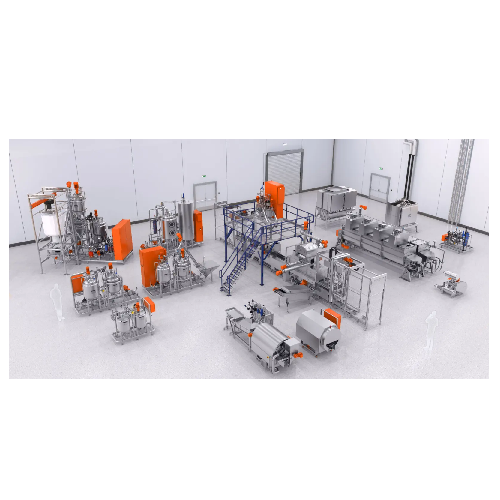

Automatic production line for gummies and nutraceuticals

Maximize the versatility and efficiency of your production space with a compact, fully-integrated line designed for diverse gummy and jelly formulations.

Produces Gummies and Jellies Efficiently

The Tanis 400 Compact is a fully-integrated automatic production line designed to optimize the production of gummies and jellies, including nutraceuticals and cannabis candies. This system stands out for its recipe-driven kitchen and compact footprint, making it ideal for producers with limited space who require high versatility and capacity.

The equipment features a premix preparation system suitable for various gelling agents, utilizing a cone-shaped weighing and mixing vessel to eliminate the need for pre-gelatin dissolving units. Its automatic moulding line, equipped with the T-Gel Depositing Pump, ensures smooth demoulding, starch filling, and printing, effectively replacing traditional machines. High production efficiency is achieved, producing between 400 to 1000 kg per hour.

Incorporating conditioning units ensures the correct starch moisture content, enhancing process safety and achieving optimal printing outcomes. The system is designed for continuous operation with seamless integration into existing production lines. It supports diverse product offerings, including fruit-flavored gummies, vitamin-infused gummies, and vegan options.

Engineered for energy efficiency and customizable configurations, the Tanis 400 Compact includes advanced process control and easy maintenance features. This production line is perfect for confectionery manufacturers, nutraceutical producers, and cannabis candy manufacturers seeking precision and adaptability in competitive markets.

Benefits

- Maximizes production efficiency with a compact footprint, optimizing space utilization.

- Enables versatile product range with fast recipe changeover, expanding market adaptability.

- Reduces operational costs through integrated automatic moulding and conditioning.

- Enhances product quality with precise moisture control for optimal printing results.

- Supports various gelling agents without additional equipment, increasing processing flexibility.

- Applications

- Jellies, Cannabis candy, Nutraceuticals, Confectionery, Gummies

- End products

- Gelatin-free jellies, Herbal gummies, Protein jellies, Vitamin-infused gummies, Cbd gummies, Thc candies, Vegan jellies, Fruit-flavored gummies, Sugar-free gummies

- Steps before

- Recipe Formulation, Ingredient Sourcing, Premix Preparation

- Steps after

- Demoulding, Conditioning, Starch Handling, Packaging

- Input ingredients

- gelling agent, ingredients for gummies, ingredients for jellies, ingredients for nutraceuticals, starch

- Output ingredients

- gummies, jellies, nutraceuticals

- Market info

- Tanis Confectionery is renowned for designing and manufacturing customized equipment for the production of confectionery. They are experts in tailor-made solutions, emphasizing innovative processes and high-quality machinery tailored to meet specific client needs in the confectionery industry.

- Capacity

- 400 - 1000 kg/h

- Automation

- Fully-integrated automatic production line

- Changeover Time

- Fast changeover between recipes

- Footprint

- Compact footprint

- Moulding line type

- Automatic

- Versatility

- Recipe driven and configurable kitchen

- Moisture content control

- Ensures right moisture content

- Automation level

- Fully-integrated automatic

- Batch vs. continuous operation

- Inline Continuous

- Recipe changeover flexibility

- Fast changeover

- Production capacity

- 400 - 1000 kg per hour

- Space efficiency

- Compact footprint

- Biological compatibility

- Suitable for gelling agents

- Cleanability

- Easy-to-clean surfaces

- Corrosive resistance (e.g. acids)

- Industrial-grade materials

- Density/particle size

- Optimized for gelling agent integration

- Footprint

- Compact

- Recipe Configuration

- Various Configurations

- Changeover Time

- Fast

- Control Panel Type

- Automatic