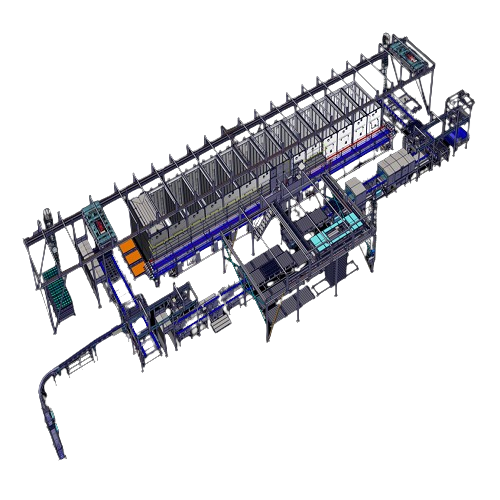

Integrated cooking and chilling system for hams

Streamline your production line with this system that optimizes the shaping, cooking, chilling, and freezing of processed meats, ensuring consistent quality and reduced labor costs while enhancing productivity and energy efficiency.

Shapes, Cooks, Chills, and Freezes Meat Products

The Thermix™ Ham system from Armor Inox offers a fully integrated solution for food processing companies and meat processors, specializing in shaping, cooking, chilling, and freezing hams and other processed meats. Its patented modular cooking and chilling process utilizes immersion with continuous fluid circulation, optimizing process control and product consistency while significantly reducing labor and energy costs. With the ability to handle up to 200 metric tons per day, the Thermix™ is ideal for high-output operations in food and meat processing industries, ensuring complete traceability and food safety. Automation features, including PLC control and the Logi-Flex™ automated handling system, streamline integration into existing production lines. Crafted with durable materials, it provides options for stainless steel construction to combat corrosion. Comprehensive cleaning and maintenance are facilitated by an integrated CIP system, reducing downtime and contamination risks. Customization support is available to tailor the system to specific processing needs.

Benefits

- Enhances product consistency and quality with precise shaping and controlled cooking processes.

- Cuts labor costs by utilizing a fully automated system with minimal personnel requirements.

- Lowers operational expenses with efficient energy use through continuous water circulation.

- Ensures complete traceability from shaping to freezing for improved food safety.

- Increases production capacity, capable of processing up to 200 metric tons daily.

- Applications

- Cooked meats, Ready meals, Sliced meats, Delis, Hams, Hot dogs, Processed meats

- End products

- Packaged sliced meats, Processed cooked meats, Sous vide ready meals, Sliced deli hams, Sliced hot dogs

- Steps before

- Raw Preparation, Molding, Loading

- Steps after

- Slicing, Packaging, Freezing, Unloading

- Input ingredients

- raw meats, uncooked hams, unshaped deli logs

- Output ingredients

- cooked hams, chilled meats, frozen products, shaped slicing logs

- Market info

- Armorinox (Middleby) is known for manufacturing custom-engineered stainless steel solutions for industrial applications, particularly in the food processing and commercial kitchen equipment sectors, focusing on quality, durability, and innovation.

- Capacity

- 20 to 200 metric tons per day

- Labor Requirement

- 2 employees

- Automation

- Fully automated

- Process Method

- Immersion cooking and chilling

- Energy Efficiency

- Large energy savings

- Process Control

- Improved control and consistency

- Product Handling

- Automatic

- Molding Technology

- Multimolds™

- Freezing Capability

- Negative cold solution

- Output Flexibility

- High

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg

- Changeover time

- Quick changeover

- CIP/SIP

- CIP 121°C / SIP 135°C

- Abrasion resistance

- High

- Biological compatibility

- Food-grade

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Stainless Steel

- Density/particle size

- Consistent

- Compact footprint

- Highly compact Multimolds™ technology

- Discharge method

- Automated unloading to slicers, racks, or pallets

- Molding size

- Consistent accurate dimensions

- Modular design

- Patented modular cooking and chilling process

- System integration

- Fully integrated solution for shaping, cooking, chilling, and transferring

- Cooling/Chilling Method

- Continuous circulation of water

- Control panel type

- Touchscreen / PLC

- Integration possibilities

- Seamless integration with existing systems

- Molding options

- Multimolds™ technology

- Automation level

- Fully automated

- Product handling

- Logi-Flex™ automated system

- Output range

- 20 to 200 metric tons per day

- Energy saving options

- Recycling of hot, cold and chilled fluids

- Freezing options

- Negative cold solution

- Food safety features

- Complete traceability

- Process control

- Total control of cook, cool, and chill cycles