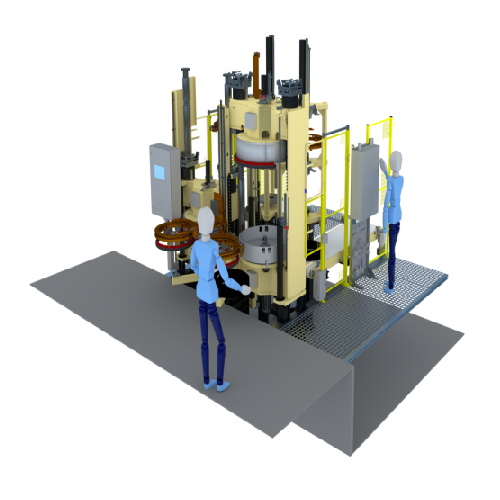

Hydraulic curing press for 2-wheeler and scooter tires

Achieve optimal tire concentricity and extended press life with this hydraulic curing press, designed to meet the growing demand for high-performance two and three-wheeler tires.

Cures and Molds Precision Tires

The Hydraulic Curing Press from HF TireTech Group is engineered to enhance the precision and efficiency of tire manufacturing for 2-wheeler, scooter, moped, and 3-wheeler tires. Leveraging a robust hydraulic system, it molds tires with exact concentricity and consistency. Key features include an optimized heating system for uniform curing and energy efficiency, along with a segmented mold design for flexibility in tire sizes and types. Designed for automated high-speed operations, it integrates seamlessly into existing production lines, minimizing downtime with easy maintenance access. Ideal for tire manufacturers and automotive industry suppliers, it supports multiple media for heating, including steam and hot water, aligning with specific production needs. The press not only improves cycle times but also extends press lifespan due to reduced wear, adhering to the latest safety and environmental standards.

Benefits

- Enhances production efficiency with precise tire concentricity and uniformity.

- Lowers operational costs through energy-efficient heating systems.

- Extends equipment lifespan by reducing wear and maintenance requirements.

- Boosts production versatility with support for various tire sizes and types.

- Ensures compliance with modern safety and environmental regulations.

- Applications

- Scooter tires, 2-wheeler tires, Moped tires, 3-wheeler tires

- End products

- Vespa scooter tires, Tuk-tuk tires, Auto rickshaw tires, Motorcycle tires, Electric scooter tires

- Steps before

- Tire building, Green tire assembly, Mold preparation

- Steps after

- Tire cooling, Post curing inflation, Quality inspection

- Input ingredients

- bias tires, radial tires, green tire, mold, steam, N2, hot water

- Output ingredients

- 2-wheeler tires, scooter tires, mopeds tires, 3-wheeler tires, cured tire

- Market info

- Schwarte Processing HF FoodTech Group is known for manufacturing engineered-to-order (ETO) industrial equipment, specializing in processing technologies for the food industry, highlighting innovation, high-quality standards, and tailored solutions to meet specific customer needs.

- Max. closing force

- 880 kN (90 t-force)

- Tire compatibility

- Bias and radial tires

- Bead diameter

- 10-21 inch

- Green tire outer diameter

- 610 mm (24 inch)

- Cured tire outer diameter

- 720 mm

- Cured tire height

- 250 mm

- Type of mold

- 2-piece/segmented

- Max. mold outer diameter

- 889 mm (35 inch)

- Min./max. mold height

- 100-300 mm (3, 9-11, 8 inch)

- Center mechanism

- standing post (pit or pitless design)

- Green tire stand

- hanging/shoulder type

- Hydraulic system ratio

- from 1

- Heating system arrangement

- piping and manifold concept

- Heating media types

- steam/N2, steam/steam, hot water

- Automation system

- PLC Systems

- Safety standards

- according to local safety standards

- Working Mechanism

- Hydraulic

- Batch vs. Continuous Operation

- Batch

- Energy Efficiency

- Proven energy saving systems

- Automation Level

- PLC

- Maintenance Ease

- Easy access to critical areas

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Control panel type

- PLC

- Mold container type

- 2-piece/segmented

- Center mechanism

- Standing post (pit or pitless design)

- Green tire stand

- Hanging/shoulder type

- Control panel type

- PLC Systems/Automation from main suppliers available