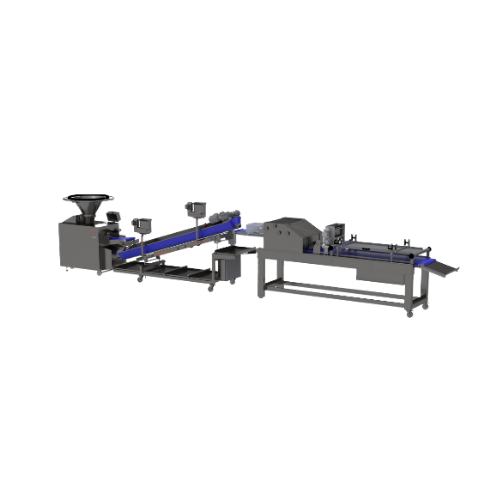

Ryena bread production line for soft dough and ancient grains

Efficiently process soft dough and ancient grains into various artisan breads with precision, ensuring consistent shape and size even without intermediate proofing, thanks to advanced belt rounding technology.

Processes Soft Dough and Ancient Grains Bread

The Ryena Bread Production Line from WP Haton is designed for industrial and artisan bakeries focused on processing delicate dough types. This robust system handles soft wheat, rye, and ancient grains like quinoa and spelt, ensuring that even low-gluten dough maintains its shape and size throughout production.

Using a continuous belt rounding machine, the Ryena Line eliminates the need for intermediate proofing, allowing for seamless transport from dough dividing to moulding. This system is capable of processing up to 3,000 pieces per hour, with a dough weight range between 500 and 2,400 grams, making it ideal for large-scale operations.

Fully PLC-controlled, the Ryena facilitates easy integration into an automated production line, with options for remote monitoring to enhance operational oversight. The user-friendly interface streamlines operations, contributing to significant labor and time savings.

Crafted for efficiency, the equipment’s gentle handling improves dough consistency while its energy-efficient motors help reduce energy consumption. Compliance with industrial automation standards ensures reliable performance, while WP Haton offers engineering support for equipment customization to meet specific production needs.

Benefits

- Ensures consistent dough quality by eliminating intermediate proofing.

- Increases production efficiency, handling up to 3,000 pieces per hour.

- Reduces manual oversight with seamless integration into automated lines.

- Maintains dough integrity and shape, even for low-gluten and delicate doughs.

- Delivers energy savings with optimized motor operation.

- Applications

- Bakery products, Seeded loaves, Ancient grains bread, Soft dough

- End products

- Seeded whole grain bread, Soft rye bread, Quinoa bread, Amaranth bread, Spelt bread, Low-gluten wheat bread, Dinkel bread

- Steps before

- Dividing, Rounding

- Steps after

- Proofing, Moulding, DecoSeeder, Packing

- Input ingredients

- soft wheat dough, rye dough, ancient grains, quinoa, dinkel, amaranth, spelt, low gluten dough, seeded loaves

- Output ingredients

- rounded dough pieces, artisan quality bread, bread without intermediate proofing, dough pieces in constant shape and size

- Market info

- WP Haton is known for producing high-quality, industrial dough processing equipment. They specialize in designing and manufacturing custom engineered-to-order solutions for the baking industry, with a strong reputation for innovation, reliability, and customer service.

- Capacity

- Max. 3, 000 pcs/h

- Dough weight range

- 500 - 2, 400 gr

- Automation

- Highly automated

- Process Type

- Continuous

- Dough compatibility

- Soft wheat/rye, ancient grains

- Proofing time

- Without intermediate proofing

- Dough Handling

- Dough friendly, weight accurate

- Automation level

- Highly Automated

- Batch vs. continuous operation

- Continuous

- Handling of Dough

- Soft wheat/rye, Ancient grains

- Intermediate Proofing Time

- Not required

- Capacity

- Max. 3, 000 pcs/h

- Dough Weight Range

- 500 - 2, 400 gr

- Ancient grains

- Quinoa, dinkel, amaranth, spelt

- Processing method

- Belt rounding machine

- Feed method

- Belt rounding machine

- Discharge method

- From divider to moulder

- Control System

- PLC-controlled

- Integration Possibilities

- Automated Production Units

- Belt Rounding Machine

- Adjustable for Dough Type