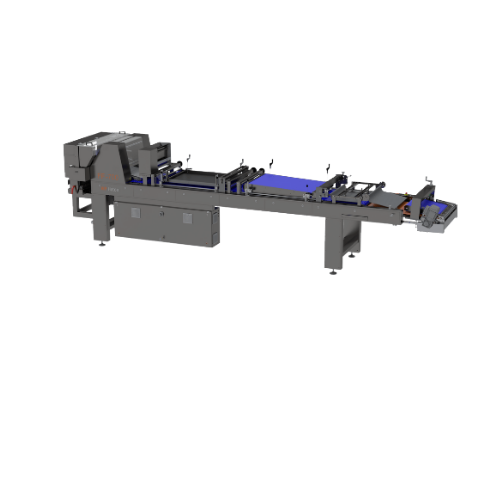

High-speed moulder for baguettes and oblong bread

Streamline your bakery’s production line with a high-speed moulding solution designed for precision shaping of baguettes and oblong loaves, ensuring high throughput while maintaining excellent dough quality.

Moulds and Shapes High-Volume Bread Dough

The FF 700 High-Speed Moulder from WP Haton is engineered for industrial bakeries focused on high-efficiency production of baguettes and oblong bread types. It features a servo-driven centering conveyor that intelligently feeds dough into the system, where a pressure board and adjustable moulding belt shape the dough accurately. This unit excels in high-throughput environments, offering customizable settings to accommodate a range of products from French baguettes to whole wheat oblongs. Designed for seamless integration into existing production lines, it ensures minimal dough stress during shaping and optimal positioning with its centering unit. With an industrial-grade build, the FF 700 integrates modular options for extended functionality and can be tailored to specific bakery needs, ensuring consistent product quality and reduced operational downtime.

Benefits

- Enhances production efficiency with high-speed, continuous operation.

- Minimizes dough stress, ensuring consistent bread quality and texture.

- Reduces labor costs with adjustable, automated moulding settings.

- Offers versatile application for a wide range of bakery products.

- Seamlessly integrates into existing production lines, optimizing workflow.

- Applications

- Bread, Baguettes, Bakery products

- End products

- Whole wheat baguettes, Sandwich sub rolls, French baguettes, Italian ciabatta loaves, Oblong sourdough loaves

- Steps before

- Dough dividing, Dough rounding, Dough proofing

- Steps after

- Panning, Baking

- Input ingredients

- dough pieces

- Output ingredients

- baguettes, oblong types of bread

- Market info

- WP Haton is known for producing high-quality, industrial dough processing equipment. They specialize in designing and manufacturing custom engineered-to-order solutions for the baking industry, with a strong reputation for innovation, reliability, and customer service.

- Speed

- High-speed

- Moulding Quality

- Excellent

- Automation

- Servo driven intelligent centring conveyor

- Adjustments

- Individual adjustments for wide product range

- Pressure Board,Belt

- Adjustable in height

- Moulding speed

- High-speed operation

- Dough centring mechanism

- Servo driven centring conveyor

- Adjustment flexibility

- Individual adjustments available

- Product variety

- Baguettes and oblong bread types

- Height adjustment

- Pressure board and belt adjustable

- Dough handling

- No stress on dough during shaping

- Pressure board options

- Multiple pressure board options

- Belt options

- Multiple belt options

- Dough positioning

- Centring unit for constant positioning

- End processing

- Panning conveyor for further processing

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product types

- Baguettes and oblong bread

- Bread Type Compatibility

- Baguettes/Oblong

- Feed Method

- Servo driven centring conveyor

- Discharge Method

- Panning conveyor

- Pressure Board Option

- Adjustable

- Top Moulding Belt

- Adjustable

- Moulding Quality

- Excellent

- Customization Options

- Multiple pressure board/belt options

- Dough Centring Unit

- Yes

- Dough Stress

- No stress during shaping

- Modular options

- Multiple pressure board and/or belt options

- Centring unit

- Intelligent centring conveyor

- Height adjustability

- Adjustable pressure board and top moulding belt