Industrial lithium chloride dehumidifier

Efficiently control air moisture and temperature with a solution that ensures precise humidity regulation and energy savings, ideal for facilities that demand optimal environmental conditions for sensitive materials like pharmaceuticals, food, and chemicals.

Controls Humidity and Decontaminates Air

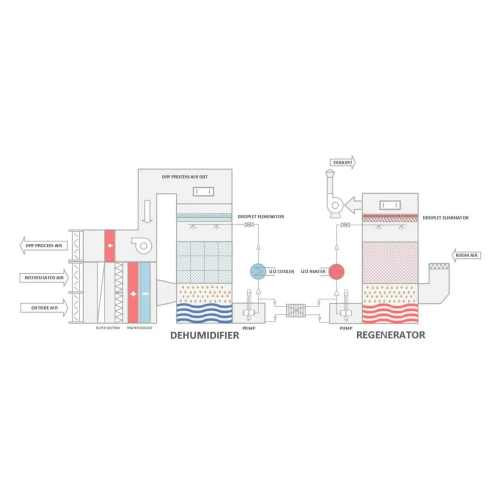

The Lithium Chloride Liquid Desiccant Dehumidifier from TEMA Process utilizes a countercurrent flow system, employing Lithium Chloride to regulate air moisture and temperature. This dehumidifier is vital for applications in the mineral, pharmaceutical, food, and chemical industries, effectively managing moisture in products like gypsum board, pharmaceutical tablets, and animal feed pellets. It operates continuously and facilitates energy-efficient moisture removal by leveraging low-temperature heat sources. Integration into your production line is seamless with automated control systems ensuring 24/7 operation. Constructed for durability, it is suited for environments requiring stringent humidity control and decontamination, featuring reliable performance and minimal maintenance. With customizable options, this dehumidifier supports precise processing needs, maintaining optimal conditions for product quality and compliance with industry standards.

Benefits

- Optimizes production efficiency with continuous 24/7 operation and precise humidity control.

- Lowers operational costs through energy-efficient dehumidification and use of low-temperature heat sources.

- Ensures product integrity and quality by maintaining consistent moisture levels and air purification.

- Enhances environmental sustainability with microbiological decontamination and frost-free cooling.

- Adapts to diverse industrial requirements with customizable system options.

- Applications

- Chemicals, Feed products, Salt products, Plastics, Food products, Minerals, Biomass, Fertilizers, Pharmaceuticals

- End products

- Sodium chloride, Gypsum board, Pharmaceutical tablets, Herbs and spices, Biomass pellets, Pvc granules, Milk powder, Potassium sulfate, Quartz sand, Organic fertilizer, Animal feed pellets, Fish meal, Limestone powder

- Steps before

- Filtering, Heating, Cooling

- Steps after

- Droplet Elimination, Moisture Exhaustion, Humidity Control

- Input ingredients

- outside air, moisture-laden air, room air

- Output ingredients

- dry processed air, exhausted moisture-laden air

- Market info

- TEMA Process is renowned for its expertise in designing and manufacturing industrial drying solutions, specifically fluid bed dryers and coolers, powder processing equipment, and waste material recycling technologies, recognized for efficiency and innovative technologies across various industries.

- Dehumidification Process

- Liquid desiccant using Lithium Chloride

- Control System

- PLC-controlled

- Humidity Control Precision

- ± 1% RH

- Energy Efficiency

- 50-60% more efficient compared to conventional systems

- Regeneration Heat Source

- Low temperature heat sources

- Air Temperature Control

- Adjustable independently

- Moisture Absorption Capacity

- Continuous operation with Lithium Chloride solution

- Cooling Integration

- Frost free cooling

- Droplet Elimination

- Incorporated droplet eliminator in dehumidifier and regenerator

- Working Mechanism

- Countercurrent dehumidification

- Integrated Steps

- Dehumidification and humidification control

- Automation Level

- PLC / SCADA

- Dehumidification and Cooling

- Simultaneous in one system

- Energy Efficiency

- 50-60% more efficient than conventional systems

- Corrosive resistance (e.g. acids)

- Lithium Chloride stability

- Biological compatibility

- Non-toxic, biocide properties

- Cleanability

- Smooth surfaces for easy cleaning

- Density/particle size

- N/A for liquid desiccants

- Control panel type

- PLC/SCADA

- Integration possibilities

- Compatible with existing HVAC systems

- Cooling option

- Cooling tower water / river water

- Flexibility in design

- Dehumidification and humidification possible

- Automation level

- Fully automated with 24/7 operation

- Compact footprint

- Yes

- Customization in humidity control

- Precise ±1% RH control