Ai solutions for pizza production in bakeries

Bring unparalleled precision and efficiency to your bakery with intelligent technology, enhancing product consistency and minimizing waste, while seamlessly integrating into your production line for optimized baking operations.

Enhances Pizza and Bakery Production Efficiency

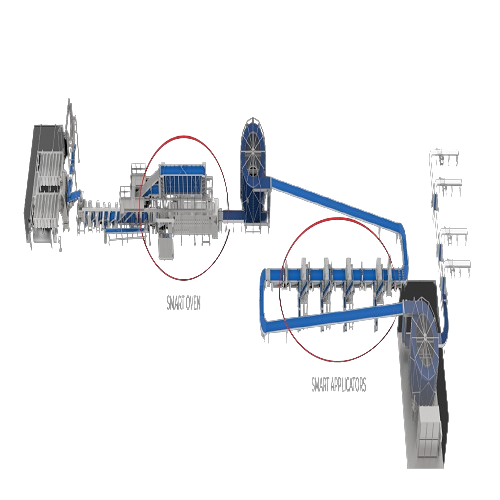

AMF’s Industrial Smart Process Equipment integrates seamlessly into pizza and bakery production lines, offering intelligent automation and data-driven control. This comprehensive system enhances operations from mixing to packaging, ensuring precise ingredient distribution and consistency in high-speed environments. It’s suited for products like Margherita Pizza and Almond Croissants, with capabilities for processes such as dough fermentation, sheeting, and cooling. The equipment boasts smart quality inspection features, automatically compensating for ingredient discrepancies in real-time, and significantly reducing waste. Energy efficiency is achieved through optimized process control, reducing operating costs and environmental impact. Constructed from durable materials, it ensures longevity and easy maintenance, while compliance with industry standards guarantees safe food production. Customizable options are available, supported by engineering expertise for tailored solutions.

Benefits

- Enhances production efficiency by integrating smart automation and quality control.

- Minimizes food waste with precise ingredient application and real-time anomaly detection.

- Reduces energy and CO2 emissions through optimized processing.

- Simplifies maintenance with durable construction and easy-to-clean design.

- Supports scalable production, maintaining consistent product quality.

- Applications

- Buns, Flatbreads, Baguette bread, Handheld snacks, Pizza, English muffins, Pies, Soft bread, Rolls, Cakes, Pastries, Croissants, Artisan bread

- End products

- Sourdough english muffins, Calzones, Red velvet cake, Almond croissants, Chocolate cream pie, Margherita pizza, Potato rolls, Naan, French baguette, Pepperoni pizza, Focaccia bread, Danish pastries, Ciabatta rolls, Brioche buns

- Steps before

- Dough Mixing, Intermediate Proofing, Dough Distribution

- Steps after

- Proofing, Baking, Cooling, Freezing, Conveying, Packaging

- Input ingredients

- un-topped pizza bases, cheeses, proteins, vegetables, dough

- Output ingredients

- topped pizzas, baked pizzas, packed pizzas

- Market info

- AMF Bakery Systems is known for providing automated bakery equipment solutions, specializing in complete system design and integration for high-speed bread and bun production lines, emphasizing innovation, precision, and reliability in the baking industry.

- Automation

- AI-driven

- Accuracy

- ±0.1 g to ±5 g

- Capacity

- High volume production

- Data Connectivity

- Real-time

- Energy Efficiency

- Up to 10% reduction

- Inspection Type

- Vision System

- Quality Control

- Closed-loop

- Environmental Impact

- Reduced CO2 emissions

- Food Waste Reduction

- Significant

- Operator Assistance

- Enhanced AI

- Ingredient Compensation

- Automatic

- Gas Consumption Reduction

- Up to 10%

- Working mechanism

- AI-driven process control

- Integrated steps

- Mixing, proofing, baking, decorating, packaging

- Batch vs. continuous operation

- Inline Continuous

- Automation level

- AI-integrated automation

- Cleaning method

- Remote monitoring

- Energy efficiency

- Data-driven optimization

- Quality inspection

- Real-time anomaly detection

- Sustainability features

- Gas consumption reduction

- Food waste reduction

- Smart solutions for yield increase

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Footprint

- Compact

- Machine configuration

- Inline

- Discharge method

- Automated

- Topping application method

- Pneumatic

- Construction material

- Stainless steel

- Connectivity features

- Integrated digital interface

- Operator interface

- Touchscreen

- Conveyor type

- Multi-belt

- Data monitoring capabilities

- Real-time

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- SCADA / IoT Connectivity

- Automation capabilities

- AI Integration / Self-optimizing