Making Dental Implants

Find innovative production technology for making dental implants and connect directly with world-leading specialists

A missing tooth can wipe a smile off your face. But high-precision engineering is filling the gap with dental implants manufacturing equipment. Advanced technology produces safe implants from biomaterials that fuse with the jawbone.

Select your dental implants process

Tell us about your production challenge

Zirconia can replicate advantages of medical-grade titanium alloys

A lightweight titanium alloy made with 6% aluminum and 4% vanadium, referred to as Ti64, offers high corrosion resistance and biocompatibility. Dental implant therapy rests on the ability of the artificial material to be integrated into the natural bone structure.

But new trends are propelling as an alternative base material for implants. This synthetic mineral favors osseointegration as well, but, unlike titanium, it produces a white color just like natural teeth.

Dental implants manufacturing equipment applied for Metal Injection Molding

Metal Injection Molding (MIM) is one of the main techniques in titanium-based implants. The metal powders are premixed with carbon-free binders to form the mold. The binder is removed before sintering the products and cooling them.

In the case of cast molding, a drilling system threads the interior to accommodate the abutment and crown that orthodontic specialists will fix.

Anodize the outer layer to enhance surface porosity

The particle size distribution of the starting powder is critical to achieving surface roughness in the implant. This allows the product to be anchored in the dental cavity. Implants with smooth finishes need surface texturing to an ideal roughness value between 1 and 10 μm.

Meanwhile, the finished implants are immersed in acid to anodize the metal. The passivation process increases the porosity of the implant, helping the live bone to bind it more easily.

Use conventional heat treatment to sterilize implants

Dental implants are finished to maximum sterility. At the end of the production process, any powder residues or lubricants are cleaned off the implants. Dental implants manufacturing equipment suitable for this process includes vacuum degreasers using solvent vapors. The implants are treated with moist heat or dry heat for sterilization.

Alternative methods include irradiation and chemical processing, but these do not translate into higher effectiveness.

Processing steps involved in dental implants making

Which dental implants technology do you need?

Automatic tube filling and closing solution

Optimize your production line with a high-speed machine for precise tube filli...

Powder flow measurement system

Achieve precise control over powder consistency and prevent process disruptions by assessing ...

Semi-automatic tablet hardness tester

Optimize your tablet production with precise and reliable testing of hardness, dimens...

Tapped density tester for pharmaceutical powders

Ensure precise quality control in pharmaceuticals by accurately measuring...

Dissolution medium preparation system

Streamline your laboratory workflows with a system that prepares and manages dissolut...

Tablet friability tester

Ensure your tablets meet rigorous quality standards by accurately measuring friability and abrasion,...

Real-time Uv-vis analysis for dissolution testing

Efficiently perform dual dissolution tests simultaneously, seamlessly i...

Self-cleaning dissolution tester for automated series testing

Achieve unparalleled precision in dissolution testing with...

High volume 3D shaker mixer for ceramics

Achieving consistent homogeneity and the logistics of handling and introducing lar...

Semi-automatic forming and sealing blister machine

As a manufacturer of medical device, the packaging is a critical facto...

Cold forming aluminum blister machine for capsules

Aluminum blisters are mainly used for packaging products that are sens...

Semiautomatic blister sealing machines for medical devices

Mostly used in the pharmaceutical and medical industries, bli...

Ethylene oxide sterilizer

When medical devices like syringes, catheters, dialysis cartridges, plastic dressings and sutures ...

Entry-level blister packaging machine

Blister packaging is a popular packing method in the pharmaceutical industry thanks t...

Continuous pack cartoner

High volume automatic cartoning is vital for large scale production of cosmetic or pharmaceutical pr...

Automatic blister packaging machine

Automated blister packaging is a popular choice for pharmaceutical production thanks to...

Horizontal cartoner for pharmaceutical applications

Automatic cartoning for cosmetic or pharmaceutical products is a requ...

High-capacity horizontal cartoner for pharma and cosmetics appliances

Cartoners take carton blanks which are formed and...

High capacity cartoner for pharmaceutical applications

Many pharmaceutical products are packed in protective and decorati...

