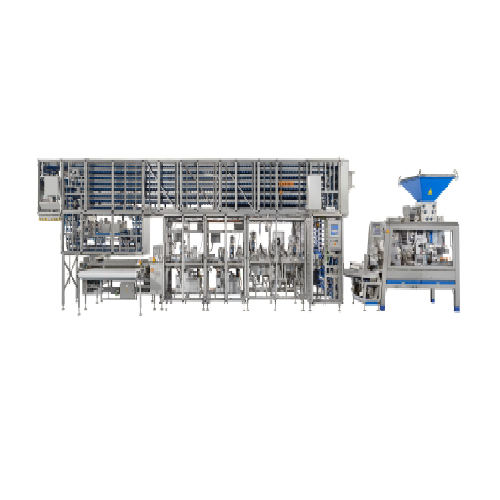

Modular roll line for high-capacity bakery production

Streamline your bakery’s production process with high-speed, flexible roll lines designed to handle everything from classic kaiser rolls to modern flat pressed creations, ensuring consistently high-quality output.

Processes and Moulds Diverse Bakery Rolls and Buns

The Modular Roll Line EVOLUTION by WP Kemper is designed to meet the diverse needs of bakery producers, offering exceptional flexibility and efficiency for producing various rolls and buns. With a modular design that supports automated, high-speed production, this equipment ensures precise molding, proofing, and alignment processes. This roll line is capable of producing up to 43,200 pieces per hour, catering to products like Kaiser rolls, hamburger buns, pain au lait, and more, with a weight range of 25 to 140 grams.

Integration into existing production lines is seamless due to its PLC-controlled system, which also facilitates remote monitoring. The EVOLUTION line is energy-optimized, using direct drives to reduce wear and ensure stable operation. Available with various modules, including cutting and seeding, this system offers customizable configurations for specific product requirements. Hygienic design features, such as washable gauze inserts and transparent doors, simplify maintenance and cleaning. WP Kemper also provides comprehensive engineering support, ensuring the system meets precise production needs and industry standards.

Benefits

- Maximizes production versatility with modular configurations tailored to diverse bakery products.

- Enhances operational efficiency with high-speed throughput up to 43,200 pieces per hour.

- Reduces maintenance costs with a hygienic design featuring washable components.

- Increases product consistency through precise molding and alignment processes.

- Supports seamless integration with existing production lines via PLC-controlled automation.

- Applications

- Kaiser rolls, Hamburger buns, Buns, Stamped rolls, Bread, Sandwiches, Folded rolls, Longmoulded rolls, Rolls, Donuts, Flat pressed rolls, Bakery products, Hot dog buns, Finger rolls, Slit rolls

- End products

- Pain au lait, Sandwich rolls, Roundmoulded rolls, Briochette

- Steps before

- Dough preparation, Dough mixing, Dough dividing

- Steps after

- Proofing, Baking, Cooling, Packaging

- Input ingredients

- dough pieces, raw dough, dough for rolls, dough for buns

- Output ingredients

- high quality rolls, hamburger buns, hot dog buns, kaiser rolls, slit rolls, stamped rolls, longmoulded rolls, folded rolls, sandwiches, finger rolls, roundmoulded rolls

- Market info

- WP Kemper is known for manufacturing high-quality industrial baking equipment, specializing in mixing, dividing, and dough processing solutions, with a strong reputation for innovation, engineering excellence, and reliable service in the bakery industry.

- Rows

- 6-12

- Pieces per hour

- 12, 000 - 43, 200

- Weight range

- 25 - 140 g

- Working width

- 800 mm, 1, 000 mm, 1, 200 mm

- Automation

- PLC-controlled

- Drives

- Direct drives

- Control panel type

- Clear, large touch panel

- Product capacity

- Up to 36, 000 pcs./h

- Modular design

- Customizable and expandable

- Bypass type

- Chain or belt

- Hygienic level maintenance

- Washable, air permeable gauze inserts

- Pre-proofer

- Air conditioned

- Alignment stations

- Equipped in all modules

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Minimal due to modular design

- CIP/SIP

- Washable, air permeable gauze inserts

- Energy efficiency

- Optimized for energy-saving operation

- Cleaning method

- Manual with transparent doors for accessibility

- Hygienic design

- Easy to clean, air-permeable gauze inserts

- Food-grade materials

- Compliance with food safety standards

- Working width

- 800 mm, 1, 000 mm, 1, 200 mm

- Rows

- 6 - 12

- Weight range

- 25 - 140 g

- Pieces/hour

- 12, 000 - 43, 200

- Control panel type

- Large touch panel

- Compact footprint

- Modular and compact design

- Access design

- Transparent hinge-mounted doors

- Tray material

- Plastic trays with removable gauze inserts

- Customization

- Modular and individually adaptable

- Alignment stations

- Included in all modules

- Control panel type

- Touch panel, ergonomic position

- Modular design

- Customizable, expandable

- Tray customization

- Plastic trays with removable gauze inserts

- Machine configuration

- EVOLUTION LINE, EVOLUTION COMPACT

- Connectivity options

- WP CONNECT

- Machine operation mode

- 1-, 2- or 3-shift operation

- Alignment stations

- Included for high processing quality