Continuous twin shaft paddle mixers for dust conditioning

Optimize your mixing process with twin shaft paddle mixers, engineered to handle challenging materials like sludge, powders, and dust, ensuring uniformity and efficiency in conditioning and granulation tasks.

Mixes and Conditions Powders and Sludges

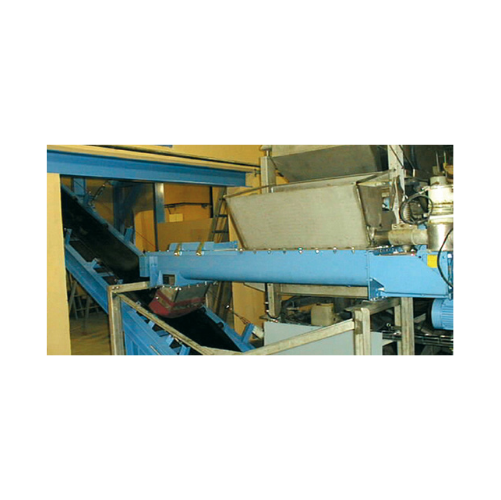

The Continuous Twin Shaft Paddle Mixer MESC-MESC-UM by WAMGROUP is an engineered solution designed to solve complex mixing challenges in various industrial applications. With its dual counter-rotating paddle shafts, the MESC-MESC-UM ensures homogeneous mixing of powders, sludges, and dusts, benefiting operations in sectors from cement and lime processing to biomass and wastewater treatment. Its adaptable paddle angle allows customization for specific material characteristics, enhancing granulation and neutralization efficiency. Supporting capacities from 3 to 70 m³/h, it offers options for integrating up to 20% liquid injection, making it suitable for producing everything from stabilized sewage sludge pellets to gypsum plaster. The mixer is constructed from durable materials, including carbon steel and stainless steel options, to withstand harsh conditions and provide long-lasting performance. Designed with low maintenance costs in mind, it operates continuously, integrating seamlessly into production lines needing reliable, high-capacity mixers. Whether in a construction site or a plastics recycling facility, the MESC-MESC-UM is equipped to handle high-demand mixing tasks efficiently.

Benefits

- Enhances process efficiency with adaptable paddle angles for precise material customization.

- Supports diverse production needs by accommodating up to 20% liquid addition.

- Minimizes maintenance costs with rugged construction from carbon or stainless steel.

- Ensures consistent product quality with reliable continuous operation.

- Reduces labor involvement through its seamless integration into automated production lines.

- Applications

- Lime, Mineral processing, Sludge granulation, Fruit, Dust, Wood biomass, Ash conditioning, Rubber, Gypsum, Plastics recycling, Municipal waste water treatment, Biomass, Biogas digestate, Vegetable processing, Powder mixing, Inerting sludge, Cement

- End products

- Mineral slurry, Dust suppression compounds, Cementitious grout, Wood chips, Stabilized sewage sludge pellets, Wood pellets, Ash treatment additives, Gypsum plaster, Hydrated lime blends, Powdered detergents, Vegetable mash, Recycled plastic pellets, Biogas digestate fertilizer, Treated sewage sludge, Rubber granules, Fruit puree

- Steps before

- Material Preparation, Grinding, Drying, Crushing

- Steps after

- Dust Filtration, Sludge Treatment, Packaging, Discharging

- Input ingredients

- powder, sludge, dust, ash, liquid

- Output ingredients

- homogeneous mixture, granulated sludge, conditioned dust, neutralized sludge

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Capacity

- 3 ~ 70 m³/h

- Liquid Addition

- Up to 20%

- Material of Construction

- Carbon steel or 304L / 316L stainless steel

- Power Rating

- Adapted to application

- Paddle Angle Adjustment

- Available

- Batch vs. continuous operation

- Continuous

- Automation level

- Manual / PLC / SCADA

- Cleaning method

- CIP / Manual

- Corrosive resistance (e.g. acids)

- 304L / 316L stainless steel

- Density/particle size

- Various, depending on type of powder/sludge

- Cleanability

- Yes, suitable for CIP/SIP

- Conditioning Type

- Dust, Sludge

- Tank shape

- Rectangular

- Feed/discharge method

- Continuous

- Mixing paddle angle

- Adjustable

- Material of construction

- Carbon steel / 304L / 316L stainless steel

- Liquid injection

- Available

- Capacity

- 3 ~ 70 m3/h

- Anti-wear coating

- Optional