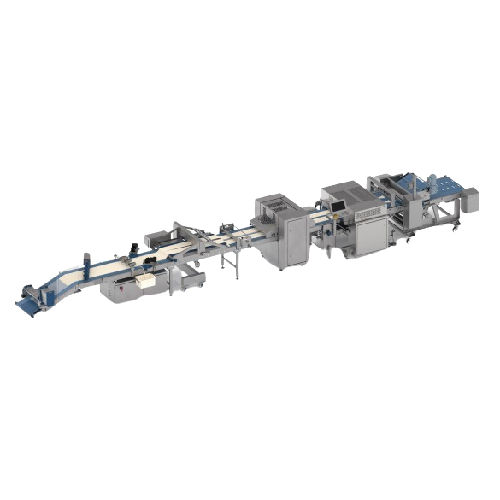

Croissant production module for pastry make-up lines

Enhance your bakery’s product range with a versatile module designed for producing a diverse array of croissants, from mini to filled, ensuring precision and consistency with minimal floorspace requirements.

Expands Croissant Production Capabilities

The Radini Croissant Production Module from Rademaker is a semi-automatic solution designed to integrate seamlessly with your existing pastry make-up line. Specializing in versatility, this module allows you to produce a wide range of croissant styles, from brioche to sourdough, and various shapes, including mini, huge, and filled croissants. It employs a comprehensive process of laminating, sheeting, trimming, cutting, and moulding, ensuring consistent product quality with each batch. Capable of producing up to 9,600 croissants per hour, it offers high throughput for efficient operations. The module features mobile units for easy positioning and cleaning, and is controlled via an intuitive HMI interface, storing recipes for consistent repeatable results. Ideal for bakeries and food processing companies, it supports flexible configurations and delivers robust performance with minimal floor space.

Benefits

- Increases production versatility, allowing a wide range of croissant styles and sizes with minimal reconfiguration.

- Enhances quality consistency with precise control over each stage of the production process.

- Saves space with compact, mobile units that integrate into existing lines with ease.

- Reduces operational downtime through quick assembly and easy cleaning capabilities.

- Supports efficient production with high throughput capacity, optimizing output within a compact footprint.

- Applications

- Pie, Bread, Flatbreads, Pizza, Croissants, Quiche, Pastries, Donuts

- End products

- Pao frances, Brioche croissants, Reihweck, Crescent-shaped croissants, Huge croissants, Pinched croissants, Straight croissants, Reihenweck, Filled croissants, Yeast-leavened croissants, Gipfel, Mini croissants, Bread croissants, Salzstange, Sourdough croissants, Kornspitz

- Steps before

- Dough Laminating, Dough Sheeting

- Steps after

- Croissant Moulding, Croissant Filling, Croissant Baking, Croissant Cooling, Croissant Packaging

- Input ingredients

- Brioche dough, Bread dough, Sourdough, Yeast-leavened dough, Non-laminated dough, Laminated dough, Butter, Margarine, Shortening, Fat, Filling

- Output ingredients

- Mini croissants, Huge croissants, Straight croissants, Crescent-shaped croissants, Pinched croissants, Filled croissants

- Market info

- Rademaker is known for its expertise in manufacturing industrial bakery equipment, offering engineered-to-order solutions. They have a strong reputation for innovative, high-quality machines designed for efficiency and reliability in food production.

- Working width

- 800 mm

- Capacity

- up to 40 rows per minute

- Hourly Output

- Circa 4, 800 croissants on 2 rows per hour

- Hourly Output

- Circa 9, 600 croissants on 4 rows per hour

- Automation

- Controlled by HMI

- Automation level

- Controlled by HMI

- Changeover time

- Minimal due to mobile and interlocked units

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual

- Croissant moulding flexibility

- Various shapes and dough types

- Production capacity

- Up to 9, 600 croissants per hour

- Space efficiency

- Minimal floorspace required

- Product consistency

- Consistent and repeatable products

- Integration with existing lines

- Extension of pastry make-up line

- Mobility

- Units are mobile and easily interlocked

- Cleanability

- Easy to clean, mobile units ensure good accessibility

- Machine footprint

- Comapct

- Control panel type

- HMI-controlled

- Working width

- 800 mm

- Mobile units

- Yes

- Capacity

- up to 9, 600 croissants per hour

- Discharge method

- Manual handling

- Control panel type

- HMI (Human-Machine Interface)

- Integration possibilities

- Interlocked mobile units

- Compact footprint

- Minimal floorspace required

- Mobility

- Mobile frames for easy positioning and removal

- Product versatility

- Various croissant shapes and sizes

- Recipe storage and upload

- Stored in the HMI for consistent and repeatable products

- Moulding options

- Multiple moulder types for various croissant shapes