High capacity cannabis cryo-ethanol extraction system

Accelerate your extraction efficiency with a system that drastically reduces processing time from days to mere hours, ensuring high-purity cannabinoid outputs while seamlessly integrating solvent recovery and decarboxylation into your production line.

Extracts and Reclaims Solvents for Cannabis Processing

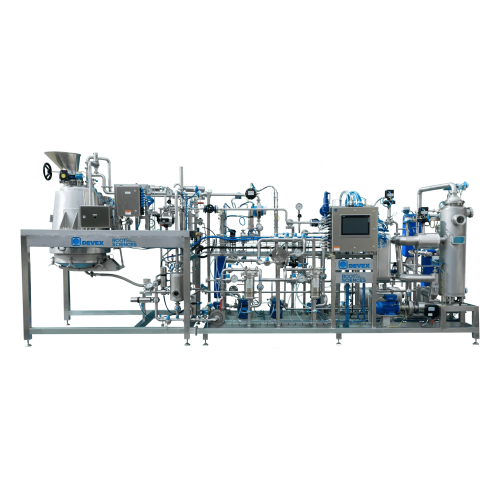

The CryoEXS 400 from Root Sciences is an innovative cryo-ethanol extraction system designed for high-capacity cannabis and hemp processing. This all-in-one solution integrates extraction, solvent recovery, and decarboxylation to streamline operations and reduce processing times. Utilizing a cryogenic approach, it efficiently extracts cannabinoids while leaving lipids behind, eliminating the need for winterization.

With a throughput of up to 400 pounds per 8-hour shift, the CryoEXS 400 caters to large-scale extraction companies and cannabis producers looking to optimize their workflow. The system offers automated, continuous operation through advanced sensors and a touch-screen interface, requiring minimal manpower for monitoring.

State-of-the-art energy efficiency is achieved by recapturing latent heat from cold ethanol post-extraction, resulting in significant utility savings. Constructed for durability, it features stainless steel components that withstand ethanol’s corrosive properties. With compliance to GMP standards, the CryoEXS 400 ensures product quality and safety for biopharmaceutical and nutraceutical applications.

Its modular filtration assembly permits flexible configuration for maintenance ease and element replacement, while a CIP system facilitates thorough cleaning without contamination risks. Tailored engineering support and customizable specifications make this system adaptable to specific processing needs, ensuring seamless integration into any existing production line.

Benefits

- Increases processing efficiency by reducing extraction time from days to hours.

- Cuts labor costs through minimal operator requirements with automated monitoring.

- Ensures cost-effective operation by reclaiming and reusing ethanol.

- Streamlines large-scale output with scalable, high-capacity throughput.

- Enhances product purity by bypassing lipid removal steps.

- Applications

- Nutraceuticals, Hemp, Biopharmaceuticals, Cannabis, Essential oils

- End products

- Cbd oils, Cannabinoid distillates, Nutraceutical supplements, Essential oil concentrates, Hemp extracts, Biopharmaceutical compounds, Full-spectrum hemp oils, Thc extracts, Cannabis isolates

- Steps before

- Biomass Preparation, Grinding, Pre-Extraction Treatment

- Steps after

- Winterization, Distillation, Refinement, Isolation, Product Formulation, Packaging

- Input ingredients

- cannabis biomass, hemp biomass, raw material, ethanol

- Output ingredients

- cannabis crude extract, cannabinoid-rich crude extract, high purity distillates, isolates, concentrate

- Market info

- Root Sciences is known for providing high-quality extraction, distillation, and other processing equipment for the cannabis and hemp industries, offering solutions for creating purified concentrates and extracts, emphasizing efficiency and innovation.

- Throughput Capacity

- 400 lb per 8-hour shift

- Extraction Temperature

- -40°C

- Evaporation Capacity

- 264 kg/h ethanol

- Feed Quantity

- 100 – 800 kg/h

- Evaporation Pressure

- 50-600 mbar (abs)

- Power Consumption

- 67.5 kW

- Machine Dimensions

- 17.62′ x 5.09′ x 7.97′ (L x W x H)

- Automation

- State-of-the-art sensors, controllers, and touch-screen interface

- Integration of Steps

- Solvent cooling, extraction, desolventization, filtration, solvent recovery, decarboxylation

- Automation Level

- State-of-the-art sensors, controllers, touch-screen interface

- Batch vs. Continuous Operation

- Inline Continuous

- Throughput Capacity

- 400 lb per 8-hour shift

- Energy Efficiency

- Recaptures latent heat for lower utility cost

- Cleaning Method

- Manual / CIP options

- Rapid Processing Time

- Reduced from days to hours

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Solvent used

- Ethanol (other solvents on request)

- GMP Compliance

- Yes

- CE marking

- Yes

- FDA materials

- Yes

- Machine Dimensions

- 17.62′ x 5.09′ x 7.97′ (L x W x H)

- Throughput Capability

- 400 lb per 8-hour shift

- Scalable,Skidded System

- 400, 800, and 4, 000 lb throughput options

- Modular Filtration

- Modular and reconfigurable filtration assembly

- Control panel type

- Touch-screen interface

- Integration possibilities

- Automated materials conveyance

- Filtration assembly

- Modular and reconfigurable