Continuous twin shaft paddle mixers for sludge conditioning

Optimize your sludge and waste treatment processes with a continuous twin shaft paddle mixer, designed for efficient mixing, granulation, and conditioning to produce dust suppressants, fertilizers, and recycled products, enabling superior resource recovery and environmental compliance.

Mixes and Conditions Industrial Waste Materials

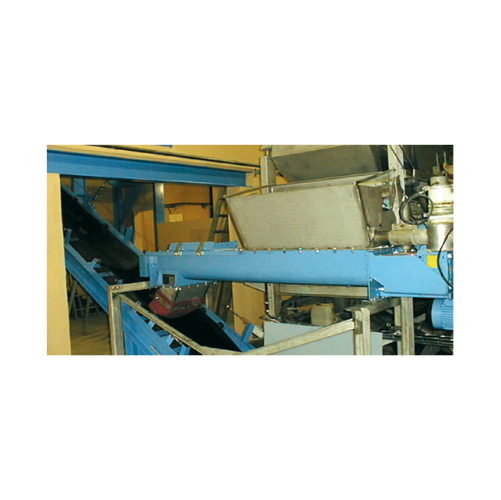

The MESC-MESC-UM Continuous Twin Shaft Paddle Mixer from WAMGROUP is meticulously engineered for industrial and environmental sectors requiring efficient mixing of complex materials. Equipped with dual counter-rotating intermeshing paddle shafts, it offers precise adjustable paddle angles to accommodate various process requirements. This mixer excels in applications spanning from municipal wastewater treatment to biomass conversion, producing consistent outputs like fertilizers and biofuels. With a capacity ranging from 3 to 70 cubic meters per hour, it supports continuous operations effectively. Constructed from carbon steel or stainless steel (304L/316L), it ensures durability and resistance to aggressive materials. Capable of integrating with a plant’s automation system, it reduces energy consumption by utilizing a power rating tailored to specific applications. Maintenance is streamlined through robust design, minimizing downtime in large-scale operations. Customization options, including anti-wear coatings and liquid injection setups, are available to meet specialized processing needs.

Benefits

- Ensures consistent product quality through precise mixing and conditioning.

- Adapts to diverse material characteristics, enhancing process flexibility.

- Handles high capacities efficiently, reducing operational bottlenecks.

- Minimizes maintenance requirements, lowering long-term operational costs.

- Integrates into existing systems, optimizing energy usage and resource allocation.

- Applications

- Organic household waste, Waste water, Dust, Ash, Sludge treatment, Wood biomass in chip form, Sludge, Powders, Biomass, Biogas digestate

- End products

- Fertilizer from treated sludge, Ash-based concrete additives, Compost from organic waste, Powdered chemical mixtures, Dust suppressants, Biofertilizer, Wood pellet fuel, Treated sewage sludge, Recycled wastewater

- Steps before

- Grinding, Drying, Purification

- Steps after

- Conditioning, Sludge Neutralisation, Packaging

- Input ingredients

- powder, sludge, dust, ash

- Output ingredients

- mixed product, neutralized sludge, conditioned dust, granulated sludge

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Capacity

- 3 ~ 70 m3/h (1.8 to 41 cfm)

- Liquid Addition Capability

- Up to 20%

- Material

- Carbon steel or 304L / 316L stainless steel

- Mixing Paddles Angle

- Adjustable

- Counter-rotating Shafts

- 2

- Working mechanism

- Twin shaft paddle mixer

- Integrated steps

- Powder mixing, sludge granulation

- Automation level

- Manual / PLC

- Batch vs. continuous operation

- Continuous

- Mixing process adaptability

- Adjustable angle of inclination

- Maintenance requirement

- Low maintenance costs

- Liquid addition capability

- Up to 20%

- Durability

- Heavy-duty mixing chamber

- Energy efficiency

- Power rating adapted to application

- Abrasion resistance

- Yes

- Corrosive resistance (e.g. acids)

- 304L / 316L stainless steel

- Cleanability

- Designed for easy maintenance

- Density/particle size

- 0.5–2.5 g/cm³ / suitable for powders and sludges

- Material of construction

- Carbon steel, 304L stainless steel, 316L stainless steel

- Paddle angle adjustability

- Allows adaptation to material characteristics

- Angle Adjustment of Mixing Paddles

- Adjustable

- Capacity Range

- 3 ~ 70 m3/h (1.8 to 41 cfm)

- Anti-wear Coating

- Available

- Heavy-duty Mixing Chamber

- Carbon steel / Stainless steel