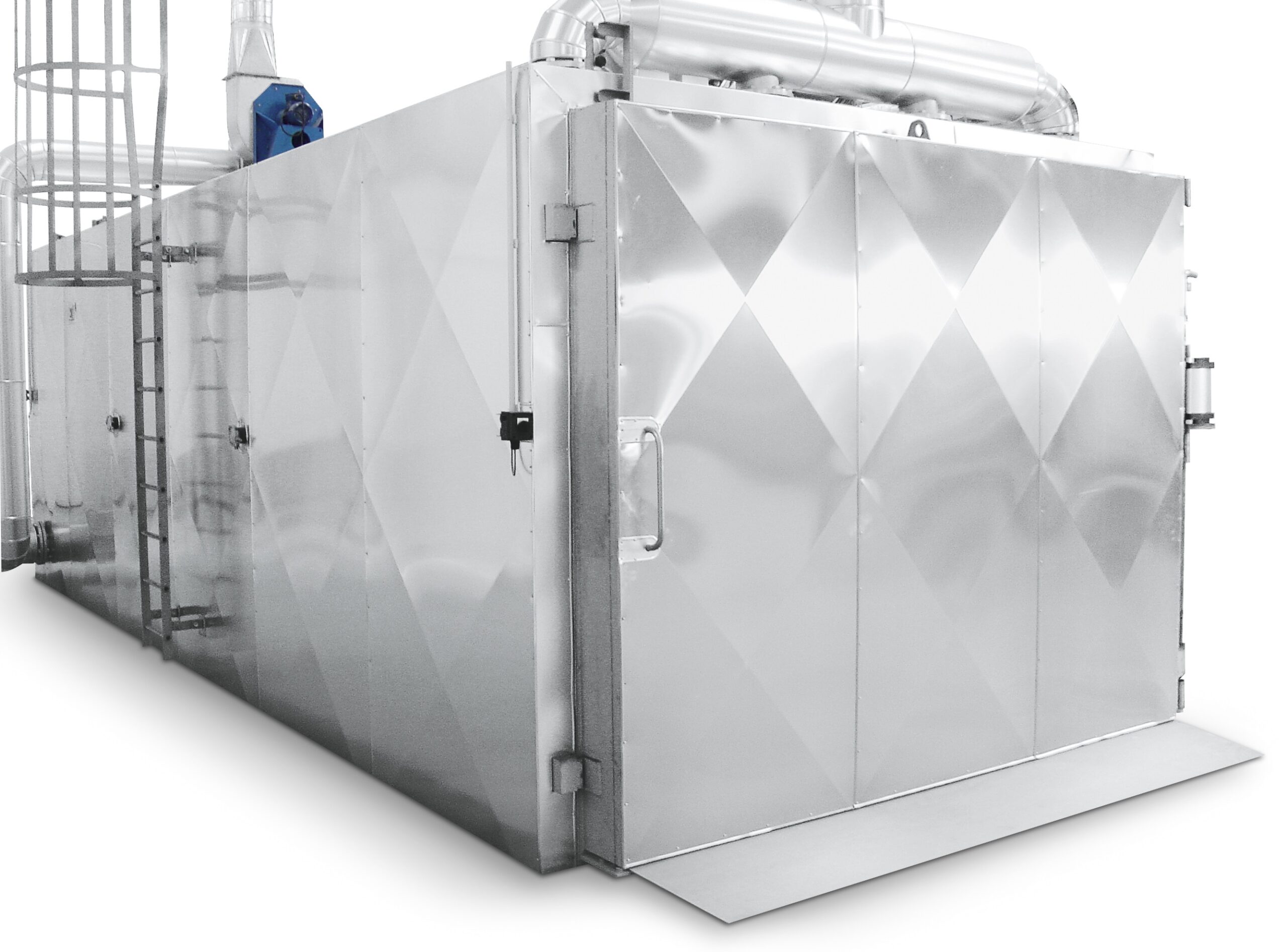

Ethylene oxide sterilization chamber

Designed for the terminal sterilization of temperature sensitive medical-health produc...

Steam and air mixture sterilization autoclave

Specially designed for sterilizing large batches of parenteral solutions.

GMP autoclave

When sterilizing and dealing non-thermolabile products, you will want to get a hold of those resistant to the te...