Lipstick production laboratory system

Optimize lipstick production with precise moulding and controlled temperature systems, ensuring consistent quality in every batch, especially for innovative and artisanal cosmetic lines.

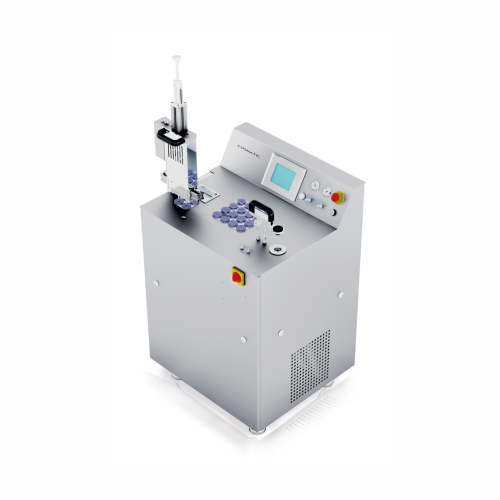

Moulds and Cools Lipstick for Laboratory Production

The SM LABO from Marchesini Group Cosmatic is a versatile lipstick moulding machine designed for laboratory environments. It leverages infrared short-wave technology to precisely heat silicone moulds, maintaining a temperature accuracy of +/-1°C for optimal moulding conditions. This machine is engineered to efficiently produce various lipstick types, including matte, cream, satin, and organic lipsticks. With a production rate of up to 100 pieces per hour, the SM LABO offers capabilities for experimenting with and refining formulations, accommodating up to 16 cooling slots for rapid post-moulding solidification. It features a touch screen interface with PLC for intuitive operation and control, and its energy efficiency is enhanced by eliminating water consumption through an air cooling system capable of reaching -20°C. Ideal for cosmetics manufacturers and research labs focused on quality and innovation, the SM LABO ensures compliance with industry standards while offering customization options for unique production needs.

Benefits

- Ensures precision in lipstick formulation with temperature-controlled infrared heating.

- Enhances production efficiency, cooling up to 16 lipsticks concurrently to -20°C without water consumption.

- Streamlines laboratory operations with a user-friendly touch screen PLC interface.

- Optimizes experimental flexibility by accommodating a wide range of lipstick types.

- Reduces energy consumption with an air-based cooling system, promoting sustainable laboratory practices.

- Applications

- Beauty products, Cosmetics, Lipsticks

- End products

- Cream lipsticks, Hydrating lipsticks, Long-lasting lipsticks, Organic lipsticks, Tinted lip balms, Sheer lipsticks, Liquid lipsticks, Lip crayons, Satin lipsticks, Matte lipsticks

- Steps before

- Material Preparation, Color Mixing, Emulsification

- Steps after

- Cooling, Demoulding, Labelling, Cartoning, Packing

- Input ingredients

- lipstick ingredients, silicone moulds

- Output ingredients

- lipsticks up to 100 pieces/hour

- Market info

- Marchesini (Cosmatic) is known for its expertise in designing and manufacturing customized machinery for the cosmetic industry, including equipment for filling, capping, and cartoning processes, earning a strong reputation for quality and innovation in the market.

- Output Capacity

- Up to 100 pieces/hour

- Temperature Control Accuracy

- ±1°C

- Cooling Temperature

- Up to -20°C

- Heating System

- Infrared short wave (patented)

- Number of Lipsticks in Cooling System

- 16 lipsticks

- Silicone Mould Capacity

- 20 moulds

- Touch Screen Size

- 5" with PLC

- Demoulding Capacity

- 1 lipstick

- Melting Tank Capacity

- 1 liter

- Versions Available

- With or without doser, 2 nozzles

- Operator Requirement

- 1 operator

- Working mechanism

- Soft mould technology

- Cooling method

- Air cooling to -20°C

- Demoulding system

- For 1 lipstick

- Automation level

- Electric panel touch screen with PLC

- Batch vs. continuous operation

- Batch

- Heat control

- Infrared short wave heating

- Temperature control accuracy

- ±1°C

- Capacity

- Up to 100 pieces/hour

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tank size

- 1 liter

- Cooling system

- Air cooled up to -20°C

- Control panel type

- Electric panel touch screen 5” with PLC

- Number of nozzles

- 2 nozzles

- Heating system

- Infrared short wave (patented)

- Silicone moulds

- 20 moulds

- Output capacity

- Up to 100 pieces/hour

- Control panel type

- Electric panel touch screen 5” with PLC

- Cooling system

- Air cooling up to -20°C

- Versions available

- With or without doser, 2 nozzles and melting tank

- Heating system

- Infrared short wave (patented)

- Demoulding system

- For 1 lipstick