Semi-automatic lipstick moulding system

Streamline your lipstick production with a versatile system that effortlessly moulds, heats, doses, cools, and demoulds a variety of finishes, enhancing both efficiency and consistency in your processing line.

Moulds and Processes Lipstick Formulations

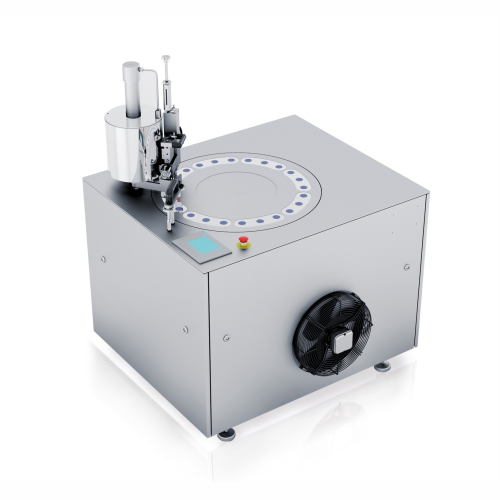

The SM 300 from Marchesini Group is a semi-automatic lipstick moulding machine that utilizes silicone mould technology to enhance production efficiency for cosmetic manufacturers. This equipment combines processes such as heating, dosing, cooling, and demoulding to consistently produce high-quality matte, glossy, sheer, cream, satin, and mineral lipsticks. Capable of achieving outputs of up to 300 pieces per hour, it integrates seamlessly into existing processing and packaging lines, providing smooth operation with its Siemens PLC control system.

The SM 300’s design features a single melting tank with a volumetric doser equipped with a fixed-type nozzle, ensuring precise dosing and minimal waste. The cooling system, able to reach -20°C via forced air circulation, is specifically engineered for optimal thermal management during moulding operations. This machine is ideal for semi-automatic operations and pilot production runs, offering customization and engineering support for unique production requirements.

Constructed to meet the high demands of the cosmetics industry, the SM 300 offers efficient material handling with 24 silicone moulds and ensures easy maintenance with straightforward operation controls. While not explicitly mentioned, users can expect compliance with typical industry standards, aligning with the quality expectations of beauty product and personal care manufacturers.

Benefits

- Enhances production efficiency by achieving up to 300 lipstick pieces per hour.

- Ensures consistent product quality with precise silicone mould technology.

- Minimizes operating costs through energy-efficient cooling to -20°C.

- Reduces labor involvement with user-friendly semi-automatic controls.

- Facilitates integration with existing lines for streamlined processing and packaging.

- Applications

- Cosmetics, Lipsticks

- End products

- Satin lipstick, Mineral lipstick, Sheer lipstick, Cream lipstick, Matte lipstick, Glossy lipstick

- Steps before

- Melting, Mould Heating

- Steps after

- Cooling, Demoulding, Packaging

- Input ingredients

- silicone mould, lipstick material, melting tank

- Output ingredients

- lipstick, packaged lipstick, demoulded lipstick

- Market info

- Marchesini (Cosmatic) is known for its expertise in designing and manufacturing customized machinery for the cosmetic industry, including equipment for filling, capping, and cartoning processes, earning a strong reputation for quality and innovation in the market.

- Capacity

- 300 pieces/hour

- Automation

- PLC-controlled

- Cooling System

- -20°C by forced air circulation

- Operator

- 1

- Silicone Moulds

- 24

- Melting Tank Capacity

- 5 liters

- Dosing Nozzle

- 1 nozzle, fix type

- Working mechanism

- Semi-automatic

- Automation level

- PLC-controlled

- Cooling system

- Forced air circulation

- Temperature control

- Cooling up to -20°C

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Operation type

- Semi-automatic

- Tank size

- 5 liters

- Cooling system

- Cooling up to -20°C by forced air circulation

- Number of molds

- 24 silicone molds

- Molding technology

- Silicone mold technology

- Control panel type

- Siemens PLC

- Control panel type

- Siemens PLC

- Cooling system

- Forced air circulation

- Customization of moulds

- 24 silicone moulds

- Operation type

- Semi-automatic