cases like recycling materials and drying sewage sludge.

Energy efficiency is a key feature, with the option for exhaust air recycling and various heating methods including gas, oil, or biomass boilers. Constructed with maintenance in mind, the machine simplifies cleaning processes and allows significant flexibility in material handling through swing and vibratory conveyors.

STELA supports customization to meet specific process requirements, ensuring the belt dryer seamlessly integrates with existing production lines, particularly beneficial for operations focused on reducing emissions and optimizing resource usage.

Benefits

- Enhances drying efficiency, optimizing air flow for high evaporation rates.

- Cuts energy costs with flexible heat recycling and efficient air zoning.

- Increases product consistency by customizable belt speeds and bulk handling.

- Streamlines operation with seamless integration into diverse production lines.

- Minimizes maintenance downtime with easy access and cleaning design.

- Applications

- Pet food, Pellets, Cement production materials, Recycling materials, Renewable fuels, Agricultural products, Pulp and paper, Herbs, Sewage sludge, Vegetables, Food products, Timber products

- End products

- Muesli base flakes, Biofuels, Cornflakes, Biomass pellets, Vitamin-preserving dried snacks, Dried sewage granules, Granola, Pet kibble, Cement kiln dust, Recycled paper, Dried oregano, Osb boards, Dried onion flakes, Paper pulp

- Steps before

- Harvesting, Washing, Cutting, Sorting, Blanching

- Steps after

- Cooling, Sorting, Packing, Storage, Distribution

- Input ingredients

- leafy crops, herbs, grasses, sea grass, wheat grass, vegetables, onions

- Output ingredients

- dried herbs, dried grasses, dried vegetables, dried onions

- Market info

- Stela Laxhuber is known for their expertise in manufacturing custom-engineered drying systems, particularly belt dryers for biomass, sludge, and food industries, with a reputation for innovation, quality, and energy efficiency in the market.

- Air Velocity

- High, adjustable

- Water Evaporation Rate

- Significant per square meter of belt surface

- Belt Length

- Individually adjustable

- Belt Automation

- Each belt slower than the previous

- Heat Generation Options

- Gas, oil, biomass, electric

- Heat Carrier Options

- Hot water, steam, thermal oil

- Airflow

- Above and below belt, zoned

- System Type

- Exhaust air or recirculation air

- Material Infeed/Discharge

- Swing/vibratory conveyors, slides, discharge conveyors, screws

- Product Compatibility

- High water evaporation, e.g., herbs, grasses, vegetables

- Working mechanism

- Stage dryer with multiple belts

- Integrated steps

- Seamless integration of reversers

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Continuous

- Changeover time

- 0

- CIP/SIP

- Manual cleaning

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleaning method

- Manual

- Airflow control

- From above and below

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat Sensitivity

- Low/Moderate/High

- Water Evaporation Rate

- High/Medium/Low

- Bulk Density

- Low/Medium/High

- Moisture Content

- High/Medium/Low

- Abrasiveness

- Yes/No

- Foaming

- Yes/No

- Container Size and Shape

- Variable

- Particle Size

- Small/Medium/Large

- Viscosity

- Low/Medium/High

- Product Integrity

- Fragile/Durable

- Machine footprint

- Customizable dimensions

- Dryer housing

- Individual per belt

- Installation space

- Generous for high air velocities

- Belt stages

- Multiple, one behind the other

- Belt length

- Individually adjustable

- Airflow configuration

- From above or below

- Bulk height capacity

- Increased for efficiency

- Discharge method

- Vibrating conveyors, slides, or screws

- Belt Length Adjustment

- Individually adjustable

- Heat Generator Options

- Gas, oil, biomass, electric

- Heat Carrier Options

- Hot water, steam, thermal oil

- Airflow System Type

- Exhaust air, recirculation air

- Material Infeed Techniques

- Swing conveyors, vibratory conveyors

- Discharge Techniques

- Vibrating conveyors, discharge slides