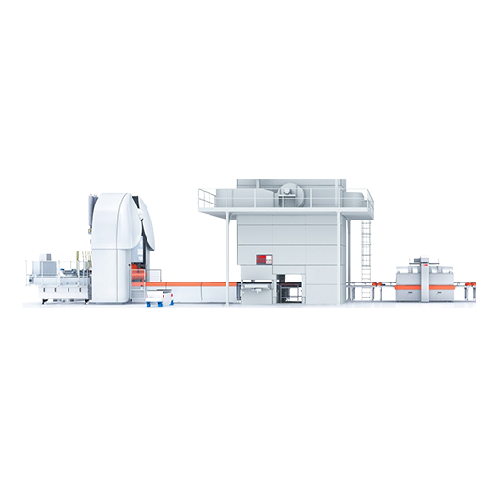

Advanced ceramic tile production line

Elevate your ceramic tile production with an all-encompassing solution that seamlessly streamlines moulding to packaging while ensuring energy efficiency and reduced environmental impact, optimizing every step to deliver high-quality results from standard tiles to large decorative panels.

Integrates and Optimizes Ceramic Tile Production

The SACMI SMART CORE LINE is an advanced ceramic tile production system designed to seamlessly integrate and enhance the efficiency of your manufacturing process. This system offers comprehensive solutions from initial moulding to final packaging, addressing the intricacies of producing high-quality porcelain, glazed, and stoneware tiles, as well as large format slabs and decorative panels. Utilizing an array of precise machines such as ceramic hydraulic presses, digital decorating machines, and energy-saving roller kilns, the SACMI SMART CORE LINE ensures optimum workflow and product consistency.

The system supports continuous, automated, high-speed operations, with modular design options for tailored deployment in diverse ceramics and advanced materials industries. Intelligent integration enables effective material mixing, conveying, and pressing, with digital monitoring for real-time process adjustments, ensuring consistent throughput and quality. The equipment’s energy and environmental efficiencies are enhanced by energy recovery systems and comprehensive dust removal technologies.

Moreover, the SACMI Continua+ technology facilitates large tile production with varying dimensions and thicknesses, while the innovative Deep Digital system offers cutting-edge decoration capabilities. By incorporating these advanced technologies into the production line, manufacturers benefit from reduced energy consumption and improved environmental impact. With built-in automation and comprehensive sorting, packaging, and handling systems, the SACMI SMART CORE LINE represents a streamlined, efficient, and scalable solution for modern ceramic tile production.

Benefits

- Enhances production efficiency by integrating moulding, drying, and firing processes.

- Reduces energy consumption with advanced roller kiln technology.

- Improves product quality and consistency with real-time digital monitoring.

- Reduces environmental impact through energy recovery and dust removal systems.

- Increases operational flexibility with modular design for scalable production.

- Applications

- Ceramic slabs, Ceramic tiles

- End products

- Porcelain tiles, Stoneware tiles, Digital printed ceramic tiles, Large format ceramic slabs, Decorative ceramic panels, Glazed ceramic tiles

- Steps before

- Raw material batching, Raw material loading, Recipe dosage, Powder atomization

- Steps after

- Glazing, Surface finishing, Format cutting, Sorting, Packaging

- Input ingredients

- raw materials, ceramic mixtures, glaze, powders, tiles, ceramic slabs

- Output ingredients

- ceramic tiles, ceramic slabs, finished products, packaged tiles, packaged slabs

- Market info

- Sacmi is renowned for manufacturing advanced industrial equipment, primarily focusing on ceramics, packaging, and food processing. With a commitment to innovation and quality, Sacmi is a market leader in providing engineered-to-order solutions across various sectors.

- Automation

- Automated management from batching to ensiling

- Energy Efficiency

- Energy savings and reduced consumption

- Production Quality

- High quality and consistency

- Firing System

- Roller kilns for uniform firing

- Moulding System

- Hydraulic presses

- Decoration System

- Deep Digital technology

- Pneumatic Conveying

- Dense and semi-dense phase

- Drying System

- Horizontal and vertical thermal machines

- Filtration

- Dry and wet filtration systems

- Cooling System

- Energy recovery systems

- Powder Production

- Atomisation

- Batch Management

- Complete range of batch mills

- Storage System

- Automated vehicles for handling

- Packaging System

- Automatic sorting and packaging lines

- Digital Manufacturing Platform

- Smart Factory control

- Capacity

- Production of large slabs and various tile sizes

- Process Repeatability

- Ensures process control and repeatability

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact design

- Discharge method

- Automated unloading

- Pneumatic conveying system

- Dense and semi-dense phase

- Control panel type

- Digital interface

- Glazing lines and accessories

- Suitable for regular sizes and large slabs

- Control panel type

- Digital/Touchscreen

- Integration possibilities

- ERP/SCADA Systems

- Automation level

- PLC/HMI Controlled

- Software integration

- Smart Factory Software

- Customization of machinery

- Modular Configuration