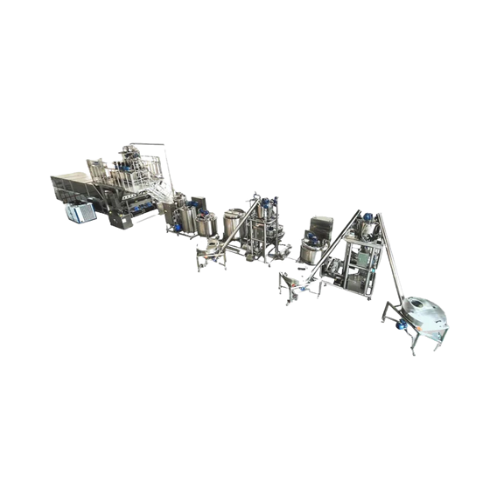

Automatic gummy candy production system

Maximize your confectionery output with a high-speed system capable of producing up to 240,000 gummies per hour, perfect for crafting bi-color and nutrient-enhanced gummy candies efficiently.

Produces High-Speed Gummy Candies

The G-800 Gummy Production System offers an efficient solution for high-speed candy manufacturing, tailored to meet the demands of confectionery, CBD, THC, and vitamin gummy production. With its impressive capacity of up to 240,000 gummies per hour, the system combines a PLC control mechanism with an intuitive LED touch panel for seamless operation. The process integrates molding, mixing, heating, cooling, depositing, and cutting into a continuous flow, enhancing efficiency for diverse gummy formats, including bi-color fruit-flavored, sugar-free, and pectin-based organic gummies. Designed for integration into any production line, the G-800 ensures precision and energy economy with options for electrical or steam heating. Durable construction supports long-term reliability, making it a valuable asset for manufacturers in the food, confectionery, nutraceutical, and cannabis industries. Compliance with industry standards is matched by customizable features and engineering support for tailored solutions.

Benefits

- Achieves high production volumes, reducing overhead by processing up to 800 kg/h.

- Enhances product quality consistency with precise PLC-controlled deposition and molding.

- Lowers operational costs by integrating continuous processing and automated efficiency.

- Decreases energy usage with optimized heating options, tailored to production needs.

- Adapts to diverse product lines, offering versatility for confectionery and nutraceutical products.

- Applications

- Vitamin gummies, Cbd gummies, Thc gummies, Confectionery, Gummy candies

- End products

- Multivitamin gummies, Bi-color fruit-flavored gummies, Thc-infused gummy worms, Sugar-free gummy rings, Pectin-based organic gummy candies, Vitamin c gummies, Cbd-infused gummy bears

- Steps before

- Candy base preparation, Ingredient mixing

- Steps after

- Cooling, Demolding, Quality inspection, Packaging

- Input ingredients

- CBD, THC, Vitamin extracts, Gummy base

- Output ingredients

- Gummies, CBD gummies, THC gummies, Vitamin gummies

- Market info

- Speed

- 240, 000 Gummies/hour

- Production Capacity

- 600-800 kgs/h

- Automation

- PLC-controlled

- Electric Power Needed

- 405KW (Electrically heated) / 174KW (Steam heated)

- Voltage

- 220V/380V/480V

- Compressed Air Consumption

- 1.20 m³/min

- Compressed Air Pressure

- 0.4-0.6 Mpa

- Refrigerator Capacity

- 20HP

- Steam Consumption

- 1T/hr at 0.6MPA

- Vacuum Water Infeed

- 400L/hr

- Dimensions

- 30000x5500x3100 MM

- Gross Weight

- Approximately 12, 000 Kg

- Speed

- 240, 000 Gummies/hour

- Automation level

- PLC-controlled

- Production capacity

- 600-800kgs/h

- Control interface

- LED touch panel

- Heating Type

- Electrically heated / Steam heated

- Cleanability

- Yes

- Density/particle size

- 600-800 kg/h

- Thermal resistance

- 405KW (Electrically heated) / 174KW (Steam heated)

- Machine footprint

- 30000x5500x3100 MM

- Gross Weight

- Approximately 12, 000Kg

- Control panel type

- LED touch panel

- Control panel type

- LED touch panel