Organic rankine cycle for decentralized power generation

Harness waste heat and renewable energy sources to efficiently generate electricity while reducing emissions and energy costs, ensuring a sustainable and profitable power generation process for forward-thinking industrial production facilities.

Generates Electricity from Heat Sources

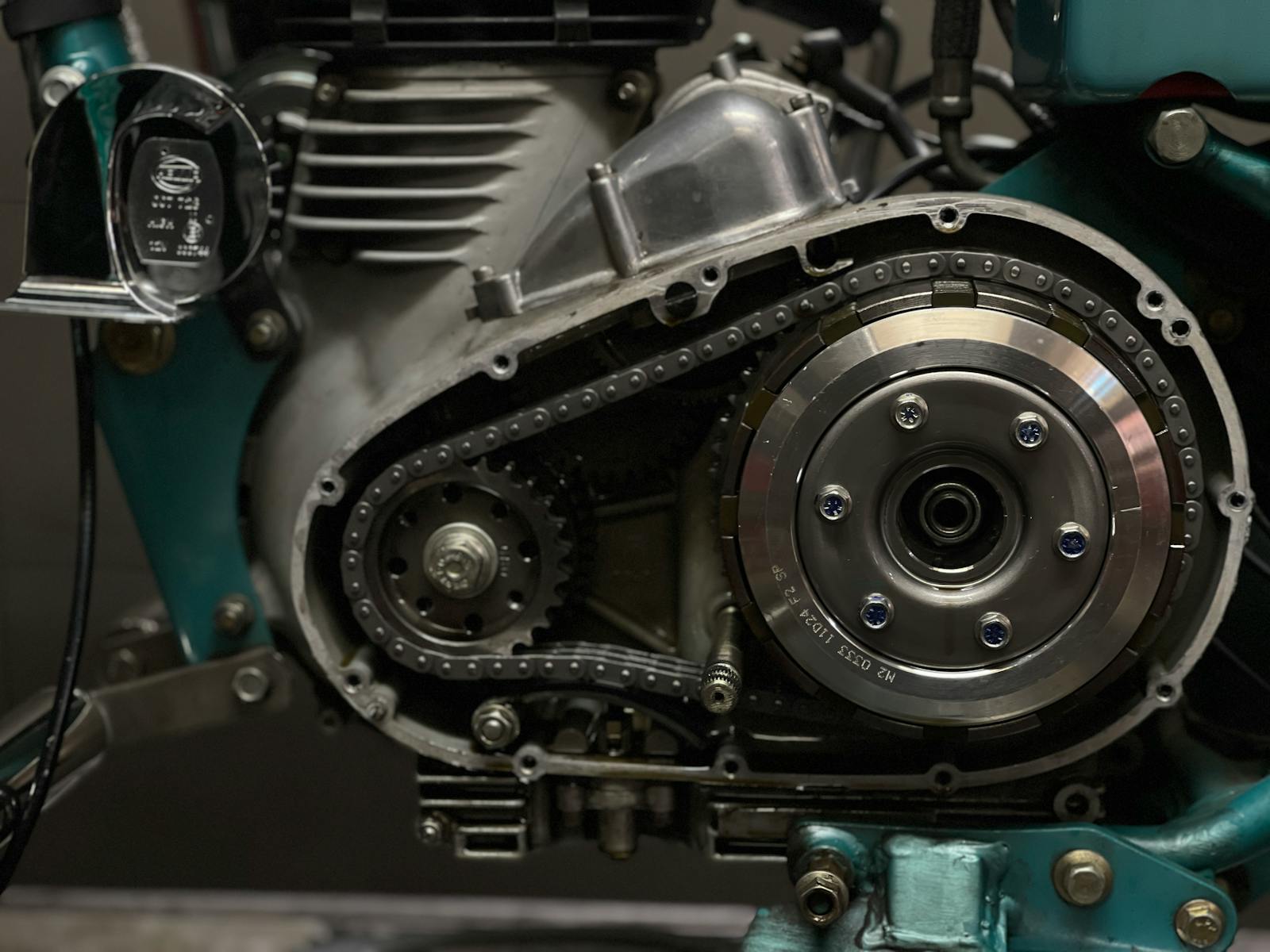

The Cyplan® ORC Power Generation Module from Dürr leverages Organic Rankine Cycle technology to transform heat from various sources into electricity efficiently. The system integrates seamlessly into existing setups, using a compact, skid-mounted design for rapid installation. Its applications range across sectors like biogas, geothermal, and industrial production, producing end-products such as renewable electricity and cogeneration heat. With electrical outputs starting from 50 kW up to 1000 kW, it addresses diverse energy needs while operating with high electrical efficiency. Fully automated operation, remote monitoring, and variable process interfaces ensure optimized performance and easy integration. It also provides useful heat up to 95°C, enhancing its role in combined heat and power applications, and is constructed for minimal maintenance, with hermetically sealed turbines requiring no additional lubricants.

Benefits

- Enhances energy efficiency and reduces costs through combined heat and power generation.

- Minimizes installation time with fully preassembled, skid-mounted modules.

- Optimizes operational performance with remote monitoring and control capabilities.

- Adapts to fluctuating power demands with flexible load management.

- Increases profitability through usage of low- and high-temperature waste heat sources.

- Applications

- Compressor stations, Wellhead generators, Biogas, Geothermal systems, Residual steam, Engines, Modular solar heat power station, Solar heat, Biomass, Thermal exhaust air purification, Hybrid power station, Modular geothermal power stations, Landfill gas, Gas from purification plants, Furnaces, Chp units, Natural gas, Waste, Industrial production processes, Gas turbines, Decentralized electricity

- End products

