Tube belt conveyor for long-distance material handling

Ensure seamless and protective transport of bulk materials across challenging terrains and long distances with this advanced tube belt conveyor design, perfect for maintaining material integrity and preventing environmental contamination.

Conveys and Protects Bulk Materials Efficiently

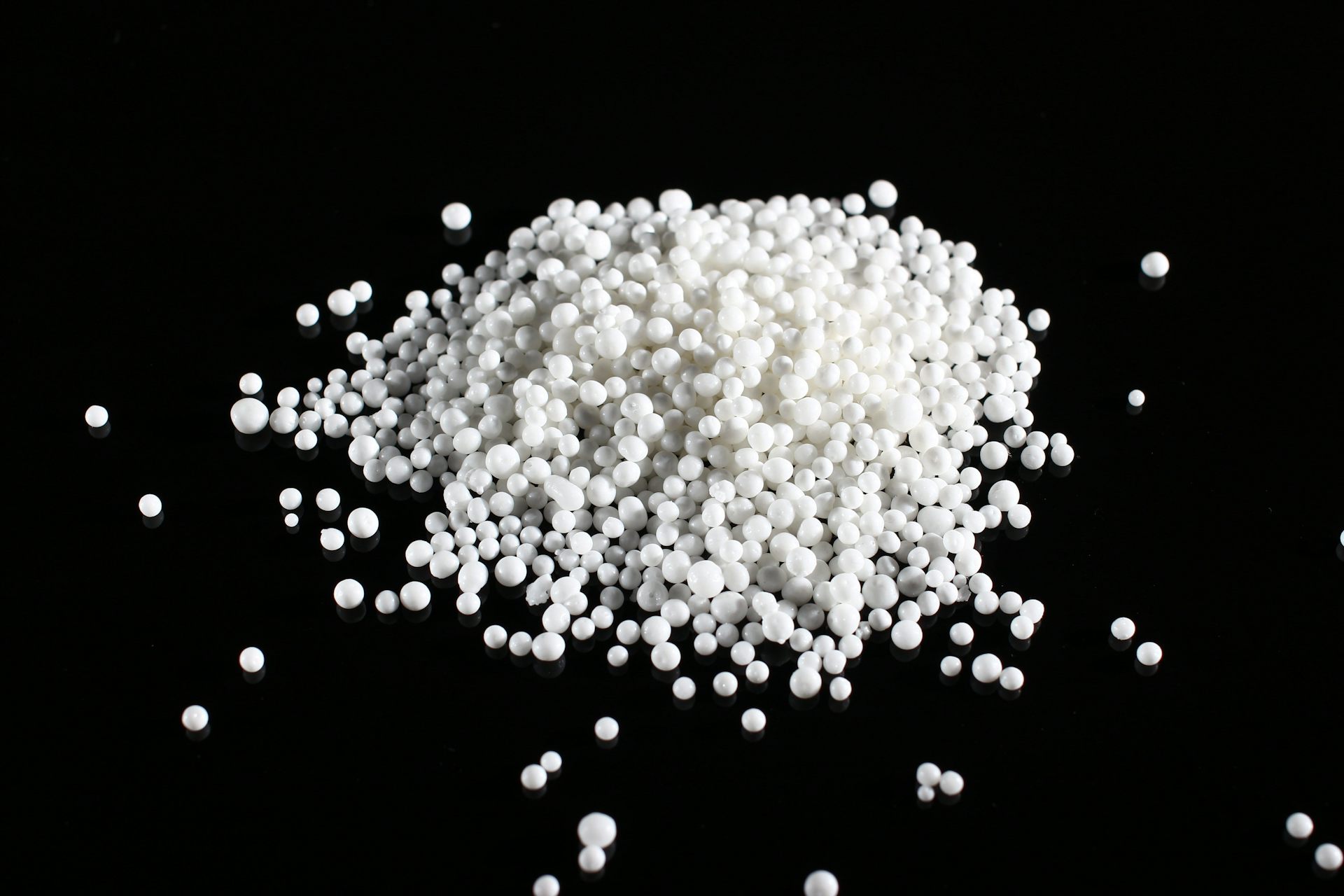

The MoveMaster Tube Belt Conveyor from Schenck Process Group is a versatile solution for transporting bulk materials such as fertilizers, bioplastics, and cement securely over long distances. Specially designed for continuous, automated operations, it features a closed belt system that protects conveyed materials from external elements and prevents material loss. It smoothly integrates into existing plants for applications across chemical, energy, and infrastructure industries. The conveyor can navigate horizontal and vertical curves, making it ideal for rough terrains. With robust mechanical construction, it ensures reliable performance in demanding environments, processing diverse end-products like polyethylene compounds and steel billets. Optional materials like stainless steel are available for added corrosion resistance, supporting compatibility with various industrial materials. Maintenance is streamlined, with easy cleaning access, ensuring minimal downtime and high operational efficiency.

Benefits

- Enhances operational efficiency by seamlessly integrating into existing production lines.

- Minimizes material loss and contamination with a fully enclosed belt design.

- Handles complex terrains, reducing infrastructure costs for long-distance transport.

- Ensures consistent material flow, optimizing productivity in continuous processes.

- Offers material customization options for enhanced durability in challenging environments.

- Applications

- Coke, Bioplastics, Pet food, Compounds, Agrichemicals, Coal, Polyolefins, Steelmaking, Biomass, Batteries, Fertilizers, Recycling, Cement

- End products

- Metallurgical coke, Steel billets, Dry pet food, Polyethylene compounds, Ammonium nitrate, Pulverized coal, Wood pellets, Lithium batteries, Portland cement, Herbicides, Biodegradable bags, Recycled plastics, Polypropylene pellets

- Steps before

- Material Loading, Grinding, Mixing

- Steps after

- Material Discharge, Weighing, Packaging

- Input ingredients

- bulk materials, conveyed material, raw materials

- Output ingredients

- discharged material, processed materials, end product

- Market info

- Schenck Process is known for its expertise in material handling, weighing, feeding, and automation solutions. The company has a strong reputation for delivering high-quality engineered-to-order equipment for diverse industries, backed by innovative technology and customer-centric service.

- Conveying distance

- Long distances

- Terrain adaptability

- Rough terrain, horizontal, vertical curves

- Material protection

- Protected against outside influences

- Environment protection

- Prevent material loss

- Belt closing mechanism

- Special devices for closed pipe

- Automation level

- Automatic belt opening before discharge

- Working mechanism

- Closed belt tube conveyance

- Integration capability

- Easy integration into existing plants

- Material protection

- Material is protected against outside influences

- Environmental protection

- Environment protected against material loss

- Conveying distance

- Long distance capability including horizontal and vertical curves

- Abrasion resistance

- Yes

- Biological compatibility

- No

- Cleanability

- Yes

- Corrosive resistance (e.g. acids)

- No

- Density/particle size

- 0.5–2.5 g/cm³

- Integration

- Easy integration in existing plants

- Integration in existing plants

- Easy

- Terrain suitability

- Long distances, rough terrain

- Curve adaptability

- Horizontal and vertical curves