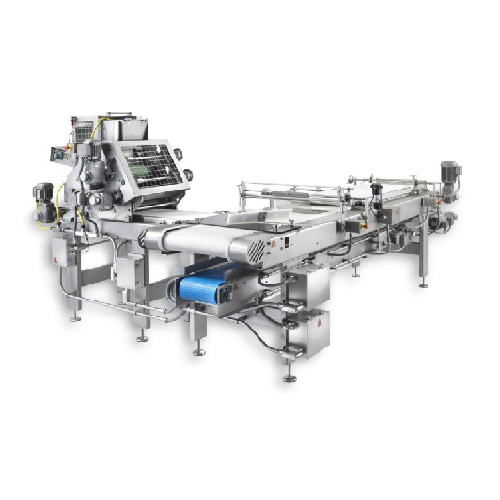

Bread moulders for bakery production

Efficiently shape various bread types like baguettes and ciabatta, ensuring consistent loaf sizes and textures with precise sheeting and moulding processes.

Moulds and Shapes Artisan Bread Loaves

The Shaffer Bread Moulders are designed to meet the demands of industrial baking operations by providing precise moulding for a range of artisan bread products, including French bread, rye, and sourdough loaves. With a capacity range from 6,600 lbs to 32,000 lbs, these moulders offer flexibility for various production scales. The equipment utilizes independent VFD direct drive sheeting rollers, ensuring controlled dough elongation and consistent loaf formation. Integrated with variable speed conveyors and magnetic pan indexing systems, the Shaffer moulders seamlessly fit into automated production lines, enhancing throughput up to 100 pieces per minute. Constructed with stainless steel components for durability, these machines comply with USDA and CE standards and feature easy sanitation access with a conveyor style pressure board. Customization options, including high-speed curling belts and motorized pressure boards, allow for tailored configurations to meet specific production requirements.

Benefits

- Enhances production speed with up to 100 loaves per minute.

- Ensures consistent loaf quality and shape, reducing product wastage.

- Lowers labor costs through automation and minimal manual intervention.

- Facilitates seamless line integration with variable speed conveyors.

- Simplifies maintenance with easy-access, stainless steel construction.

- Applications

- Bread, Loaves, Bakery products

- End products

- Multigrain bread, Rye bread, Sandwich loaves, Baguettes, Brioche loaves, Whole wheat loaves, French bread, Sourdough loaves, Ciabatta, Artisan bread

- Steps before

- Mixing, Dough Chunking, Dough Pumping, Dough Kibbling, Dough Conveying

- Steps after

- Baking, Cooling, Packaging

- Input ingredients

- dough, flour

- Output ingredients

- bread loaves, moulded bread

- Market info

- Shaffer is known for designing and manufacturing industrial mixing equipment, primarily for the baking industry, including dough mixers and processing systems. They are recognized for their expertise in creating customized solutions that enhance efficiency and meet specific customer needs.

- Moulded Bread Length

- 6 to 16 inches (152 to 406 millimeters)

- Loaf Weight

- 8 to 48 ounces (227 to 1361 grams)

- Speed

- Up to 80 or 100 pieces per minute

- Batch Capacity

- 600 to More than 1, 600 lbs

- Material

- Stainless Steel

- Drive Type

- Independent VFD Direct Drive

- Roller Material

- Virgin White Teflon® covered

- Moulding Belt Width

- 22″ Wide

- Compliance

- UL, cUL, BISSC, ANSI, USDA, and CE

- Operating Speed

- 80 to 100 pieces/minute

- Loaf Weight Capacity

- 8 to 48 ounces (227 to 1361 grams)

- Moulded Length

- 6 to 16 inches (152 to 406 millimeters)

- Batch Capacity

- 600 to 1, 600 lbs, More than 1, 600 lbs

- Automation Level

- Operator Interface Controls

- Variable Speed Control

- Flour Dusters and Conveyor Belt

- Pressure Board Adjustment

- Adjustable side guides, height adjustment

- Sanitation

- Hinged Design for Easy Sanitation

- Cleanability

- Easy to clean stainless steel components

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Machine footprint

- Varies by model

- Moulded loaf length

- 6 to 16 inches (152 to 406 mm)

- Moulded loaf weight

- 8 to 48 ounces (227 to 1361 grams)

- Speed

- Up to 80 or 100 pieces per minute

- Material

- Stainless Steel

- Control panel type

- Operator Interface Controls

- Variable Speed Control

- For Flour Dusters and Moulding Belt

- Magnetic Pan Indexing System

- Direct Drive

- Pressure Board

- Motorized, Hinged Design for Sanitation

- Optional Features

- High Speed Curling Belt, Self-Centering Side Guides

- Drive System

- Independent VFD Direct Drive

- Sheeter and Roller Type

- Virgin White Teflon® Covered