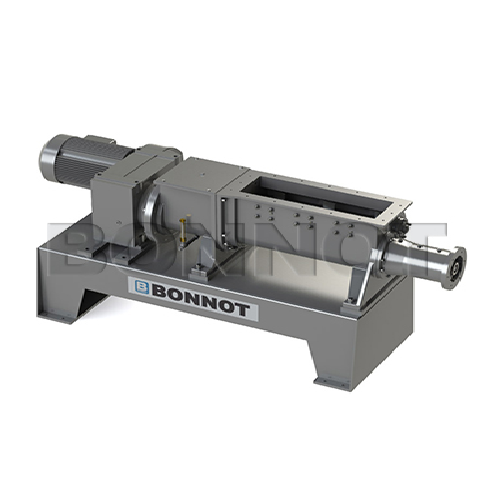

Terrier extruder for high volume material processing

Ideal for continuous high-volume processing, this extruder efficiently handles challenging materials like rubber and sealants, ensuring precise forming and feeding for various applications in your production line.

Processes and Forms Diverse Industrial Materials

The Terrier Extruder from The Bonnot Company is engineered for high-volume material processing, offering robust solutions for industries such as chemical, food, and rubber manufacturing. This extruder employs a high torque drive and a robust gearbox to handle challenging materials with ease. It utilizes a segmented cast screw segment system and heavy-duty thrust bearings, enabling years of cost-effective and low-maintenance operation. Known for its versatility, the Terrier Extruder effectively processes a wide range of applications, from forming silicone sealants and clay bricks to producing activated carbon pellets and cookie dough. Its large hopper design, with optional counter rotating packer, enhances feeding efficiency, especially for difficult materials. With processing capabilities ranging from 5 to over 3500 lbs/hour, and power options up to 75 HP, it integrates seamlessly into continuous production lines, supporting high-volume and automatic operations. Customizable with jacketed components for temperature-sensitive processes, it offers flexible adaptation for specific industry needs.

Benefits

- Enhances production efficiency by handling high volumes with minimal maintenance needs.

- Reduces operational costs using durable components designed for long-term continuous operation.

- Increases material processing flexibility with adaptable configurations for diverse applications.

- Minimizes material handling challenges with advanced feeding mechanisms for difficult materials.

- Supports seamless integration into automated production lines, optimizing overall plant productivity.

- Applications

- Food, Carbon, Sealants, Clay, Ancillary controls, Hydrocolloids, Rodenticides, Firelogs, Catalysts, Rubber, Bulk molding compounds

- End products

- Firelog briquettes, Activated carbon pellets, Catalyst support structures, Silicone sealants, Cookie dough, Phenolic molding compounds, Rubber sheets, Rodenticide bait blocks, Clay bricks, Extruder control systems, Xanthan gum

- Steps before

- Mixing, Material Preparation, Bulk Material Loading

- Steps after

- Cutting, Feasibility Testing, Material Testing

- Input ingredients

- bulk molding compounds, carbon, catalyst, clay, material dewatering, rubber, sealant, firelog materials, food, hydrocolloid, rodenticide

- Output ingredients

- bulk molded compounds, carbon extrusions, catalysts, clay extrusions, dewatered material, rubber extrusions, sealant extrusions, firelogs, formed foods, hydrocolloid extrusions, rodenticides

- Market info

- The Bonnot Company is known for its expertise in manufacturing industrial extruders and cutting equipment, specializing in engineered-to-order solutions for various industries, including food, chemical, and ceramic sectors, with a reputation for quality and innovation.

- Torque

- High Torque Drive

- Gear Box

- Robust Gear Box

- Barrel

- Jacketed, Grooved (optional)

- Counter Rotating Packer

- Available

- Hopper

- Jacketed (optional)

- Output

- 5-15 lbs/hour to 2000 - 3500+ lbs/hour

- Layout

- 21" x 22" x 16" to 78" x 40" x 43"

- Hopper Opening

- 3” x 2.4” to 29" X 9"

- Power

- 0.5 - 3 HP to 75 HP

- Feed system

- Counter Rotating Packer

- Volume capacity

- High volume production

- Durability

- Heavy-duty, robust

- Maintenance

- Easy to Maintain

- Operation history

- Continuous since the 1950's

- Operation environment

- Most severe environments

- Cost of operation

- Low-cost

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- 21" x 22" x 16" / 95" x 30" x 47" / 73" x 30" x 43" / 78" x 40" x 43"

- Hopper Opening

- 3” x 2.4” / 28" x 9" / 29" x 9"

- Model options

- 1 Series / NP4 Series / SP6 Series / SP8 Series

- Customization options

- Jacketed, Grooved Barrel

- Jacketed Hopper

- Control panel type

- Customizable control options

- Hopper configuration

- Jacketed / Counter rotating packer

- Screw segment design

- Segmented cast screw segments

- Gear Box Type

- Robust Gear Box

- Drive

- High Torque Drive

- Barrel Type

- Jacketed / Grooved Barrel

- Power rating

- 0.5 - 75 HP

- Extruder packer

- Optional counter rotating packer