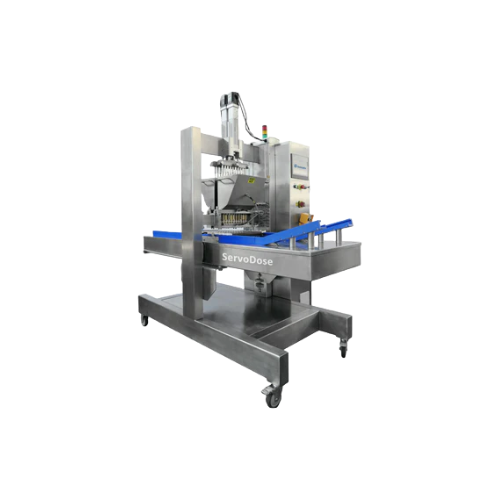

Small-scale gummy candy depositor

Optimize your confectionery production with this manual depositing machine, capable of producing up to 18,000 gummies per hour while ensuring hygienic standards and precise control over gummy weights.

Deposits and Molds Gummies Efficiently

The DM-50 Gummy Depositing Machine from SaintyCo is a vital addition for confectionery manufacturers aiming to streamline their gummy production. This equipment efficiently deposits and molds a spectrum of gummy varieties, from sugar-free to organic options, catering to diverse confectionery needs. With a production rate of 16,000 to 18,000 gummies per hour, it ensures high throughput while maintaining precise weight control, ranging from 2g to 16g per piece. The device features an advanced PLC control system integrated with a user-friendly LED touch panel, allowing seamless operation and monitoring. Its hygienic design upholds the highest standards required for food production, facilitating compliance with stringent health regulations. The DM-50’s manual batch operation suits both small-scale artisanal settings and larger industrial production lines, providing flexibility and efficiency. With a compact footprint and robust construction, this machine promises durability and minimal maintenance, ideal for continuous, demanding confectionery environments.

Benefits

- Ensures high production capacity with up to 18,000 gummies per hour.

- Minimizes labor with user-friendly LED touch controls and intuitive operation.

- Guarantees product consistency across diverse gummy types from 2g to 16g.

- Facilitates compliance with sanitation standards through a hygienic design.

- Offers flexibility for small to large batch processing in manual production lines.

- Applications

- Sweets, Confectionery, Gummies, Candy

- End products

- Gummy worms, Gummy bears, Flavorless, Colorless gummy base, Organic gummies, Pectin-based gummies, Vegan gummies, Sugar-free gummies

- Steps before

- Ingredient Mixing, Gummy Formulation, Heating, Flavor and Color Addition

- Steps after

- Cool Down, Demolding, Packaging, Quality Inspection

- Input ingredients

- gummy base, flavorless, colorless gummy base, melt and pour gummy bases, sugar-free ingredients, vegan pectin, organic materials

- Output ingredients

- gummy candies, gummy bears, gummy worms, simple shapes, rings, delectable treats

- Market info

- Production rate

- 16, 000-18, 000 gummies/hr

- Piece weight range

- 2g to 16g

- Automation

- Advanced PLC control system

- Electric Power Requirement

- 220V 60HZ 3pH 5KWH

- Hopper Size

- 30L

- Dimensions

- 1180 x 786 x 2019 mm

- Weight

- 300kg

- Automation level

- Manual / PLC

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual

- Control system

- Advanced PLC

- Operational ease

- 2 Operators

- Biological compatibility

- Yes

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Yes

- Output Capacity

- 16, 000–18, 000 gummies/hr

- Piece Weight Range

- 2g to 16g

- Healthcare Product Production

- Yes

- Hygienic Design

- Yes

- Machine dimensions

- 1180 x 786 x 2019 mm

- Machine weight

- 300 kg

- Hopper size

- 30 L

- Power requirement

- 220V 60HZ 3pH 5KW

- Control panel type

- LED touch panel