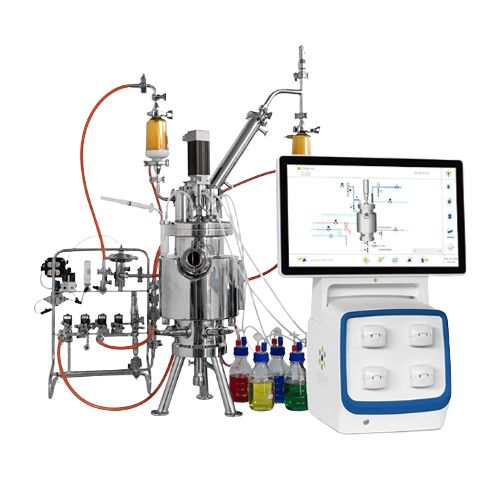

Benchtop Sip fermenter for bioprocessing applications

Optimize your bioprocesses with precise control over fermentation and cultivation, ensuring consistent quality in the production of pharmaceuticals, nutraceuticals, and innovative food technologies.

Facilitates Sterilization, Fermentation, and Cultivation Processes

The GENESIS Benchtop SIP Bioreactor/Fermenter from Solaris Biotech is engineered to advance your R&D and small-scale production with precision and versatility. Designed for biotech companies, pharmaceutical manufacturers, and food producers, it offers multiple configurations for microbial and cell culture processes. This compact unit supports batch, fed-batch, and continuous operations with a working volume range of 7.5 to 20 liters. AISI 316L stainless steel construction ensures durability and corrosion resistance, while the double-jacket system enhances temperature control and heat transfer efficiency.

Equipped with a powerful brushless motor and PLC-based control system, GENESIS allows seamless integration with existing operations. Its flexibility is apparent in the various gas mixing strategies and digital sensor options for accurate monitoring of temperature, pH, dissolved oxygen, and more. Remote access capability, facilitated through user-friendly SCADA software, provides total control and monitoring from any location.

GENESIS is compliant with industry standards and incorporates automatic sterilization systems, including steam and electrical heaters. The equipment’s modular design is further enhanced by the inclusion of Solaris Sterile Liquid Addition System, promoting streamlined operations. Whether you are producing dietary supplements, antitumoral drugs, or fermented foods, GENESIS supports scalability in your production goals while meeting stringent compliance requirements.

Benefits

- Enhances process accuracy with comprehensive digital sensor integration for real-time monitoring.

- Streamlines production scalability with flexible volume configurations and process compatibility.

- Minimizes energy consumption through efficient heat transfer systems and optimized motor control.

- Ensures compliance with industry standards for reliable and safe operations.

- Facilitates remote monitoring and control, reducing the need for onsite management.

- Applications

- Food, Nutraceuticals, Beverage, Biomaterials, Biotech and pharma, Agriculture, Cosmeceutical

- End products

- Plant-based meat substitutes, Coenzyme q10 skincare products, Human vaccines, Wine fermentation starters, Biodegradable polymers, Algae-based fertilizers, Biodegradable plastics, Apis, Antitumoral drugs, Monoclonal antibody formulations, Fermented probiotic drinks, Hyaluronic acid serums, Dietary supplements

- Steps before

- Basic research, Process development, Optimization, Scale-up studies, Scale-down studies

- Steps after

- Analysis, Data extraction, Remote monitoring, Packaging, Quality control

- Input ingredients

- nutraceutical ingredients, dietary supplements, food additives, biotech raw materials, pharmaceutical compounds, cosmeceutical ingredients, bioactive substances, hyaluronic acid precursors, food, beverage raw materials, biomaterial components, agricultural inputs, biofertilizers, biopesticides

- Output ingredients

- antibiotics, antitumorals, human vaccines, APIs, hormones, non-addictive pain killers, monoclonal antibodies, bioactive ingredients, hyaluronic acid, Q10 coenzyme, meat/cheese/wine starters, meat preservatives, cellular agriculture products, flavors, plant-based meat substitutes, low carb drinks, fermented drinks, biopolymers, bioplastics, algae fertilizers

- Market info

- Solaris Biotech is known for manufacturing specialized engineered-to-order bioprocessing equipment, including fermenters and bioreactors, with a strong reputation for innovation, quality, and customization capabilities in the biotechnology and pharmaceutical markets.

- Total volume

- 7.5 L to 20 L

- Vessel material

- AISI 316L

- Sterilization

- Steam, electrical heaters, or both

- H/D ratio

- 2.5

- Impeller type

- Rushton, Marine

- Sparger type

- Toro, Sintered

- Process type

- Batch, fed-batch, continuous

- Control system

- LEM01, PLC-based

- Pumps

- 4 fixed or variable speed peristaltic

- Motor

- Brushless, 1 RPM accuracy

- Gas mixing

- Up to 5 TMFC and/or solenoid valves

- Thermoregulation

- External loops

- Data extraction

- .csv format

- Remote access

- Via PC, tablet, smartphone

- Sterile Liquid Addition System

- SALAS included

- Sight glass

- Illuminated on lid, circular on side

- Batch vs. continuous operation

- Batch / Continuous

- Sterilization Options

- Steam / Electrical Heaters / Combination

- Sterile Liquid Addition System

- Included in Standard Configuration

- Thermoregulation Efficiency

- External, Dedicated Support

- Gas Mixing Strategies

- Up to 5 TMFC / Solenoid Valves

- Control System

- PLC-based with Peristaltic Pumps

- Automation Level

- SCADA / PLC

- Biological compatibility

- AISI 316L stainless steel

- Cleanability

- SIP (Steam-In-Place) capability

- Corrosive resistance (e.g. acids)

- AISI 316L stainless steel

- Research Application

- Basic research

- Process Development

- Process optimization

- Industry Use

- Nutraceutical, Biotech, Pharma, etc.

- Vessel Volume

- 7.5 L, 10 L, 15 L, 20 L

- Vessel Material

- AISI 316L

- H/D Ratio

- 2.5

- Jacket Type

- Double jacket (side-bottom)

- Illuminated Sight Glass

- On vessel lid and side

- Sterilization Method

- Steam, electrical heaters, or combination

- Control panel type

- LEONARDO 3.0 SCADA software

- Integration possibilities

- Up to 24 units managed in parallel

- Motor type

- Brushless motor (1 RPM accuracy)

- Sensors integration

- Modbus digital sensors

- Gas mixing strategies

- Up to 5 TMFC and/or solenoid valves

- Connection options

- Up to 4 analog input/output