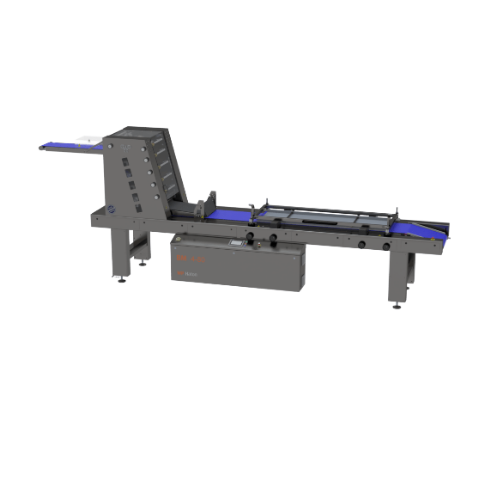

Industrial long moulder for high-capacity dough processing

Optimize your bakery production with a high-speed moulder that ensures consistent sheeting and moulding of dough pieces for perfect long bread products.

Sheets and Moulds High-Capacity Dough Products

The BM 4-80 BT Industrial Long Moulder from WP Haton excels in high-capacity bakery operations, offering precision sheeting and moulding for wheat and wheat/rye doughs. Featuring four independently driven roller pairs, it ensures progressive dough sheeting and minimal handling stress. Capable of processing up to 4,200 dough pieces per hour, this moulder suits industrial bakeries producing baguettes, sandwich loaves, artisan breads, and more. The automated, recipe-driven settings allow seamless integration into existing production lines, improving efficiency with consistent quality control. Ideal for continuous operations, the machine’s air drying feature on the rollers prevents dough sticking, while its modularity supports tailored configurations to specific process requirements.

Benefits

- Enhances productivity by processing up to 4,200 pieces per hour.

- Reduces labor costs through automated, recipe-driven operations.

- Minimizes dough handling stress with independent roller drives.

- Improves product consistency with precise, progressive sheeting.

- Integrates seamlessly into high-capacity bakery production lines.

- Applications

- Dough pieces, Wheat dough products, Long bread, Bakery products, Wheat/rye dough products

- End products

- Baguettes, Rye bread, Sandwich bread loaves, Sub rolls, Hoagie rolls, French bread, Long sandwich rolls, Ciabatta, Artisan bread

- Steps before

- Dividing, Rounding, Proofing

- Steps after

- Packing, Cooling, Final Proofing

- Input ingredients

- wheat dough, wheat/rye dough, round dough pieces, oblong pre-moulded dough pieces

- Output ingredients

- consistent dough products, long moulded dough pieces

- Market info

- WP Haton is known for producing high-quality, industrial dough processing equipment. They specialize in designing and manufacturing custom engineered-to-order solutions for the baking industry, with a strong reputation for innovation, reliability, and customer service.

- Capacity

- Up to 4, 200 pieces per hour

- Automation

- Automated and recipe-driven settings

- Roller Pairs

- Four pairs with individual drives

- Product Handling

- Sheets round and pre-moulded oblong dough pieces

- Dough Type

- Wheat and wheat/rye dough

- Performance

- High performance for industrial lines

- Dough Friendly Handling

- Ensured through automated settings

- Working mechanism

- Four roller pairs with individual drives

- Automation level

- Automated and recipe driven

- Dough handling capability

- Wheat and wheat/rye dough

- Maximum capacity

- Up to 4, 200 pieces per hour

- Product type compatibility

- Round and oblong pre-moulded dough pieces

- Air drying feature

- Air drying device on rollers

- Abrasion resistance

- High

- Biological compatibility

- Suitable for food-grade materials

- Cleanability

- Easy to clean, minimal risk of contamination

- Corrosive resistance (e.g. acids)

- High corrosion resistance

- Density/particle size

- Handles various dough densities

- Control panel type

- Automated and recipe driven

- Compact footprint

- Suitable for high-capacity lines

- Roller pairs

- Four pairs of rollers

- Discharge method

- Progressive sheeting

- Control panel type

- Automated, recipe driven

- Roller drive system

- Individual drive per roller pair

- Integration possibilities

- High-capacity line integration

- Automation level

- Recipe driven for varying dough types

- Drying mechanism

- Air drying on rollers to prevent sticking