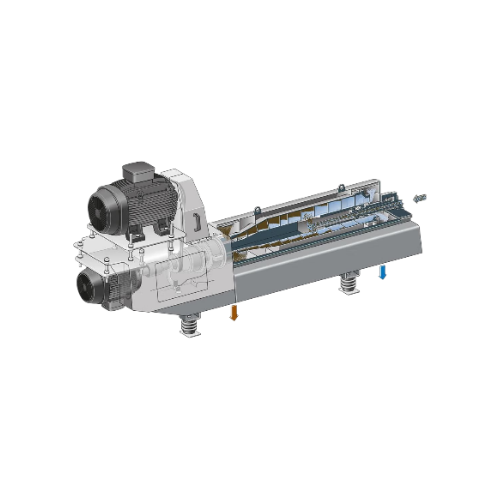

Decanter centrifuge for bioethanol production

Optimize bioethanol production with enhanced separation efficiency, enabling reduced waste and maximized resource recovery, transforming stillage into valuable products like DDGS and corn oil efficiently.

Streamlines Bioethanol Centrifuging and Deoiling

The GEA Decanter Centrifuge is an essential component for bioethanol producers looking to enhance production efficiency. Featuring a deep-pond design and variable frequency drive (VFD), it excels at high-speed separation and deoiling. Capable of processing large volumes continuously, it is integral for transforming slurry into bioethanol, DDGS, and corn oil. With energy efficiency prioritized, this centrifuge reduces consumption by up to 30%, making it cost-effective and environmentally friendly. Its robust construction with wear-resistant tiles and tungsten carbide ensures low maintenance and long service life. Fully automated, it integrates seamlessly into existing systems, offering precision control through advanced PLC interfaces. Available with various material options, it withstands harsh processing conditions, guaranteeing reliable operation in food, beverage, chemical, and agricultural industries.

Benefits

- Enhances production efficiency with continuous high-speed operation.

- Cuts energy costs by up to 30% using optimized discharge design.

- Minimizes maintenance with durable, wear-resistant components.

- Seamlessly integrates into existing systems for improved process control.

- Adapts to variable processing needs with customizable settings.

- Applications

- Animal feed, Ethanol, Bioethanol, Distiller’s grain, Fertilizer, Vinasse, Biofuel, Corn oil

- End products

- Animal feed additive, Fertilizer additive, Dried distiller’s grain with solubles (ddgs), Vinasse concentrate, Corn syrup

- Steps before

- Fermentation, Distillation, Evaporation, Deoiling

- Steps after

- Drying, Animal Feed Production, Fertilizer Production

- Input ingredients

- corn, sugar cane, wheat, molasses, starch-based feedstocks, sugar-based feedstocks, thin stillage

- Output ingredients

- bioethanol, wet cake, thick stillage, syrup, vinasse, DDGS, corn oil, vinasse products

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Separation Efficiency

- Highest

- Drier Cake Achieved

- Yes

- Energy Efficiency

- High

- Discharge Diameter

- Small

- Drive Type

- VFD

- Flexibility

- High

- Bowl Speed Adjustment

- Automatic

- Pond Design

- Deep Pond

- Wear Protection

- Tiles and Tungsten Carbide

- Operation Reliability

- Robust

- Lubrication Type

- Oil + Air

- Energy Savings

- Up to 10%

- Separation efficiency

- High due to deep pond design

- Energy efficiency

- Up to 30% energy saving

- Drier cake production

- Yes

- Automation level

- Automatic differential speed adjustment

- Energy saving features

- Energy Jets

- Robust operation

- External gears and advanced wear protection

- Compact design

- Small footprint, easy access to service parts

- Bowl speed variability

- VFD drive for high flexibility

- Abrasion resistance

- High

- Biological compatibility

- Yes

- Cleanability

- Automated

- Corrosive resistance (e.g. acids)

- High

- Density/particle size

- 0.5–2.5 g/cm³

- Machine Footprint

- Compact Design

- Deep Pond Design

- High g-volume

- Bowl Speed

- Variable Frequency Drive (VFD)

- Small Solids Discharge Diameter

- Energy efficient

- Control Panel Type

- Easy Access for Service

- Energy Jets

- Reduced Energy Consumption

- Discharge Method

- Centrate and Wet Cake Separation

- External Gears

- Robust and Reliable Operation

- Control panel type

- HMI/PLC panel

- Integration Options

- SCADA, DCS compatibility

- Drive System

- VFD (Variable Frequency Drive)

- Material Options

- Stainless Steel, Tungsten Carbide Protection

- Wear Protection

- Tiles and tungsten carbide

- Compact Design

- Small footprint