Efficient sized biomethane production system

Also referred to as biogas purification, biogas upgrading is an excellent alternative to a CHP (combined heat and power) system that generates heat and electricity. CHP’s are usually expensive and causes air pollution. However, a biogas upgrading system can turn your plant into a sustainable and profitable organization. You thus need a membrane separation technology which is able to upgrade biogas to natural gas quality by filtering out CO2 and other unwanted components.

Separates methane from biogas with more than 99.5% efficiency

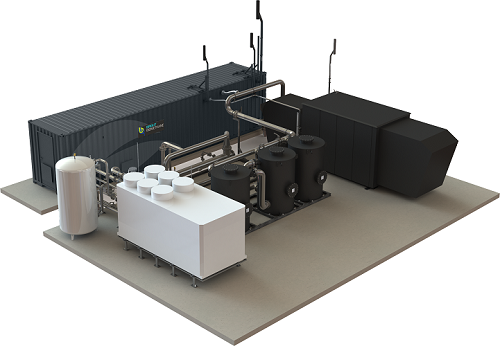

PurePac Grand by Bright Biomethane is a sustainable biogas upgrading solution, ideal for large-scale biomethane production. The membrane separation modules are designed into a 45 ft. container, whereas the pre-treatment and compressor are situated outside the housing. You can also use this model as an indoor unit solution, but the pre-treatment will then have to be placed outside the building.

It is capable of upgrading over 1,000 Nm3/hr of biogas to biomethane, making it ideal for vehicular fuel production and gas grid injection. The unit can also be extended with a carbon dioxide recovery system for food-grade CO2 production, thus creating an additional source of revenue for plant owners.

The patented three-stage membrane separation process ensures that the biomethane is able to meet the requirements of specific applications. Operators can install a special heat recovery system for the production of high-temperature water.

Furthermore, the process does not require water or chemicals, eliminating any disposal problems and unforeseen costs. Lastly, it can produce biomethane from most types of biomass feedstock, including agricultural waste, manure, and municipal wastes and sludges.

Benefits

- Can work with almost all biogas plant types

- Patented control system enables a quick start-up

- Low maintenance and operational costs

- Small carbon footprint with more than 99.5% methane yield