Hydraulic curing press for passenger car tires

Optimize tire production with precise molding and curing capabilities designed to enhance tire concentricity, reduce cycle times, and improve energy efficiency.

Cures and Optimizes Tire Concentricity

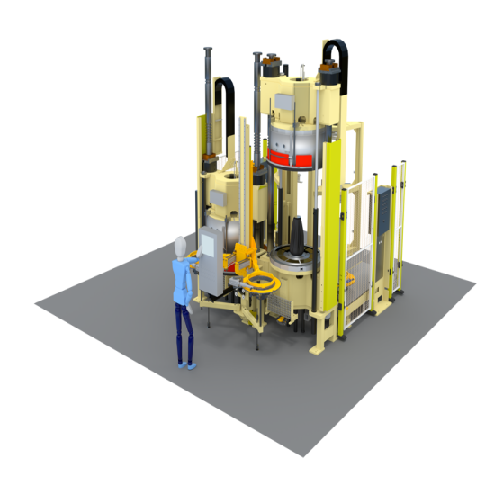

The Hydraulic Curing Press for passenger and industrial tires from HF TireTech Group sets a benchmark in tire manufacturing by integrating modular design with advanced curing technology. This press features a hydraulic column type system developed for versatility and efficiency across a range of tire applications, including passenger car, truck, bus, and light agricultural tires. Its compact structure allows seamless integration into existing production lines, enhancing your infrastructure without extensive modifications.

The press facilitates tire concentricity optimization through precise control mechanisms and a blend of straight and angle type designs, reducing wear and extending the lifecycle of the press components. It operates within industry standards for energy efficiency, employing proven systems that lower energy consumption during the curing process. Configured with main locking and squeeze components outside the heated area, it minimizes thermal wear and ensures uniform tire quality.

With a maximum closing force of up to 2,450 kN, the press accommodates various tire sizes, while its adaptable molding system supports both 2-piece and segmented molds. Automated PLC systems provide integration capabilities for seamless operation and monitoring, and the press adheres to the latest safety and environmental regulations. Available options for heating systems include steam and hot water configurations to suit specific production requirements.

Additionally, HF offers customization options to meet exclusive production needs, supported by comprehensive engineering assistance. This equipment is not only engineered for high-speed, continuous operations but is also designed for easy maintenance, with improved accessibility for routine checks and servicing.

Benefits

- Enhances tire quality and lifespan by optimizing concentricity with precise control mechanisms.

- Minimizes operational costs through energy-efficient systems that reduce power consumption.

- Streamlines integration into existing facilities with a compact, modular design.

- Maintains high production speeds and reduces cycle times, boosting overall throughput.

- Ensures compliance with the latest safety and environmental standards, promoting sustainable operations.

- Applications

- 3-wheeler tires, 2-wheeler tires, Light agricultural tires, Truck tires, Moped tires, Passenger car tires, Scooter tires, Bus tires

- End products

- All-season passenger car tires, Radial tires for light agricultural vehicles, Off-road 2-wheeler tires, Urban scooter tires, City bus tires, Performance passenger car tires, Durable 3-wheeler tires, Heavy-duty truck tires, High-efficiency moped tires

- Steps before

- Mold loading, Green tire placement, Center mechanism setup

- Steps after

- Tire cooling, Post Curing Inflation (PCI), Tire unloading

- Input ingredients

- green tire, mold, hydraulic pressure, heating medium (steam, hot water, N2)

- Output ingredients

- cured tire, energy savings, optimal tire concentricity, reduced wear and longer press life

- Market info

- Schwarte Processing HF FoodTech Group is known for manufacturing engineered-to-order (ETO) industrial equipment, specializing in processing technologies for the food industry, highlighting innovation, high-quality standards, and tailored solutions to meet specific customer needs.

- Cavity control

- Common/Independent

- Max. closing force

- 1.570/1.770/1.960/2.450 kN (160/180/200/250 t-force)

- Min./max. bead diameter

- 12-25 inches

- Max. green tire outer diameter

- 850-1, 000 mm (33.5-39.4 inches)

- Max. cured tire outer diameter

- 850-1, 000 mm (33.5-39.4 inches)

- Max. cured tire height

- 406-450 mm (16-18 inches)

- Type of mold

- 2-piece/segmented

- Max. outer mold diameter

- 1.168-1.321 mm (46-52 inches)

- Min./max. mold height

- 250-610 mm (10-24 inches)

- Heating platen outer diameter

- 1.168-1.321 mm (46-52 inches)

- Center mechanism

- Bag-in-well/standing post (pit or pitless design)

- Green tire stand

- Hanging/shoulder type (single or multiple)

- Pneumatics hydraulic system

- From 1

- Heating system

- Piping and manifold concept (steam/N2, steam/steam, hot water, etc.)

- Safety

- According to local safety standards

- Working Mechanism

- Hydraulic column type

- Integrated Steps

- Loader and unloader chuck

- Modularity

- Customizable with required center mechanism

- Type of Operation

- Straight and angle type press designs

- Energy Efficiency

- Proven energy saving systems

- Maintenance Ease

- Improved access to the important areas

- Design Features

- Compact design, slim solutions

- Availability,Reliability

- Press availability at benchmark level

- Compliance,Safety

- Built to latest safety, environmental, and manufacturing requirements

- Cycle Time

- Improved cycle time

- Customization Level

- Modular build, including PCI options

- Corrosive resistance

- Yes

- Abrasion resistance

- Yes

- Cleanability

- Easy to maintain

- Hydraulic fluid compatibility

- Suitable for various hydraulic fluids

- Compact footprint

- Yes

- Control panel type

- PLC Systems/Automation

- Discharge method

- Loader and unloader chuck

- Modular design

- Available

- Control panel type

- Customized options available

- Integration possibilities

- Modular design for additional components

- Center mechanism

- SMO, loader and unloader chuck

- Green tire stand type

- Hanging or shoulder type

- Cooling conveyors

- With or without PCI

- Center mechanism design

- Bag-in-well/standing post (pit or pitless design)

- Hydraulic system configuration

- From 1