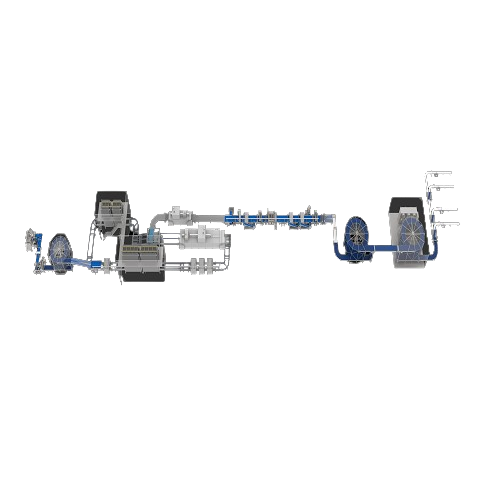

Pressed pan pizza production system

Elevate your pizza production with a system that enhances flexibility and consistency, accommodating a range of crust styles and baking speeds while maintaining sharp focus on operational efficiency and hygiene.

Presses, Moulds, and Bakes Pizza Crusts

The Pressed Pan Pizza Production System from AMF Bakery Systems is engineered to optimize your bakery’s pizza and flatbread production. This system is distinct for its seamless integration of key processes such as mixing, dough distribution, pressing, baking, and cooling, tailored to produce high-volume, quality output. With a capacity to handle up to 30,000 pieces per hour, it caters to commercial and industrial bakeries aiming for a variety of crusts, from thin to thick, including gluten-free and vegan bases.

The system operates continuously to ensure high-speed production while maintaining product consistency. Its PLC-controlled elements facilitate precise automation and integration into existing production lines, while AMFConnect™ offers real-time data access to enhance decision-making and efficiency. The use of advanced materials ensures compliance with food safety standards and ease of cleaning, with components designed for sanitary operation and quick maintenance. Customization is available, supported by AMF’s expert engineering team to tailor the system to specific production needs.

Benefits

- Enhances production efficiency, achieving up to 30,000 pieces per hour.

- Reduces operational costs with real-time data access and monitoring via AMFConnect™.

- Ensures consistent product quality across diverse crust varieties.

- Facilitates easy cleaning and maintenance with sanitary design features.

- Customizable to meet specific versatility in production demands.

- Applications

- Baked goods, Snacks, Flatbreads, Pizza, Pizza crust products, Thin crust pizza, Bakery products, Thick crust pizza

- End products

- Rustic flatbread, Gluten-free pizza shells, Thin crust margherita pizza, Garlic parmesan breadsticks, Stuffed crust pizza, Herb-infused pizza dough, Thick crust pepperoni pizza, Vegan pizza bases, Focaccia bread, Pita bread

- Steps before

- Dough Mixing, Dough Chunking, Dough Feeding, Dough Distribution, Dough Proofing

- Steps after

- Cooling, Freezing, Decorating, Conveying, Packing

- Input ingredients

- dough, toppings, cheese, vegetables, proteins

- Output ingredients

- pressed pan pizza, pizza crust products, thin crust pizza, thick crust pizza

- Market info

- AMF Bakery Systems is known for providing automated bakery equipment solutions, specializing in complete system design and integration for high-speed bread and bun production lines, emphasizing innovation, precision, and reliability in the baking industry.

- Production Speed

- Up to 30, 000 pieces per hour

- Dough Capacity

- Mixing up to 3, 200 lbs

- Transfer Capacity

- Up to 30, 000 lbs/hour

- Automation

- Advanced integrated, real-time system

- Temperature Control

- Independent zone control in tunnel ovens

- Automation level

- PLC / SCADA

- Changeover time

- Minimal due to modular design

- CIP/SIP

- Innovative sanitary design

- Cleaning method

- Easy to clean, toolless removal

- Production capacity

- Up to 30, 000 pieces per hour

- Batch vs. continuous operation

- Continuous

- Energy efficiency

- Integrated energy-efficient systems

- Flexibility

- Designed for high flexibility in production

- Sanitary design

- Open frame, easy access design

- Dough compatibility

- Various pizza dough types

- Food-grade materials

- Stainless steel

- Discharge method

- Belt transfer systems

- Control panel type

- AMFConnect™

- Integration possibilities

- Real-time data access

- Customization for dough handling

- Up to 30, 000 lbs/hour

- Production capacity

- Up to 30, 000 pieces per hour

- Baking system configurability

- Rustic and high-volume output

- Modular design elements

- Available in Vesta Spiral Cooler and Freezer

- Sanitary design

- Open Frame Mixer

- Topping application capabilities

- Targeted decoration