- Condensed steam, Cogeneration heat, Biogas-derived electricity, Industrial process heating, Residual steam utilization, Modular solar electric power, Wellhead geothermal power, Landfill gas electricity, Renewable energy electricity, Geothermal electricity, Hybrid renewable electricity, Thermal energy, Electricity, Processed waste heat, Combined heat and power, Clean thermal exhaust air

- Steps before

- Heat Transfer, Evaporation, Heating

- Steps after

- Electricity Distribution, Heat Utilization, Condensation

- Input ingredients

- heat source, heat transfer fluid, gas, steam, thermal oil, water, hot water, thermal energy, hot gas

- Output ingredients

- electricity, pressurized vapor, mechanical energy, useful heat, condensation heat

- Market info

- Dürr is known for its expertise in industrial engineering and manufacturing solutions, specializing in automotive painting technology, environmental technology, and production efficiency systems. It has a strong reputation for innovation and quality in engineered-to-order equipment.

- Electrical power output

- 50 – 1, 000 kW

- Heat source temperature level

- >90°C

- Heat source thermal power

- min. 200 kWth

- Internal consumption

- approx. 7% of output

- Heat output for CHP-application

- up to 95°C

- Module dimensions for standard transport

- width < 2, 550 mm, height < 3, 300 mm, length 5, 100 mm up to 12, 500 mm

- Fully automated operation

- Yes

- Remote monitoring and control

- Yes

- Automation level

- Intelligent plant control system

- Automation level

- Fully automated operation

- Energy efficiency

- High efficiency with short payback times

- Batch vs. continuous operation

- Flexible routine operation

- Remote monitoring and control

- Available

- Economical operation

- Reduces energy costs

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- High

- Density/particle size

- Varied

- Abrasion resistance

- Yes

- Machine footprint

- Width < 2, 550 mm, Height < 3, 300 mm, Length 5, 100 mm up to 12, 500 mm

- Control panel type

- Fully automated operation

- Remote monitoring

- Yes

- Modular design

- Skid-mounted, compact module

- Integration possibilities

- Flexible process interfaces

- Installation time

- Short setup time