Cubic triaxial tester for biomass flowability

Ensure the smooth flow of chipped and ground biomass with precise material flowability testing, minimizing production downtime and optimizing feedstock management for continuous processing efficiency.

Measures Biomass Material Flow Properties

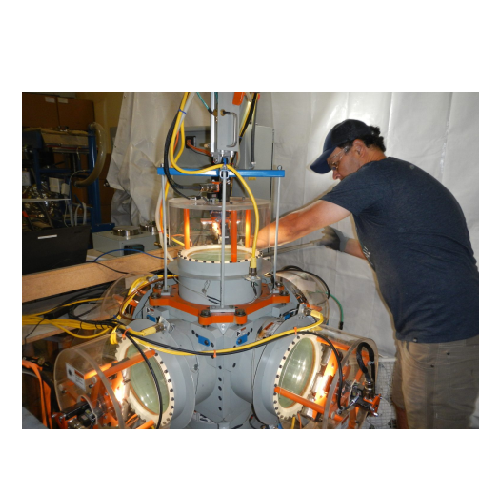

The True Cubical Triaxial Tester from Forest Concepts is engineered to address the critical challenge of biomass material flowability in processing environments. This innovative device simultaneously measures six essential engineering properties to accurately model bulk material flow. Ideal for biomass processors, bioenergy companies, and agricultural research institutions, it helps predict material behavior in hoppers, chutes, and conveyors, mitigating risks of production blockages and reducing downtime.

The testing process is streamlined with a fully automated protocol, managing hydrostatic and conventional tests while requiring manual loading and unloading of samples. The tester offers versatility with 250 mm and 125 mm cubical sample chambers, accommodating a range of formats from millimeter-scale particles to larger structures. An integrated pycnometer with a 1-liter sample volume is also available, enhancing measurement accuracy.

Designed for research and development, laboratory testing, and pre-processing stages, the Cubic Triaxial Tester supports continuous and manual operations, crucial for optimizing material handling strategies. Its robust construction ensures reliability, while Forest Concepts offers customization and engineering support to cater to specific testing needs and operational conditions.

Benefits

- Prevents costly production downtime by identifying potential biomass flow blockages.

- Enables precise modeling of material behavior to optimize system design and performance.

- Reduces operational risks with accurate predictions of flow rates in conveying systems.

- Enhances material evaluation processes with automated data acquisition and analysis.

- Supports diverse testing requirements with adaptable chamber sizes and integrated pycnometer.

- Applications

- Biomass, Wood chips, Ground biomass, Feedstocks

- End products

- Steps before

- Grinding, Chipping, Material Preparation, Sample Loading

- Steps after

- Flowability Analysis, Material Testing, Data Collection and Analysis, Sample Unloading

- Input ingredients

- chipped biomass, ground biomass, wood chips, biomass samples

- Output ingredients

- data sets, engineering properties, flowability data, mass flow rate predictions

- Market info

- Forest Concepts is known for designing and manufacturing innovative biomass processing equipment, specializing in engineered-to-order systems for efficiently handling and converting biomass into valuable products, earning a reputation for quality and innovation in the renewable energy sector.

- Sample Chamber Size

- 250 mm / 125 mm

- Material Size Capability

- Millimeter scale to large formats

- Testing Protocol

- Fully automated

- Pycnometer Sample Volume

- 1 liter

- Data Generation Type

- Hydrostatic and conventional tests

- Working mechanism

- True Cubical Triaxial Testing

- Integrated steps

- Simultaneous measurement of six properties

- Sample chamber size

- 250 mm and 125 mm cubical chambers

- Automation level

- Fully automated testing protocol

- Loading method

- Manual loading and unloading

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Material Flow Prediction

- Bulk Material Flow

- Testing Applications

- Hoppers, Chutes, Auger Conveyors

- Department of Energy Funding Collaboration

- The Pennsylvania State University

- Sample chamber size

- 250 mm / 125 mm

- Pycnometer sample volume

- 1 liter

- Sample chamber size

- 250 mm / 125 mm

- Integrated Pycnometer

- 1 liter sample volume

- Automation Level

- Fully automated protocol