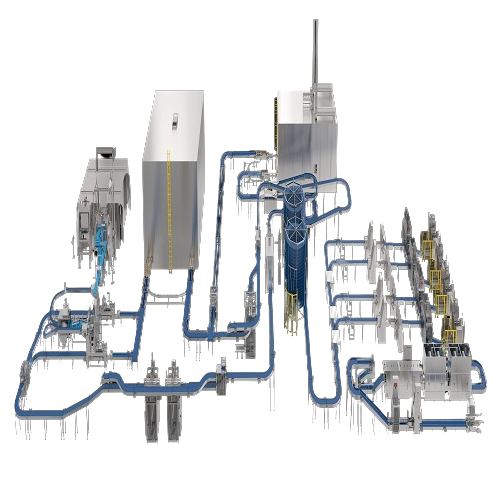

Soft bread production system

Optimize your bakery operations by integrating a high-speed system for producing a wide variety of bread products, ensuring consistent quality, increased throughput, and streamlined processes, all while minimizing operational complexities.

Automates Dough Processing and Bread Production

The High-Speed Bread Production System from AMF Bakery Systems transforms your bakery operations with seamless integration across all production stages. Designed for high-volume demands, it processes up to 13,500 loaves per hour via a comprehensive workflow—mixing, fermenting, dividing, moulding, baking, and packaging. Tailored for diverse applications, it produces everything from sliced whole wheat bread to delicate pastries. Utilizing PLC automation, the system features real-time monitoring, enhancing production through intuitive control and quick adjustments. Constructed from durable, hygienic materials, it supports consistent cleaning and minimal downtime, ensuring reliable performance and product quality. Ideal for commercial and industrial bakeries, it offers bespoke configurations to suit your facility’s needs.

Benefits

- Increases production efficiency by processing up to 13,500 loaves per hour.

- Enhances product consistency and quality through precise control and monitoring.

- Reduces labor costs with automated, integrated operations across all processing stages.

- Minimizes cleaning and maintenance time with hygienic design and easy-access components.

- Offers flexible production capabilities for a wide range of bread and pastry products.

- Applications

- Buns, Muffins, Flatbreads, Sweet pies, Pizza, Danish pastry, Pies, Tin bread, Soft bread, Rolls, Cakes, Pastries, Croissants, Savory pies, Baguette, Swirl bread, Puff pastry, Artisan bread

- End products

- Blueberry muffins, Cheese danish pastries, Pumpkin pie, Chocolate cake, Sourdough artisan loaf, Apple pie, French baguette, Thin crust pizza, Almond croissant, Quiche lorraine, Pullman tin loaves, Cinnamon swirl bread, Sliced whole wheat bread, Flaky puff pastry, Pita bread, Dinner rolls, Brioche buns

- Steps before

- Fermentation, Dough Handling, Mixing, Dough Distribution, Chunking

- Steps after

- Proofing, Baking, Cooling, Slicing, Bagging, Packaging, Product Loading, Stacking, Washing, Drying

- Input ingredients

- flour, water, yeast, salt, sugar, dough

- Output ingredients

- soft bread loaves, buns, pan baked bread

- Market info

- AMF Bakery Systems is known for providing automated bakery equipment solutions, specializing in complete system design and integration for high-speed bread and bun production lines, emphasizing innovation, precision, and reliability in the baking industry.

- Production Speed

- 600 to 13, 500 loaves per hour

- Dough Handling Capacity

- up to 30, 000 lbs./hour

- Mixing Capacity

- up to 3, 200 lbs. dough

- Baking Capacity

- up to 110 loaves per minute

- Stacking Capacity

- up to 40 pans per minute

- Basket Stacking Speed

- up to 28 baskets per minute

- Slicing,Bagging

- automatic dual wicket changer

- Automation

- Advanced Monitoring with AMFConnect™

- Proofing System

- Industry’s leading with most configurations

- Oven Configuration

- Flexible, multi-tier layouts

- Automation Level

- PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover Time

- Short

- CIP/SIP

- CIP Available

- Energy Efficiency

- Optimized for Lower Costs

- Cleaning Method

- CIP / Manual

- Automation Level

- High

- Processing Capacity

- 600 to 13, 500 Loaves per Hour

- Real-time Monitoring

- Available with AMFConnect™

- Cleanability

- Sanitary design

- Corrosion resistance

- Stainless steel components

- Abrasion resistance

- Durable materials

- Biological compatibility

- Food grade materials

- Machine footprint

- Compact design, small footprint

- Basket size

- Standard and cross-nested

- Discharge method

- Automated discharge with conveyors

- Control panel type

- Smart interface with AMFConnect™

- Control panel type

- AMFConnect™ for real-time monitoring

- Integration possibilities

- Modular design for easy integration

- Customization in dough handling

- Custom-designed fermentation room

- Layout flexibility

- Proofer and oven with customizable configurations

- Automation level

- Automated product loading and handling systems

- Product type compatibility

- High-speed system for various bread types

- Space-saving design

- Spiral cooler with compact footprint

- Production capacity

- 600 to 13, 500 loaves per hour