Pyrolysis for biomass conversion

Transform diverse waste materials into valuable bio-commodities and energy through advanced thermochemical processes, ensuring efficient resource utilization and environmental sustainability.

Transforms Biomass and Waste into Valuable Outputs

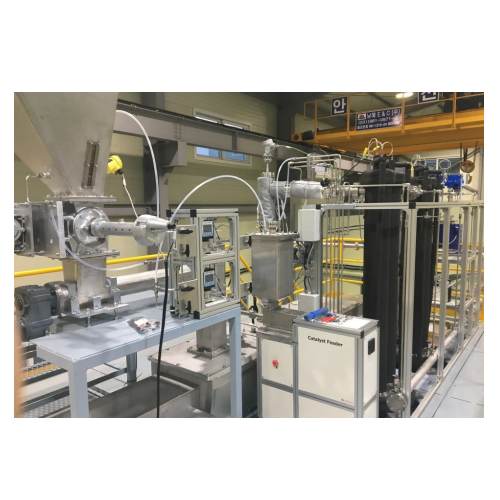

The Spirajoule® from ETIA SAS is a specialized industrial pyrolyzer designed for efficient waste and biomass conversion. Utilizing a robust spiral heating element, it ensures uniform thermal treatment in pyrolysis and torrefaction processes. Ideal for waste management and renewable energy sectors, it converts a wide range of materials, including garden waste, sludge, tires, and plastics, into syngas, biochar, and other valuable by-products. With continuous modular operations, the Spirajoule® system supports integration into existing production lines and allows for flexible processing configurations. Operating between 400°C and 800°C, it offers energy efficiency through optimized motor control, significantly reducing operating costs. The system’s stainless steel construction provides excellent durability and corrosion resistance, accommodating harsh industrial environments. Automated controls and optional remote monitoring enhance operational oversight and facilitate maintenance, ensuring reliable performance and scalability to meet diverse processing needs.

Benefits

- Enhances resource recovery by converting waste into valuable bio-products and energy.

- Lowers operational costs with energy-efficient thermal processing technology.

- Improves processing flexibility with a modular and continuous operation design.

- Minimizes environmental impact through the production of clean syngas for energy use.

- Supports a wide range of materials, catering to diverse industry applications.

- Applications

- Crops, Forest biomass, Srf, Rdf, Sludge, Biochar, Tires, Garden waste, Plastics, Biomass, Rubber

- End products

- Recycled carbon black, Solid fuels, Biocoal, Syngas, Pyrolysis oil, Refining substrate, Liquid for chemical industries

- Steps before

- Drying, Grinding, Shredding

- Steps after

- Packing, Coating, Cooling

- Input ingredients

- garden waste, biomass, sewage sludge, plastics, waste, rubber chips, RDF, SRF

- Output ingredients

- biochar, syngas, pyrolysis oil, biocoal, recycled carbon black, solid fuels

- Market info

- ETIA is known for its expertise in designing and manufacturing advanced thermal processing solutions, including pyrolysis and gasification equipment, for waste management, biomass conversion, and sustainability applications, with a strong reputation for innovation and technology in environmental engineering.

- Operating Temperature

- 400°C to beyond 800°C

- Process Type

- Continuous

- Automation

- PLC-controlled

- Output Products

- Biochar, Syngas, Pyrolysis oil

- Installation Type

- Containerized/Mobile Unit

- Energy Efficiency

- High, due to recovery of syngas as a fuel

- Process Flexibility

- Flexible and modular

- Material Input

- Biomass, waste, rubber, garden waste

- Capacity

- Dependent on plant size and configuration

- Cooling System

- UPK® Cooling System

- Drying System

- Beltomatic® belt dryer

- Operating Temperature Range

- 400°C to 800°C+

- Modularity

- Flexible and modular system

- Continuous Operation

- Continuous treatment available

- Automation level

- Manual / PLC

- Installation Type

- Containerized mobile unit

- Energy Efficiency

- High energy syngas production

- Process Integration

- Integration of drying and pyrolysis

- Output Flexibility

- Biochar, oil, syngas

- Waste Conversion Capability

- Biomass, waste, rubber

- Transportability

- Mobile

- Biological compatibility

- Garden waste, Sludge, Biomass

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- Varies with sensor type used

- Cleanability

- Designed for ease of cleaning with its containerized and modular setup

- Machine Footprint

- Compact, mobile unit

- Operating Temperature Range

- 400°C to 800°C+

- Feed Method

- Continuous

- Discharge Method

- Automatic

- Cooling System

- UPK® Cooling System

- Belt Dryer Type

- Beltomatic®

- Temperature range

- 400°C to 800°C+

- Modularity

- Flexible, containerized unit

- Integration possibilities

- With existing biomass processing systems