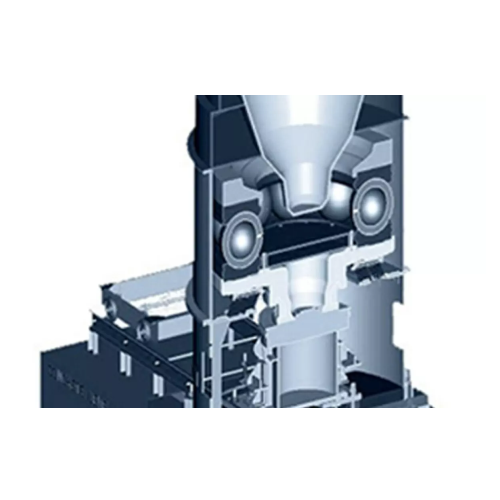

Coal pulverization grinding mill

Maximize efficiency in pulverizing coal with continuous operation and low maintenance, ideal for high-throughput power generation needs.

Pulverizes and Dries Coal and Biomass

The Raymond Ball Race Mill from Schenck Process is designed for efficient grinding and drying of coal, biomass, and various industrial materials. This system features a low-maintenance design, utilizing large diameter hollow balls for consistent pulverization and reduced metal-to-coal contact. Operating within industries such as energy, steelmaking, and chemicals, it ensures optimal size reduction for products like pulverized coal for power generation and granulated fertilizers. Capable of handling up to 40 metric tons per hour, it offers energy efficiency by consuming significantly less power compared to traditional tube mills. The mill is adaptable, functioning at various fineness levels and temperatures to accommodate different material characteristics and moisture contents up to 15%. The system’s integration into existing lines is seamless, providing continuous operation with minimal oversight required, thanks to its robust construction and reliable performance.

Benefits

- Reduces operational costs with low-maintenance design requiring minimal inspections.

- Increases energy efficiency by consuming one-third the power of conventional tube mills.

- Ensures consistent product quality with uniform wear of grinding elements and stable fineness control.

- Enhances flexibility by accommodating various material moisture levels up to 15%.

- Supports continuous operation with high throughput, minimizing production interruptions.

- Applications

- Chemicals, Coal, Polyolefins, Additives, Steelmaking, Biomass, Batteries, Fertilizers, Cement

- End products

- Steel billets, Battery materials, Pulverized coal for power plants, Cement powder, Chemical additives, Granulated fertilizers, Biomass pellets for biomass boilers, Polypropylene pellets

- Steps before

- Coal Handling, Initial Grinding, Moisture Reduction, Size Reduction

- Steps after

- Classification, Fineness Adjustment, Air Separation, Coal Distribution, Ash Handling

- Input ingredients

- coal, high ash abrasive coal, coal particles

- Output ingredients

- pulverized coal, product fineness, dried coal

- Market info

- Schenck Process is known for its expertise in material handling, weighing, feeding, and automation solutions. The company has a strong reputation for delivering high-quality engineered-to-order equipment for diverse industries, backed by innovative technology and customer-centric service.

- Capacity

- 10 to 40 metric tons/hour

- Power Consumption

- 1/3 of same capacity tube mill

- Fineness

- 70% passing 75 microns (200 mesh)

- Moisture Handling

- Up to 15%

- Grinding Elements

- Top and bottom ring with large diameter hollow balls

- Fineness Adjustment

- By changing rotor speed

- Throughput

- Constant

- Reject Rate

- Low

- Ash Handling

- Handles high ash abrasive coal

- Working mechanism

- Ball race mill

- Fineness range

- 70% passing 75 microns (200 mesh)

- Fineness adjustment

- By rotor speed change

- Moisture handling

- Up to 15%

- Power consumption

- 1/3 of same capacity tube mill

- Material drying capability

- Dries out without affecting throughput

- Energy efficiency

- High energy efficiency

- Maintenance frequency

- Low-maintenance design

- Reject rate

- Low reject rate

- Changeover time

- High availability with minimal changeover

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Grinding elements

- Top and bottom ring with large diameter hollow balls

- Ball movements

- Free to rotate about both axes

- Grinding mass arrangement

- Rubbing of coal with coal particles

- Handles moisture content

- Up to 15%

- Fineness adjustment

- Speed of rotor

- Grinding element design

- Top and bottom ring with hollow balls

- Fineness control

- 70% passing 75 microns

- Rotor speed modification

- Yes