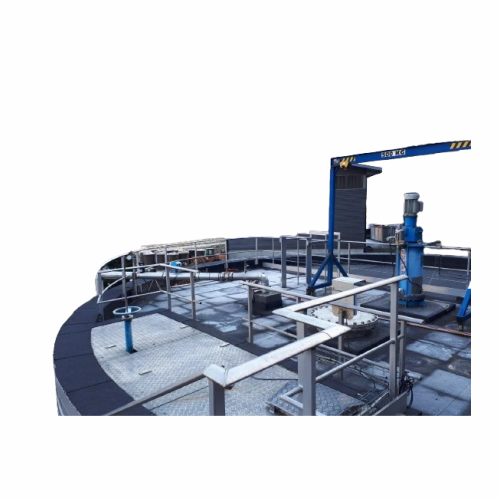

Agitator for biogas digesters in anaerobic digestion

Achieve efficient anaerobic digestion and optimal biogas recovery by maintaining substrate homogeneity and preventing sediment formation, ensuring maximum energy efficiency and continuous operation in your biogas digestion processes.

Ensures Homogeneous Mixing and Temperature Control

The LUMPP Agitator from HASLER Group is designed specifically for biogas digesters and anaerobic digestion processes, providing efficient and continuous mixing to enhance biogas production. This industrial agitator combines large impeller diameters with moderate speeds to ensure high torque without excessive energy consumption. It is equipped with ATEX-certified motors and a robust mechanical seal system to prevent gas leaks, ensuring safe operation in potentially explosive environments. The agitator’s dual-impeller design prevents sedimentation and crust formation, maintaining uniform substrate distribution and consistent temperature throughout the digester. Suitable for wastewater treatment and biomass facilities, it can handle tank volumes from 1,000 to 6,000 m³ and features low-maintenance components for easy servicing. The LUMPP Agitator supports operational efficiency by optimizing digestion time and maximizing biogas recovery, making it an essential component for modern environmental and waste management systems.

Benefits

- Enhances biogas yield by preventing sediment and crust formation.

- Reduces energy consumption with efficient moderate-speed operation.

- Ensures operational safety with ATEX-certified motors and robust sealing.

- Simplifies maintenance through a low-wear hydraulic guard system.

- Accommodates diverse plant sizes, supporting tanks up to 6,000 m³.

- Applications

- Biomass treatment, Waste management, Biogas, Chemical industries, Wastewater treatment, Anaerobic digestion

- End products

- Organic fertilizers, Carbon dioxide, Renewable energy, Methane, Clean water, Treated sewage sludge

- Steps before

- Waste Collection, Substrate Preparation, Pre-Treatment of Organic Waste, Sludge Conditioning

- Steps after

- Biogas Collection, Effluent Treatment, Residual Waste Disposal, Energy Recovery

- Input ingredients

- sewage sludge, food waste, organic industrial waste, manure, post-harvest crop residues

- Output ingredients

- biogas, methane, carbon dioxide

- Market info

- HASLER Group is known for manufacturing and supplying industrial engineered-to-order (ETO) equipment, specializing in mixing, filtration, and sealing solutions for various industries, with a reputation for quality and innovation in handling challenging process applications.

- Motor power

- up to 37 kW

- Hydraulic protection

- 10 to 120 mbar

- Shaft length

- up to 25 metres

- Impeller diameter

- up to 6, 000 mm

- Tank capacity

- from 1, 000 to 6, 000 m³

- Operation

- Continuous (24 hours a day, 7 days a week)

- Automation level

- Continuous PLC

- Energy efficiency

- Up to 37 kW

- Batch vs. continuous operation

- Continuous

- CIP/SIP

- Not specified

- Cleaning method

- Manual/CIP

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tank size

- 1, 000 to 6, 000 m³

- Tank size

- 1, 000 to 6, 000 m³

- Impeller diameter

- up to 6, 000 mm

- Shaft length

- up to 25 metres

- Impeller design

- Streamlined leading edge

- Installation ease

- Simple via special mounting plate

- Maintenance access

- Simplified due to hydraulic guard sealing

- Operation flexibility

- Temporary reverse rotation

- Shaft length

- Up to 25 meters